Preparation method and application of metal MOF-based composite material

A composite material and metal technology, which is applied in the field of preparation of metal MOF-based composite materials, can solve the problems of platinum nanoparticle loss, agglomeration, and increase the cost of fuel cells, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

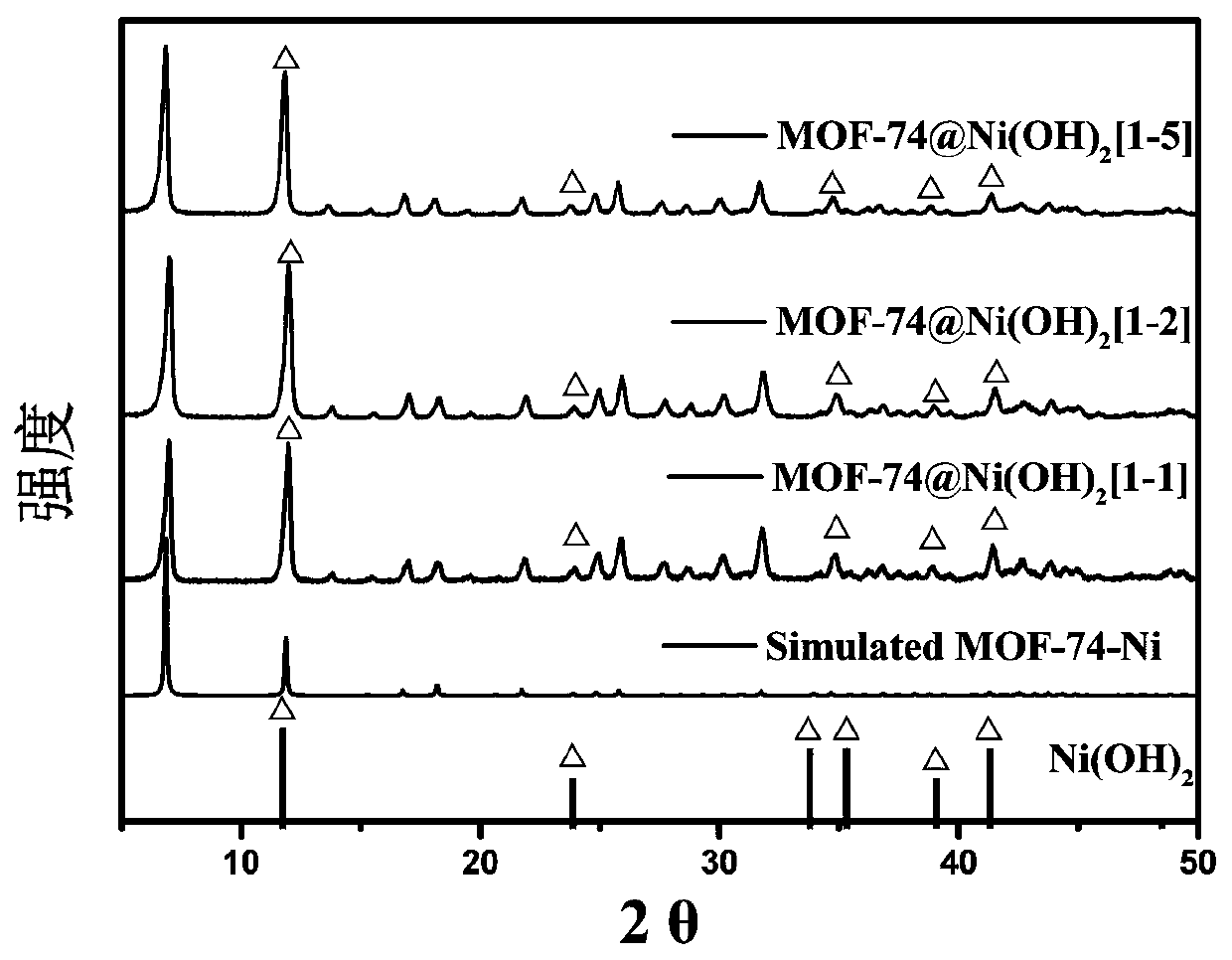

[0038] Dissolve (1 mmol) 220 mg of 2,5-dihydroxyterephthalic acid in 7.5 ml of DMF / H 2 O / EtOH volume ratio is (1 / 1 / 1) in a solvent system to form solution A; put (0.4 mmol) 36.0 mg of nickel hydroxide into solution A to form solution B;

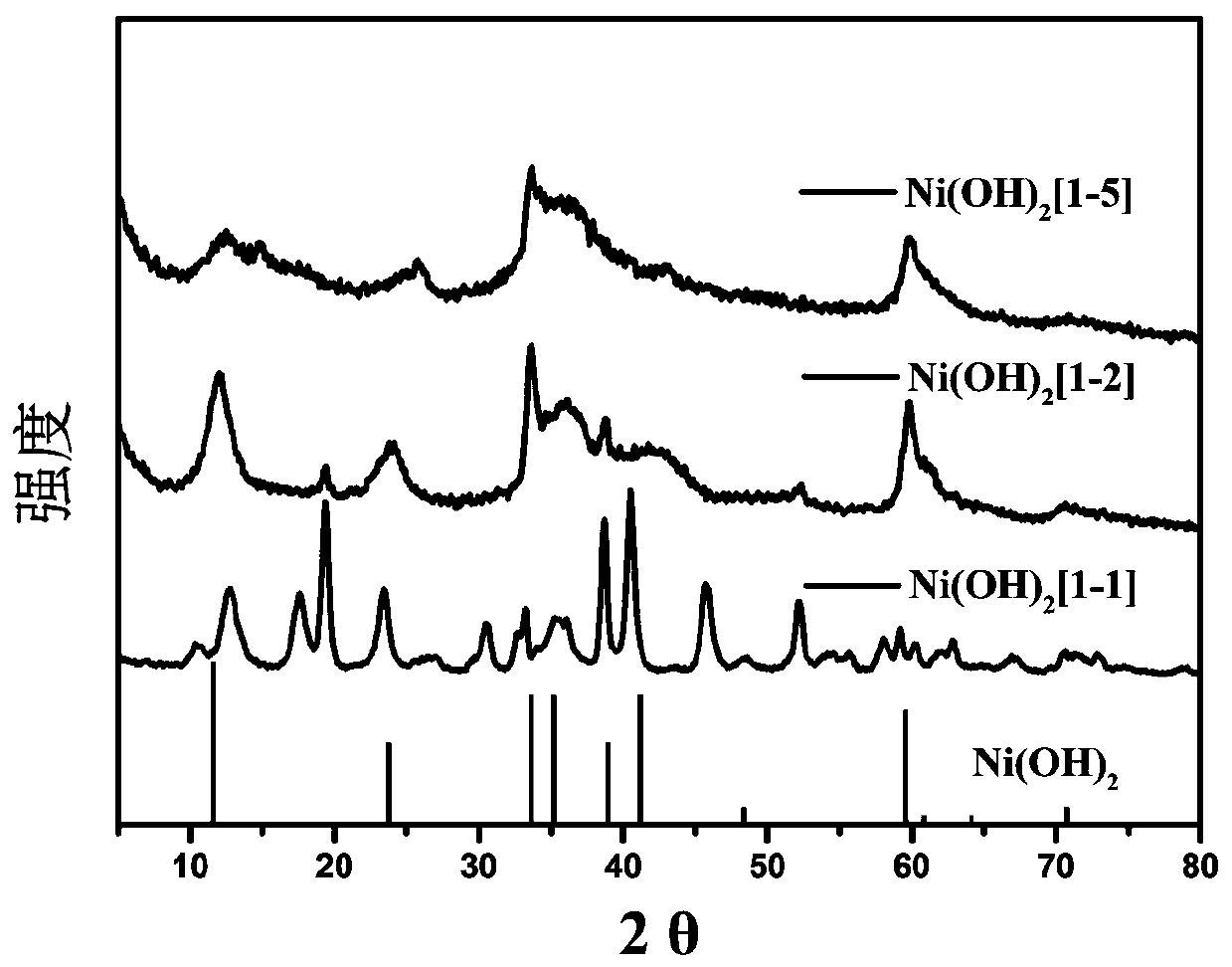

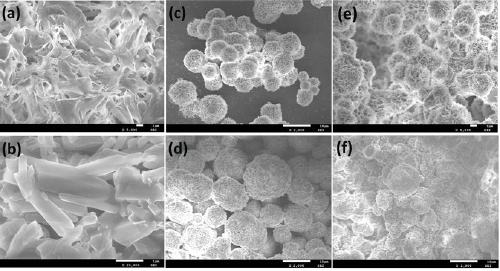

[0039] The petal-shaped nickel hydroxide is a precursor prepared by synthesis of a specific metal salt and urea, specifically, 0.01mol (264mg) nickel sulfate is mixed with 0.01mol, 0.02mol, 0.05mol (60mg, 120mg, 300mg) of urea was dissolved in 30ml of deionized water. After mixing and ultrasonication, the resulting mixed solution was placed in a polytetrafluoroethylene reaction liner and reacted at 180°C for 18 hours. After the product was centrifuged, it was washed with ethanol and deionized water in turn. , and finally vacuum-dried to obtain a petal-shaped nickel hydroxide material, which is named Ni(OH) after adding 0.01mol, 0.02mol, and 0.05mol of urea according to the amount of urea added. 2 [1-1], Ni(OH) 2 [1-2], Ni(OH) 2 [1-5], the ...

Embodiment 2

[0045] Dissolve (1 mmol) 220 mg of 2,5-dihydroxyterephthalic acid in DMF / H 2 In the O / EtOH volume ratio (1 / 1 / 1) solvent system, a solution A was formed; 37.0 mg (0.4 mmol) of heterometal hydroxide Ni 1-x Cu(OH) x Put into solution A to form solution B;

[0046] The heterometallic hydroxide is a precursor prepared by synthesis of a specific metal salt and urea, wherein sulfate (nickel sulfate and copper sulfate) includes 6 proportions, 0% (comparison group) is 0% copper sulfate; 10% is 0.9mmol (237.6mg) nickel sulfate and 0.1mmol (25mg) copper sulfate; 20% is 0.8mmol (211mg) nickel sulfate and 0.2mmol (50mg) copper sulfate; 30% is 0.7mmol (184.8mg) nickel sulfate and 0.3mmol (75mg) copper sulfate; 40% is 0.6mmol (158mg) nickel sulfate and 0.4mmol (100mg) copper sulfate; 50% is 0.5mmol (132mg) nickel sulfate and 0.5mmol (125mg) copper sulfate. Specifically, dissolve 1mmol of sulfate (nickel sulfate and copper sulfate) and 0.02mol~0.05mol (120 mg~300mg) of urea in 30ml of deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com