Catalyst for hydrogen production by methanol steam reforming and preparation method and application thereof

A steam reforming and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high price, limited hydrogen source, poor stability, etc. , to achieve the effects of easy large-scale production, large-scale production, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

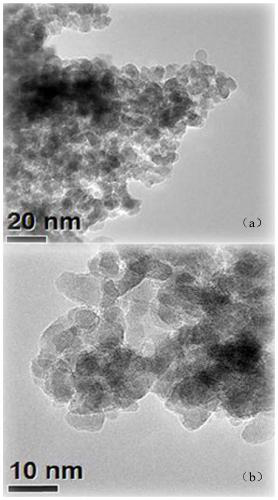

Image

Examples

Embodiment 1

[0044] A catalyst for hydrogen production by steam reforming of methanol, the copper-zirconium component is supported on the hard template activated carbon by co-precipitation method, and then the porous Cu / ZrO prepared by removing the activated carbon 2 Catalyst, and further exposure of sufficient copper-zirconium interface by pickling treatment. The main components of the catalyst are Cu and ZrO 2 , the basic composition of the catalyst is calculated by the molar percentage of Cu, Zr metal atoms (metal atoms total 100%), specifically as follows:

[0045] Cu 5%,

[0046] Zr 95%.

[0047] Above-mentioned a kind of preparation method for hydrogen production by steam reforming of methanol specifically comprises the following steps:

[0048] 0.46g Cu(NO 3 ) 2 .3H 2 O with 13.27g ZrOCl 2 .8H 2 O is dissolved in the water of 83mL and makes mixed solution, the Na of 1mol / L of this mixed solution 105mL 2 CO 3 Add the solution dropwise to the solution containing 1.5g of acti...

Embodiment 2

[0051] A catalyst for hydrogen production by steam reforming of methanol, the copper-zirconium component is supported on the hard template activated carbon by co-precipitation method, and then the porous Cu / ZrO prepared by removing the activated carbon 2 Catalyst, and further exposure of sufficient copper-zirconium interface by pickling treatment. The main components of the catalyst are Cu and ZrO 2 , the basic composition of the catalyst is calculated by the molar percentage of Cu, Zr metal atoms, as follows:

[0052] Cu 12%,

[0053] Zr 88%.

[0054] Above-mentioned a kind of preparation method for hydrogen production by steam reforming of methanol specifically comprises the following steps:

[0055] 1.13g Cu(NO 3 ) 2 .3H 2 O with 12.61g ZrOCl 2 .8H 2 O is dissolved in the water of 85mL and makes mixed solution, the Na of 1mol / L of this mixed solution 105mL 2 CO 3 The solution was added dropwise to the solution containing 2.03g of activated carbon powder and 20mL o...

Embodiment 3

[0058] A catalyst for hydrogen production by steam reforming of methanol, the copper-zirconium component is supported on the hard template activated carbon by co-precipitation method, and then the porous Cu / ZrO prepared by removing the activated carbon 2 Catalyst, and further exposure of sufficient copper-zirconium interface by pickling treatment. The main components of the catalyst are Cu and ZrO 2 , the basic composition of the catalyst is calculated by the molar percentage of Cu, Zr metal atoms, as follows:

[0059] Cu 20%,

[0060] Zr 80%.

[0061] Above-mentioned a kind of preparation method for hydrogen production by steam reforming of methanol specifically comprises the following steps:

[0062] 1.94g Cu(NO 3 ) 2 .3H 2 O with 11.81g ZrOCl 2 .8H 2 O is dissolved in the water of 87mL and makes mixed solution, the Na of 1mol / L of this mixed solution 103mL 2 CO 3 Add the solution dropwise to the solution containing 2.10g of activated carbon powder and 20mL of 0.3m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com