Catalyst suitable for producing acrolein, and applications thereof

A catalyst, acrolein technology, applied in physical/chemical process catalysts, heterogeneous catalyst chemical elements, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low yield of acrolein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

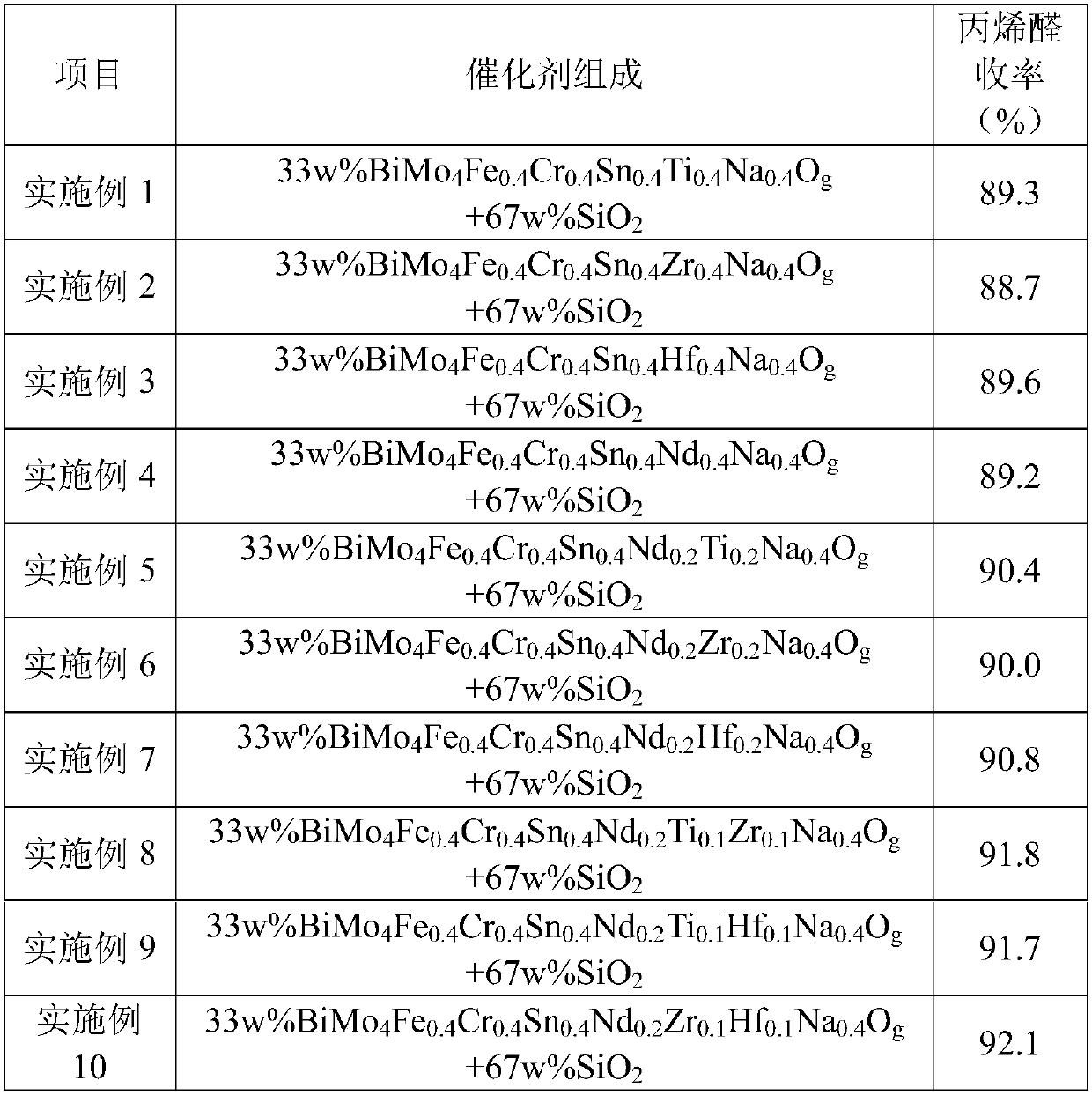

Examples

Embodiment 1

[0066] 1. Catalyst preparation

[0067] Bismuth nitrate (molecular formula is: Bi(NO 3 ) 3 ) was dissolved in 200g of hot water at 80°C. Ammonium molybdate (molecular formula is: (NH 4 ) 2 MoO 4 ) into it, and then respectively add chromium nitrate containing 0.04 moles of Cr (molecular formula: Cr(NO 3 ) 3 ), tin dioxide containing 0.04 moles of Sn (molecular formula: SnO 2 ), titanium dioxide containing 0.04 moles of Ti (molecular formula: TiO 2 ), containing 0.04 moles of Na sodium nitrate (molecular formula is NaNO 3 ), stirred to make it all dissolve to obtain solution I. Ferric nitrate containing 0.04 moles of Fe (molecular formula is: Fe(NO 3 ) 3 ) aqueous solution was added to the above solution, mixed evenly, and evaporated at 80°C until the mixture containing the active component BiMo 4 Fe 0.4 Cr 0.4 sn 0.4 Ti 0.4 Na 0.4 o g The concentration of 0.4g / g, to obtain solution II.

[0068] Mix 200 g of spherical silica carrier with a diameter of 5 mm an...

Embodiment 2

[0079] 1. Catalyst preparation

[0080] Bismuth nitrate (molecular formula is: Bi(NO 3 ) 3 ) was dissolved in 200g of hot water at 80°C. Ammonium molybdate (molecular formula is: (NH 4 ) 2 MoO 4 ) into it, and then respectively add chromium nitrate containing 0.04 moles of Cr (molecular formula: Cr(NO 3 ) 3 ), tin dioxide containing 0.04 moles of Sn (molecular formula: SnO 2 ), zirconium nitrate (molecular formula: Zr(NO 3 ) 4 ), containing 0.04 moles of Na sodium nitrate (molecular formula is NaNO 3 ), stirred to make it all dissolve to obtain solution I. Ferric nitrate containing 0.04 moles of Fe (molecular formula is: Fe(NO 3 ) 3 ) aqueous solution was added to the above solution, mixed evenly, and evaporated at 80°C until the mixture containing the active component BiMo 4 Fe 0.4 Cr 0.4 sn 0.4 Zr 0.4 Na 0.4 o g The concentration of 0.4g / g, to obtain solution II.

[0081] Mix 200 g of spherical silica carrier with a diameter of 5 mm and 200 g of solution ...

Embodiment 3

[0092] 1. Catalyst preparation

[0093] Bismuth nitrate (molecular formula is: Bi(NO 3 ) 3 ) was dissolved in 200g of hot water at 80°C. Ammonium molybdate (molecular formula is: (NH 4 ) 2 MoO4 ) into it, and then respectively add chromium nitrate containing 0.04 moles of Cr (molecular formula: Cr(NO 3 ) 3 ), tin dioxide containing 0.04 moles of Sn (molecular formula: SnO 2 ), hafnium oxide containing 0.04 moles of Hf (molecular formula: HfO 2 ), containing 0.04 moles of Na sodium nitrate (molecular formula is NaNO 3 ), stirred to make it all dissolve to obtain solution I. Ferric nitrate containing 0.04 moles of Fe (molecular formula is: Fe(NO 3 ) 3 ) aqueous solution was added to the above solution, mixed evenly, and evaporated at 80°C until the mixture containing the active component BiMo 4 Fe 0.4 Cr 0.4 sn 0.4 Hf 0.4 Na 0.4 o g The concentration of 0.4g / g, to obtain solution II.

[0094] Mix 200 g of spherical silica carrier with a diameter of 5 mm and 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com