Method for preparing carbon-containing compound by electro-catalyzing carbon dioxide with copper alloy material

A technology of hydrocarbons and copper alloys, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of unsatisfactory catalytic selectivity and poor stability of multi-carbon compounds , activity reduction and other issues, to achieve the effect suitable for industrialization promotion and application, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The invention provides a kind of synthetic method of carbon-containing compound, comprises the following steps:

[0076] Copper alloy materials with amorphous structure were used as catalysts to convert CO 2 After electrochemical reaction, carbon-containing compounds are obtained.

[0077] In principle, the present invention has no special restrictions on the copper content of the copper alloy material having an amorphous structure. Those skilled in the art can select and adjust according to actual conditions, electrolysis requirements and product requirements. The present invention is to better ensure the electrochemical reaction progress, improve the electrocatalytic activity and stability of the catalyst, and then improve the performance and efficiency of the electrolytic cell, more effectively exert the synergistic catalytic performance between the catalysts, better regulate the types of products and improve the Faraday effect, and the amorphous The content of copp...

Embodiment 1

[0131] A preparation method of copper alloy Cu-Ti electrocatalytic electrode, comprising the following steps:

[0132] Step 1: Put Cu and Ti in a high-temperature melting furnace, the molar ratio of copper and titanium is 50:50, stir evenly after melting, and cool down to obtain an electrocatalytic electrode alloy;

[0133] Step 2: Melt the alloy obtained in Step 1 again, and carry out liquid-phase quenching on a rotating copper disk with a cooling rate of 10 5 K / s, the rotation speed is 2000rpm, and the amorphous Cu-Ti electrocatalytic electrode is obtained;

[0134] Step 3: Soak the amorphous electrocatalytic electrode obtained in Step 2 in a 50 mM hydrofluoric acid solution, and react at 25° C. for 12 hours to obtain a copper alloy catalytic electrode.

[0135] The copper alloy electrocatalytic electrode prepared in Example 1 of the present invention was scanned and tested, and the model of the scanning electron microscope was FEI Quanata 200FEG.

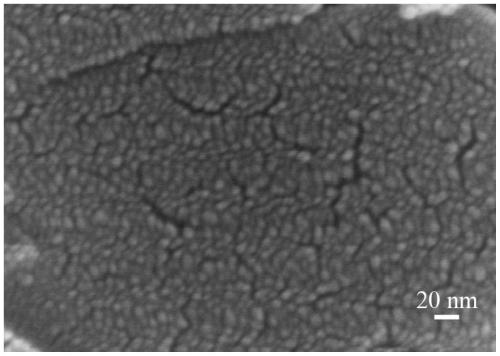

[0136] see figure 1 , ...

Embodiment 2

[0144] A method for preparing a copper alloy Cu-Ti electrocatalytic electrode is basically the same as in Example 1, the difference is only in the molar ratio of elements in step 1, the molar ratio of copper and titanium is 70:30.

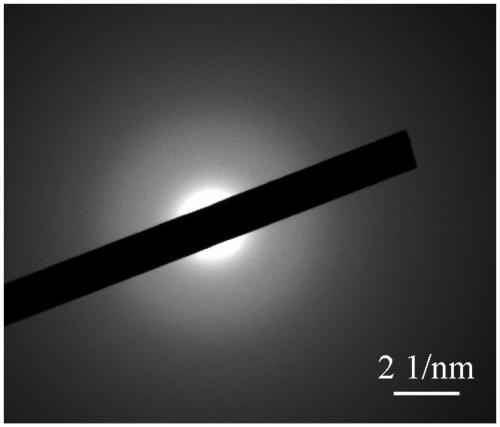

[0145] Scanning test and transmission electron microscope test were carried out on the copper alloy electrocatalytic electrode prepared in Example 2 of the present invention. The model of the scanning electron microscope is FEI Quanata 200FEG, and the model of the transmission electron microscope is JEM-2100F.

[0146] From the characterization results, the catalytic electrode prepared in Example 2 is also specifically as follows: figure 1 Similar nanoscale pores in and figure 2 Amorphous properties in .

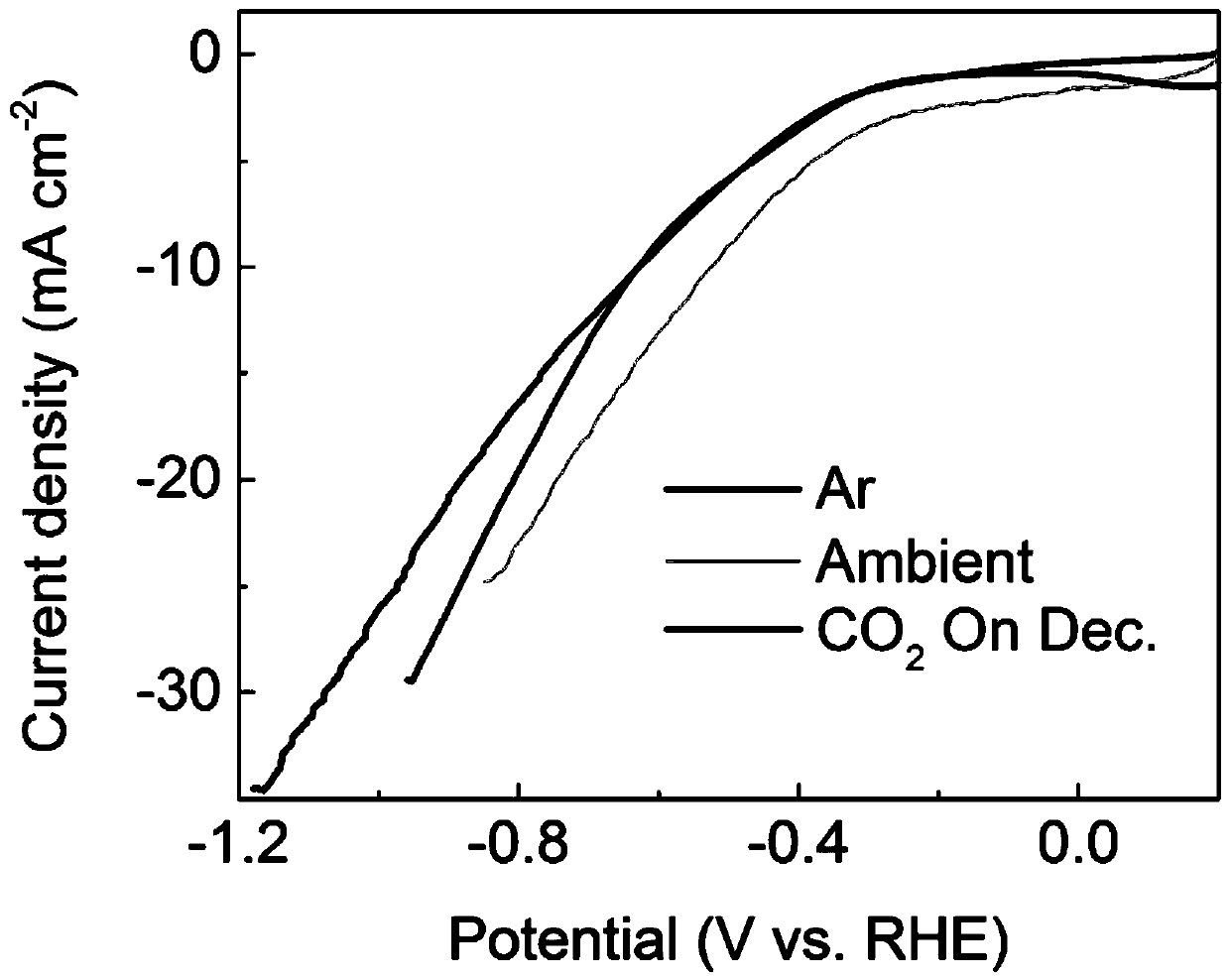

[0147] The electrocatalytic electrode prepared in Example 2 of the present invention was subjected to CO 2 RR test, test CO 2 Electrocatalytic reduction performance.

[0148] The performance test was carried out in a three-electrode system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com