Hydrophobic slurry as well as preparation method and application thereof

A hydrophobic and slurry technology, which is applied in the direction of paper coating, water-repellent agent addition, pigmented coating, etc., can solve the problems of unfavorable environmental protection, harsh preparation conditions, non-biodegradable, etc., achieve excellent hydrophobic performance, easy preparation, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a kind of hydrophobic slurry, which is specifically prepared by the following steps:

[0064] Add 3g (dry weight) nanocellulose (particle size 1-50nm; aspect ratio 100-200) into 200g deionized water, stir and disperse at room temperature 25°C, then add 0.2g sodium lauryl sulfate, and then carry out Stir at high speed at 4500 rpm for 8 minutes, then add 4 g of stearic acid, heat to 85 degrees Celsius, and then carry out stirring and emulsification. The rotation speed of stirring and emulsification is 10,000 rpm, and the emulsification time is 10 minutes. The particle size is 1.18 microns, and the PDI is 0.91. After 20 days at 25°C, there is no obvious change in appearance, the particle size is 1.21 microns, and the PDI is 0.94. It can be seen that the emulsion particles in the hydrophobic slurry prepared in this example are small and stable Good sex.

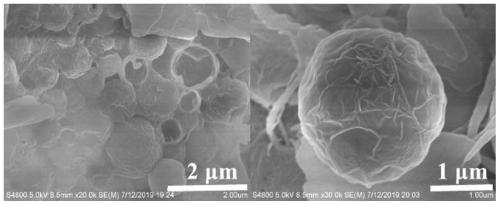

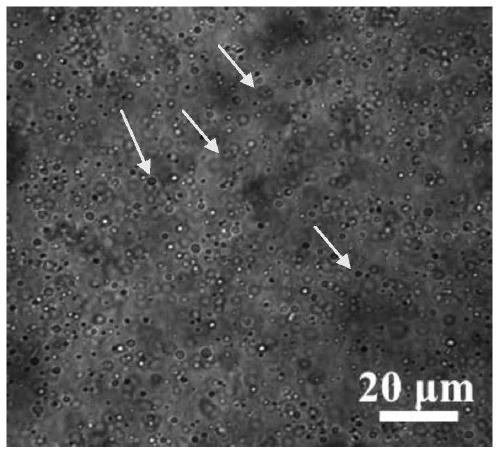

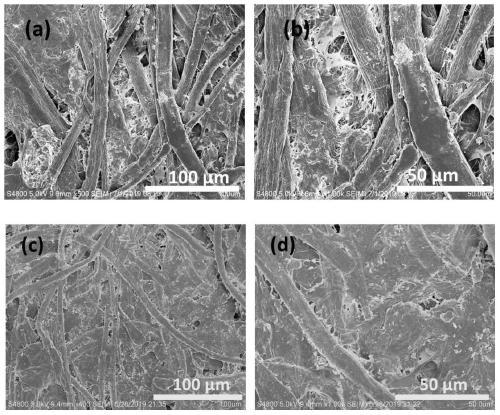

[0065] After freeze-drying the hydrophobic slurry prepared above, carry out electron microscop...

Embodiment 2

[0071] This embodiment provides a hydrophobic pulp and hydrophobic paper, which are prepared in the same way as in Embodiment 1, except that hydroxyethyl cellulose (DP of 180) is used instead of nanocellulose.

[0072] The prepared Pickering-type hydrophobic slurry is a milky white uniform liquid, in which the particle size of the milk particles is 1.26 microns, and the PDI is 0.86. After 20 days at 25°C, the appearance is milky white liquid but there is layering at the bottom. After shaking and mixing evenly , the emulsion was restored to its original state, the particle size was 1.53 microns, and the PDI was 0.98.

Embodiment 3

[0074] This embodiment provides a kind of hydrophobic slurry and hydrophobic paper, and its preparation method is the same as that of Example 1, the only difference is that the solid particles used in this embodiment are 1g of nanocellulose and 2g of microcrystalline cellulose (DP for 220).

[0075] The prepared Pickering-type hydrophobic slurry is a milky white uniform liquid, in which the particle size of the milk particles is 0.98 microns, and the PDI is 0.86. After 20 days at 25°C, there is no obvious change in appearance, the particle size is 1.07 microns, and the PDI is 0.90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com