A method for controlling the cooling path of high-strength steel bars

A control method and cooling path technology, applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., to achieve the effect of reducing alloy content, improving mechanical properties, and prolonging solid solution state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Taking HRB400E as an example, the production High-strength steel bars, by weight percentage, include the following components:

[0024] Ingredient Control:

[0025]

[0026] The rest is Fe, control impurity content: P≤0.045%, S≤0.045%. Billet section specification: 160×160mm 2 , Rolling speed: 12m / s, rolling start temperature: around 1040°C.

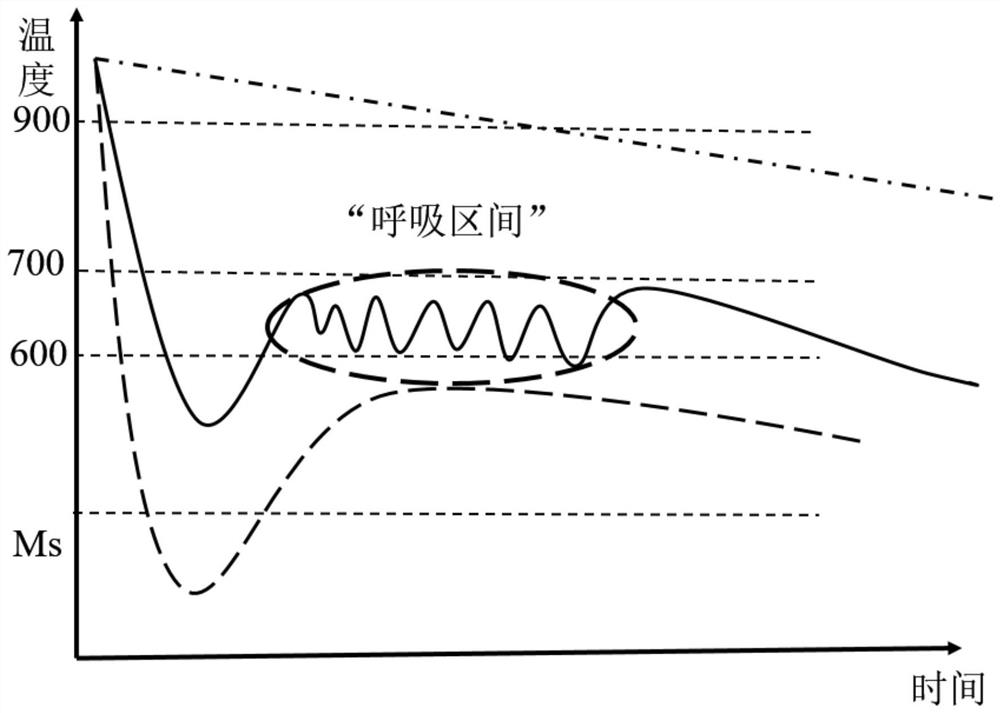

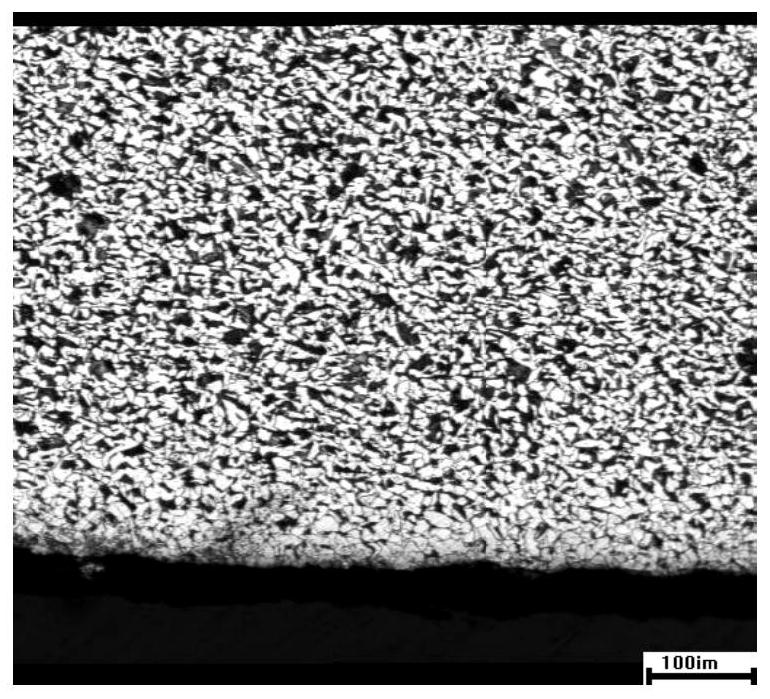

[0027] The cooling path after rolling adopts the alternate arrangement mode of large cooling speed water cooling and small cooling speed water mist cooling unit. The length of the large cooling cooling unit is 4m, and the length of small cooling speed water mist cooling unit is 5m. Large cooling speed - small cooling speed - large cooling speed - small cooling speed layout, a total of 27m, the cooling speed of the large cooling speed is about 22 ℃ / s, the cooling speed of the small cooling speed is about 12 ℃ / s, the total cooling time is about In 2.5s, the target temperature of the upper cooling bed is controlled at abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com