A kind of electrolytic solution for micro-arc oxidation black ceramic film and its preparation method and micro-arc oxidation method

A technology of micro-arc oxidation and black ceramics, applied in the direction of electrolytic coating, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problems of uneven distribution of coloring ions, porous film, etc., and achieve blackness saturation and controllable thickness , good process repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

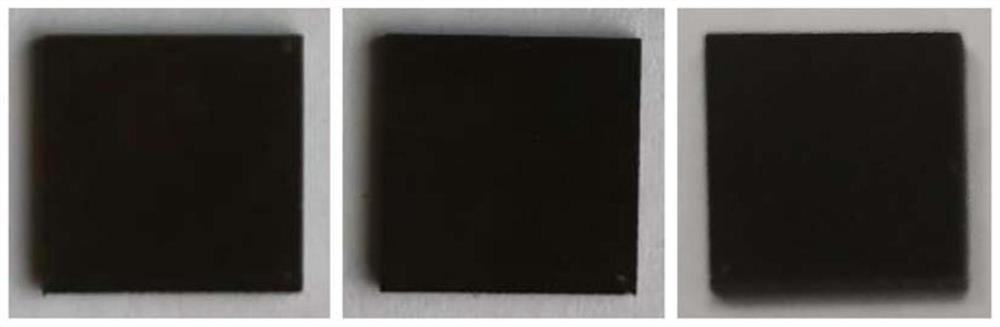

Embodiment 1

[0033] (1) After cutting the AZ91 magnesium alloy wire into a sample with a length × width × height of 10mm × 10mm × 2mm, and using 400, 500, 800, 1000, 1500 mesh SiC sandpaper on the pre-grinder to remove the surface oxide film step by step , wash with acetone for 5 minutes to remove oil, then use distilled water for ultrasonic cleaning for 5 minutes to remove surface impurities, wash with ethanol to remove water, and finally dry it for later use.

[0034](2) First take 1L of deionized water and pour it into the oxidation tank, then add 24g of sodium silicate, 12g of sodium fluoride and 4g of sodium hexametaphosphate in sequence, and carry out the dispersion treatment with a high-speed homogenizer in an ice-water bath at 0°C for 10 to 15 minutes. Prepare the first coloring solution; take 1L of deionized water and pour it into a beaker, add 8g of potassium sodium tartrate and 8g of copper pyrophosphate in turn, and perform magnetic stirring and hydrolysis treatment in a constan...

Embodiment 2

[0037] (1) After cutting the AZ91 magnesium alloy wire into a sample with a length × width × height of 10mm × 10mm × 2mm, and using 400, 500, 800, 1000, 1500 mesh SiC sandpaper on the pre-grinder to remove the surface oxide film step by step , wash with acetone for 5 minutes to remove oil, then use distilled water for ultrasonic cleaning for 5 minutes to remove surface impurities, wash with ethanol to remove water, and finally dry it for later use.

[0038] (2) First take 1L of deionized water and pour it into the oxidation tank, then add 30g of sodium silicate, 15g of sodium fluoride and 5g of sodium trimetaphosphate in turn, and carry out the dispersion treatment with a high-speed homogenizer in an ice-water bath at 0°C for 10 to 15 minutes. Prepare the first coloring solution; take 1L of deionized water and pour it into a beaker, add 10g of potassium sodium tartrate and 10g of copper phosphate in sequence, and magnetically stir and hydrolyze it in a constant temperature wate...

Embodiment 3

[0041] (1) After cutting the AZ91 magnesium alloy wire into a sample with a length × width × height of 10mm × 10mm × 2mm, and using 400, 500, 800, 1000, 1500 mesh SiC sandpaper on the pre-grinder to remove the surface oxide film step by step , wash with acetone for 5 minutes to remove oil, then use distilled water for ultrasonic cleaning for 5 minutes to remove surface impurities, wash with ethanol to remove water, and finally dry it for later use.

[0042] (2) First take 1L of deionized water and pour it into the oxidation tank, then add 32g of sodium silicate, 20g of sodium fluoride and 4g of sodium phosphate in sequence, and carry out dispersing treatment with a high-speed homogenizer in an ice-water bath environment at 0°C for 10 to 15 minutes to obtain The first coloring solution: take 1L of deionized water and pour it into a beaker, add 10g of potassium sodium tartrate and 12g of copper carbonate in turn, and magnetically stir and hydrolyze it in a constant temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com