Water-based paint and preparation method thereof

A water-based paint and water-based technology, applied in the field of paint, can solve the problems of low fullness and poor transparency, and achieve the effect of high fullness, delicate surface and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A preparation method of water-based paint includes the following steps:

[0057] S01. Prepare materials according to the above-mentioned water-based paint;

[0058] S02, subjecting the aqueous hydroxy acrylic emulsion, the aqueous polyurethane dispersion, the dispersant, the defoamer, the bactericide, the pH adjuster and part of the thickening agent to the first mixing process, to obtain the first mixture;

[0059] S03. Add a leveling agent, alcohol ether, wetting agent, water, and the remaining thickener to the first mixture, and perform a second mixing process to obtain a main ingredient;

[0060] S04. Mix the main material and the water-dispersible hexamethylene diisocyanate homopolymer to obtain the water-based paint.

[0061] In the preparation method of the water-based paint provided by the embodiment of the present invention, each component in the main ingredient formulation is mixed, and then the main ingredient and the water-dispersible hexamethylene diisocyanate homopol...

Embodiment 1

[0070] This embodiment provides a two-component polyurethane water-based coating, including: a main agent and a water-dispersible hexamethylene diisocyanate homopolymer;

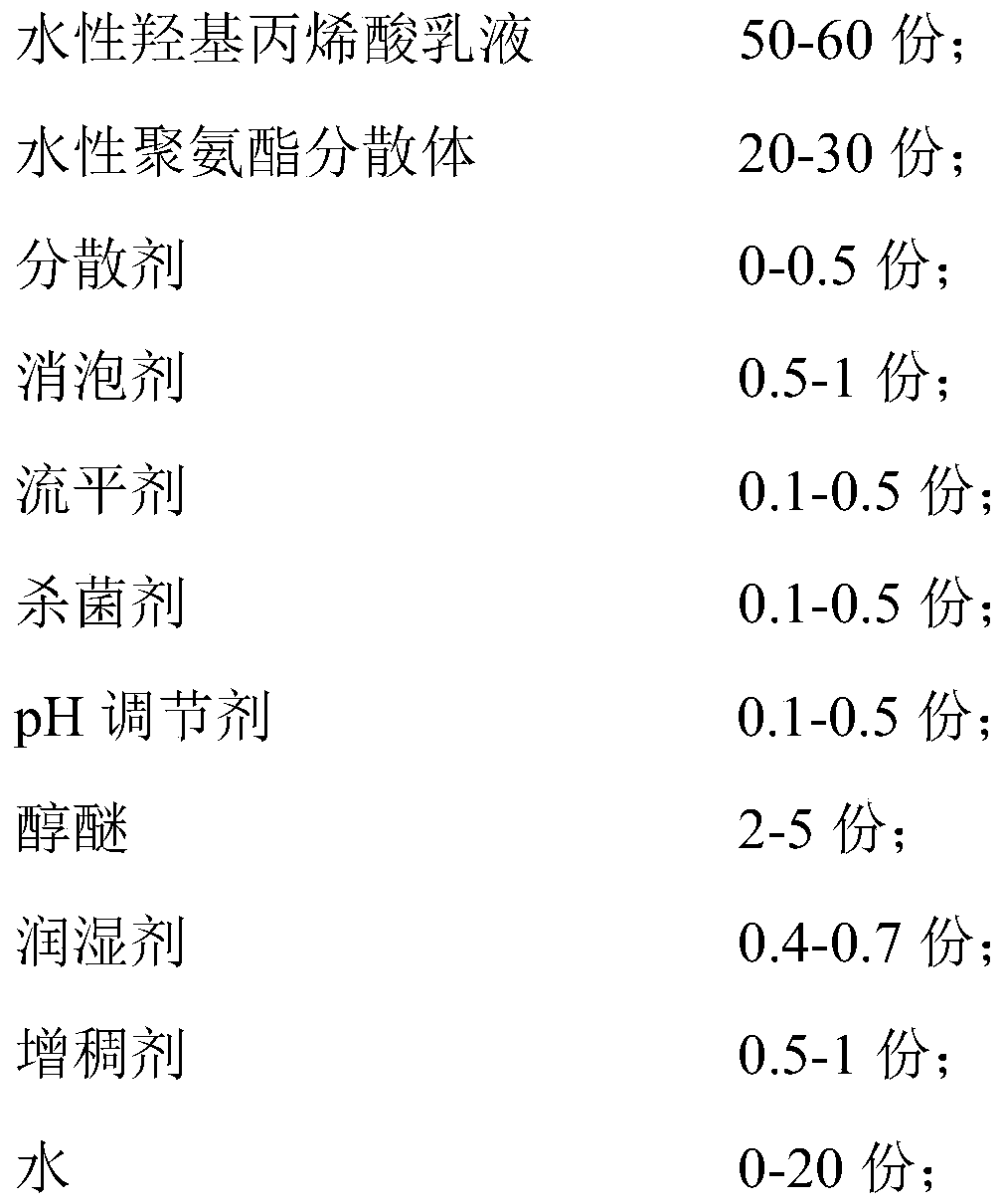

[0071] Wherein, based on the total weight of the main agent as 100 parts, the main agent includes the following components by weight:

[0072]

[0073] The proportion of each component is the main paint: curing agent: water = 100: 10: 10 (mass ratio)

Embodiment 2

[0075] This embodiment provides a two-component polyurethane water-based coating, including: a main agent and a water-dispersible hexamethylene diisocyanate homopolymer;

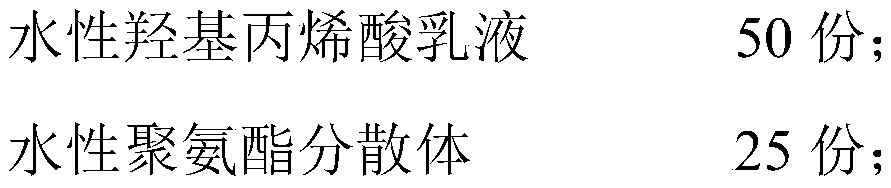

[0076] Wherein, based on the total weight of the main agent as 100 parts, the main agent includes the following components by weight:

[0077]

[0078] The proportion of each component is the main paint: curing agent: water = 100: 10: 10 (mass ratio)

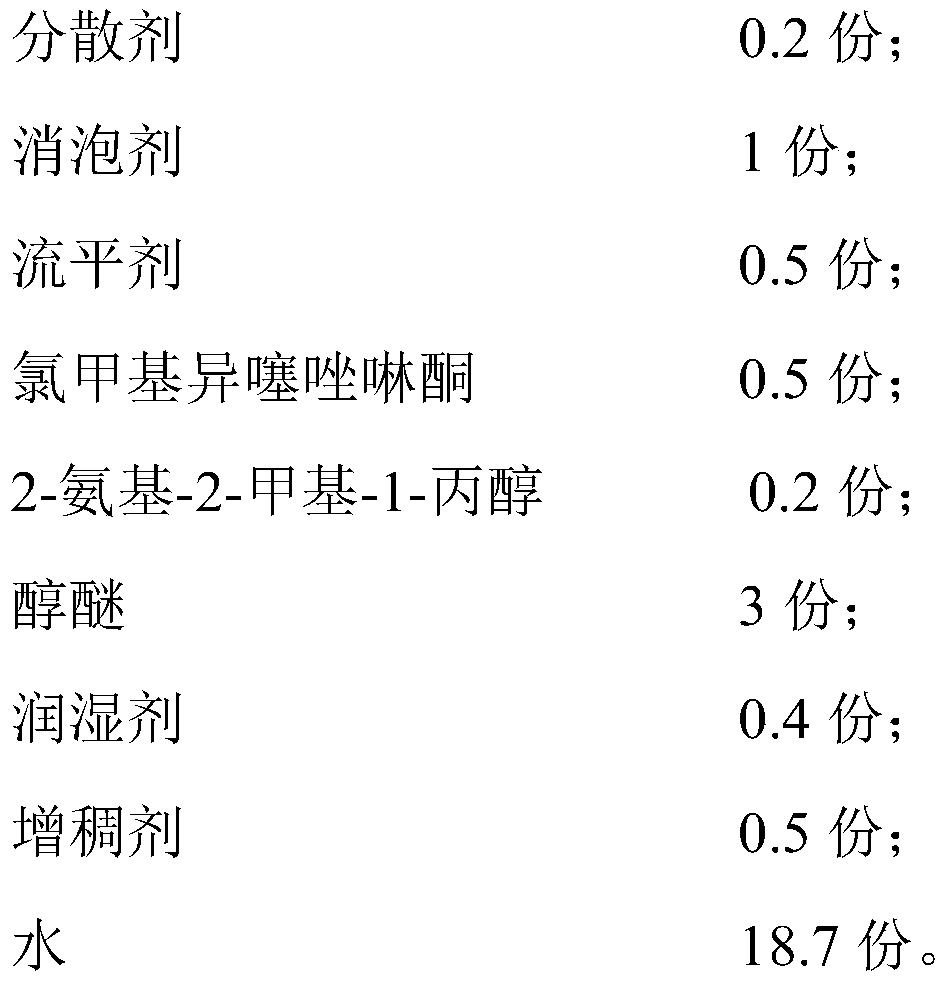

[0079] 1. Take the two-component polyurethane water-based paint prepared in Example 1 and Example 2, according to the water-based paint performance standard GB / T23999-2009 "Water-based wood coating for interior decoration" and GB24410-2009 "Water-based wood coating for interior decoration" Coating Hazardous Substances Limitation” was tested, and the test results are shown in Table 1, showing that the coatings provided in the embodiments of the present invention meet the national standards.

[0080] Table 1

[0081]

[0082]

[0083] 2. Take the two-component polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com