Epoxy resin curing agent and preparation method thereof

A technology of epoxy resin curing and manufacturing method, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve problems such as reducing production costs, increasing the difficulty of filtration, and being unfavorable for cleaning, so as to reduce production costs, The effect of improving thermal performance and avoiding the risk of high temperature and high pressure synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

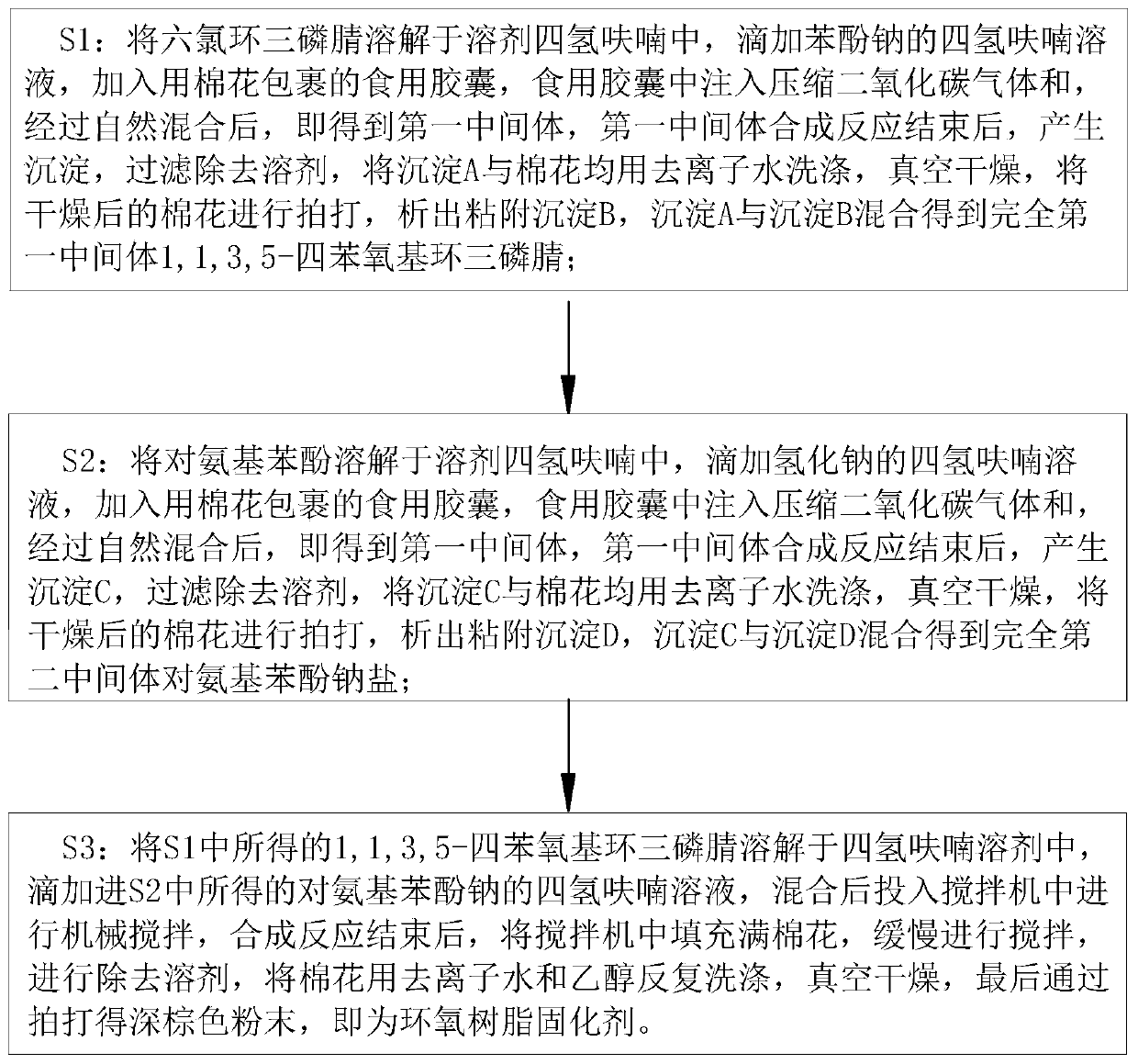

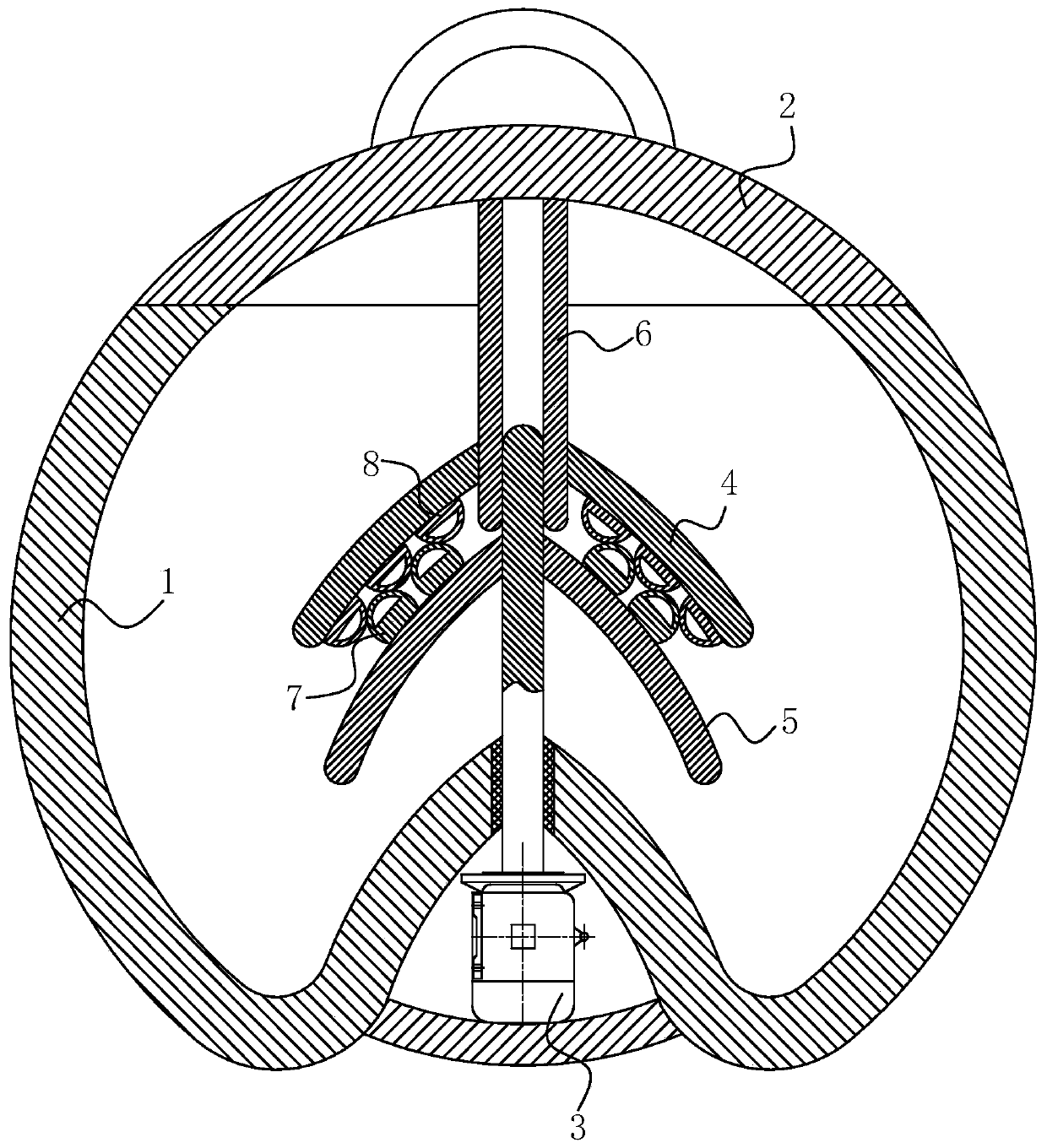

[0026] use Figure 1-Figure 2 An epoxy resin curing agent and its manufacturing method according to one embodiment of the present invention will be described as follows.

[0027] Such as Figure 1-Figure 2 Shown, a kind of epoxy resin curing agent described in the present invention comprises the following components of each weight part:

[0028] 20 parts of hexachlorocyclotriphosphazene, 5 parts of tetrahydrofuran, 2 parts of sodium phenate, 5 parts of deionized water, 2 parts of aminophenol, 3 parts of sodium hydride, 10 parts of ethyl maltol, and the chemical name is Ethylmaltol 2-Ethyl-3-hydroxy-4H-pyranone-[4] (2-ethyl-3-hydro}y-4H-pyran-4-one), the molecular formula is C7H8O3, and the molecular weight is 140.14. Ethyl maltol CAS NO:4940-11-8, white needle-like or white crystalline powder, it is easily soluble in water, and can well adjust the odor defects caused by chemical products.

[0029] A kind of manufacture method of epoxy resin curing agent, comprises the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com