Narrow-range production control method of rare earth elements La and Ce in rare earth bearing steel

A production control method and rare earth element technology, applied in the field of metallurgy, can solve the problems of inability to precisely control the content of rare earth elements, inability to achieve on-site batch production of water plugging ports, unstable yield of rare earth elements, etc., so as to reduce production costs and improve purity. degree, the effect of promoting floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

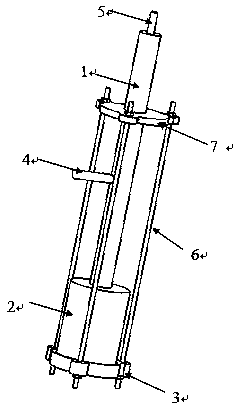

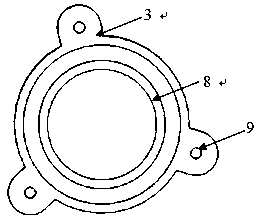

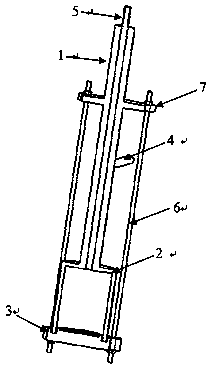

Image

Examples

Embodiment 1

[0030] The narrow-range production control method of rare earth elements La and Ce in rare earth bearing steel in this embodiment includes converter smelting, LF ladle refining, VD vacuum refining, and continuous casting processes. The specific process steps are as follows:

[0031] (1) Converter smelting process: add aluminum ingots and lime for deoxidation during the tapping process of the converter, carry out slag removal treatment after tapping, and add lime and pre-melted refining slag after slag removal to form CaO / SiO 2 High-basic refining slag with a binary basicity of 8.8; white ash CaO: 92.3%; pre-melted refining slag composition: CaO: 53%, SiO 2 : 3.2%, Al 2 o 3 : 38.6%, S: 0.08%; the composition of high alkalinity refining slag is: CaO: 55.4%, SiO 2 : 6.3%, Al 2 o 3 : 31.1%;

[0032](2) LF ladle refining process: During the LF ladle refining process, high-grade silicon carbide is used for diffusion deoxidation, SiC: 72.3%, large argon gas is used for strong st...

Embodiment 2

[0037] The narrow-range production control method of rare earth elements La and Ce in rare earth bearing steel in this embodiment includes converter smelting, LF ladle refining, VD vacuum refining, and continuous casting processes. The specific process steps are as follows:

[0038] (1) Converter smelting process: add aluminum ingots and lime for deoxidation during the tapping process of the converter, carry out slag removal treatment after tapping, and add lime and pre-melted refining slag after slag removal to form CaO / SiO 2 High-basic refining slag with a binary basicity of 8.1; white ash CaO: 90.1%; pre-melted refining slag composition: CaO: 53.7%, SiO 2 : 3.6%, Al 2 o 3 : 39.5%, S: 0.05%; the composition of high alkalinity refining slag is: CaO: 55.91%, SiO 2 : 6.88%, Al 2 o 3 : 30.5%;

[0039] (2) LF ladle refining process: During the LF ladle refining process, high-grade silicon carbide is used for diffusion deoxidation, SiC: 75.2%, large argon gas is used for stro...

Embodiment 3

[0044] The narrow-range production control method of rare earth elements La and Ce in rare earth bearing steel in this embodiment includes converter smelting, LF ladle refining, VD vacuum refining, and continuous casting processes. The specific process steps are as follows:

[0045] (1) Converter smelting process: add aluminum ingots and lime for deoxidation during the tapping process of the converter, carry out slag removal treatment after tapping, and add lime and pre-melted refining slag after slag removal to form CaO / SiO 2 High-basic refining slag with a binary basicity of 8.1; white ash CaO: 90.6%; pre-melted refining slag composition: CaO: 53.7%, SiO 2 : 3.8%, Al 2 o 3 : 39.5%, S: 0.07%; the composition of high alkalinity refining slag is: CaO: 53.66%, SiO 2 : 5.95%, Al 2 o 3 : 31%;

[0046] (2) LF ladle refining process: During the LF ladle refining process, high-grade silicon carbide is used for diffusion deoxidation, SiC: 71.8%, large argon gas is used for strong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com