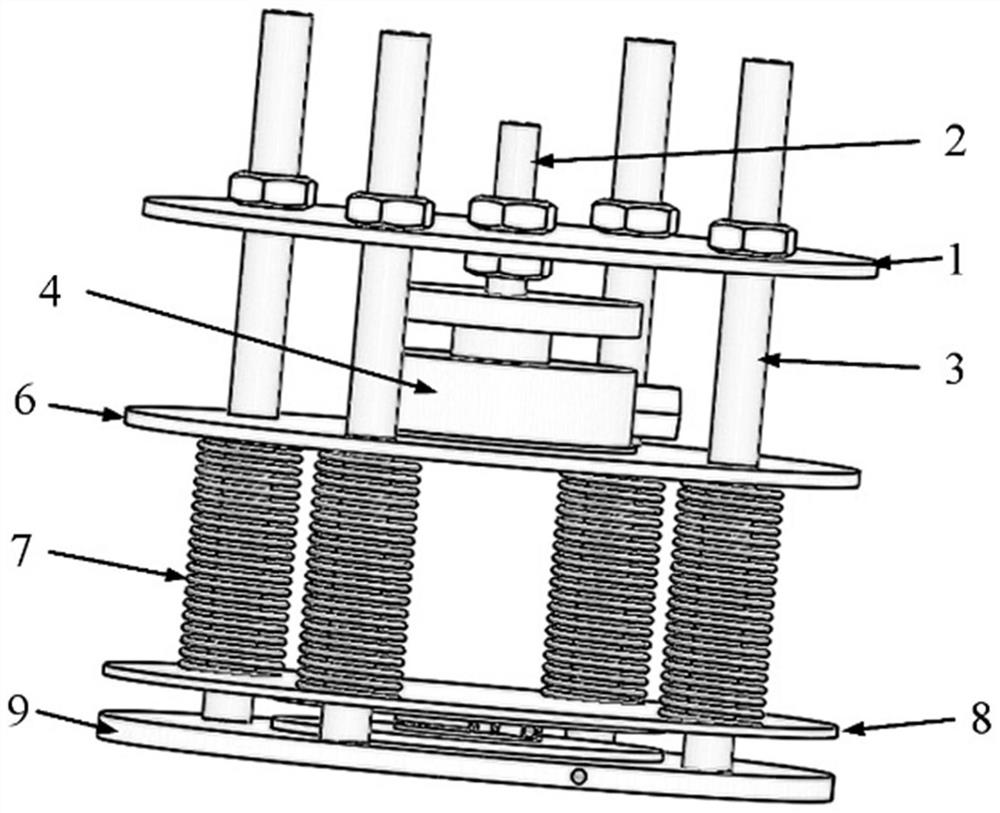

Device and method for testing dielectric properties of solid insulating material interface

A technology of solid insulating materials and dielectric properties, applied in the direction of dielectric property measurement, measuring devices, testing dielectric strength, etc., can solve the problems of large cake-shaped materials, large test devices, uneven electric field distribution, etc., to achieve Good insulation and shielding effect, simple test method, stable and adjustable temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

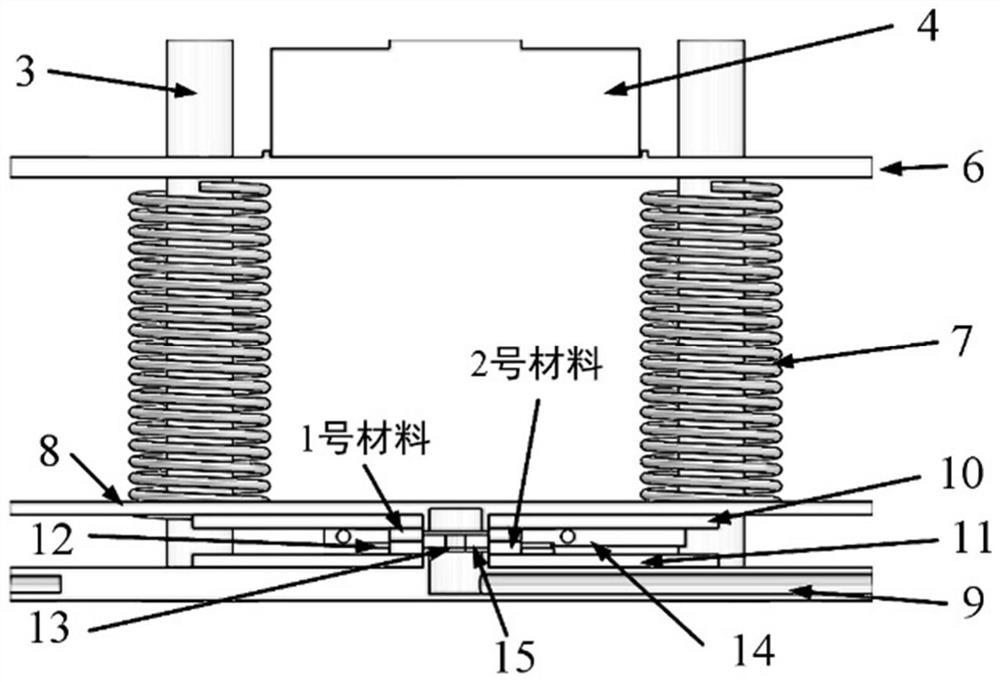

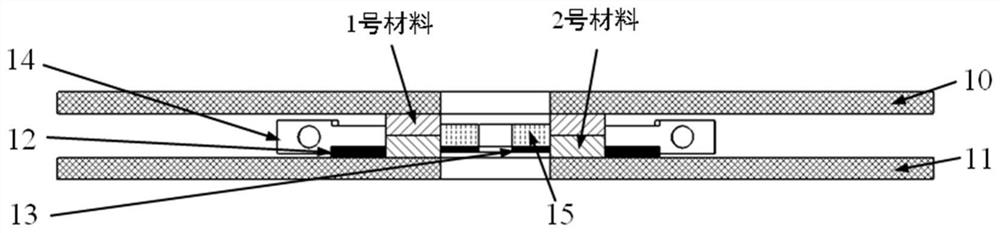

[0054] Example 1, interface conductivity test, comprising the following steps:

[0055] Step 1: Prepare the sample.

[0056] Samples No. 1 and No. 2 were prepared from cross-linked polyethylene (XLPE). Samples No. 1 and No. 2 were circular rings of the same size, with an inner diameter of 10 mm, an outer diameter of 14 mm, and a thickness of 3 mm. Purpose Sandpaper is used to polish the surface of materials, and the interface is formed by the contact of two materials.

[0057] Step 2: According to the geometric structure of the material interface, calculate the material interface area, the formula is as follows:

[0058]

[0059] In the formula, π is the circumference ratio, R 2 is the outer radius of the ring material to be tested, R 1 is the inner radius of the ring material to be tested. Material interface area is 0.75cm 2 .

[0060] Step 3: Select 1MPa as the test pressure of the material interface, and calculate the pressure exerted by the pressure control device...

example 2

[0081] Example 2, interface partial discharge test, including the following steps:

[0082] Step 1: Prepare the sample.

[0083] Samples No. 1 and No. 2 were prepared from cross-linked polyethylene (XLPE). Samples No. 1 and No. 2 were circular rings of the same size, with an inner diameter of 10 mm, an outer diameter of 14 mm, and a thickness of 3 mm. Purpose Sandpaper is used to polish the surface of materials, and the interface is formed by the contact of two materials.

[0084] Step 2: According to the geometric structure of the material interface, calculate the material interface area, the formula is as follows:

[0085]

[0086] In the formula, π is the circumference ratio, R 2 is the outer radius of the ring material to be tested, R 1 is the inner radius of the ring material to be tested. Material interface area is 0.75cm 2 .

[0087] Step 3: Select 1MPa as the test pressure of the material interface, and calculate the pressure exerted by the pressure control de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com