Silicon oxide composite negative electrode material and preparation method thereof, and lithium ion battery

A silicon oxide and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems affecting the cycle performance of silicon oxide-based silicon carbon negative electrode materials, low SiO2 conductivity, ionic conductivity, and distribution uniformity. Inability to strictly control and other problems to achieve the effect of alleviating electronic contact inactivation, improving cycle performance, and improving kinetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

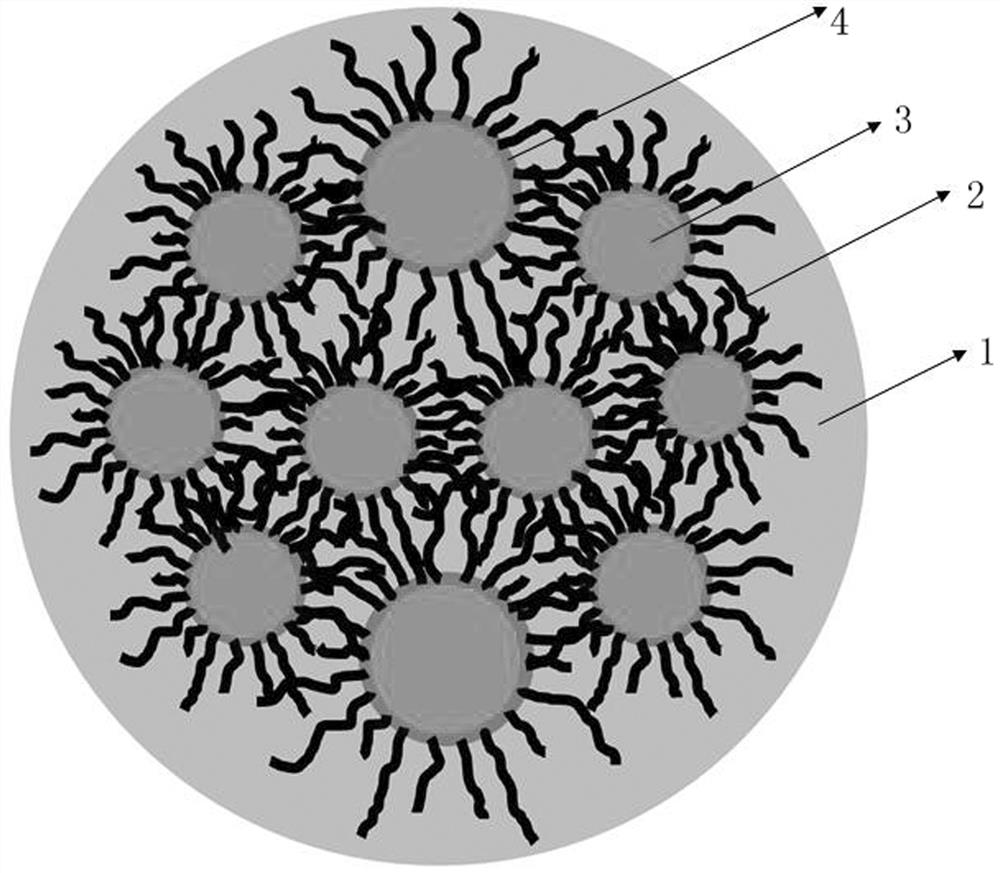

[0033] In a first aspect, the present invention provides a method for preparing a silicon oxide composite negative electrode material, comprising the following steps:

[0034] S1. provide silicon oxide powder, and the silicon oxide powder is a silicon oxide powder without disproportionation;

[0035] S2. carbon coating is performed on the silicon oxide powder to obtain a first precursor;

[0036] S3. growing carbon nanofibers in situ on the surface of the first precursor to obtain a second precursor;

[0037] S4. Perform secondary granulation on the second precursor to obtain the silicon oxide composite negative electrode material.

[0038] Wherein, in step S1, the preparation method of the silicon oxide powder is as follows: after the silicon powder and the silicon dioxide powder are mixed uniformly, in an inert atmosphere or a vacuum environment, heating to generate silicon monoxide gas, and cooling and precipitation to obtain Silicon oxide block; crushing and pulverizing ...

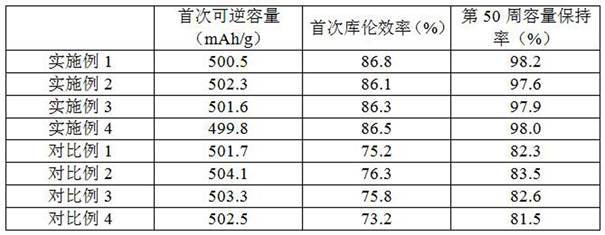

Embodiment 1

[0066] The silicon oxide composite negative electrode material, the preparation method steps are as follows:

[0067] S1. provide silicon oxide powder, and the silicon oxide powder is a silicon oxide powder without disproportionation treatment; the preparation method of the silicon oxide powder is: mixing silicon powder and silicon dioxide powder uniformly Then, in an inert atmosphere or a vacuum environment, it is heated to 1400° C. to generate silicon monoxide gas, which is cooled and precipitated on a deposition plate to obtain a silicon oxide block; the silicon oxide block is crushed by a jaw crusher. Particles with an average particle size of 0.5-8mm are then pulverized and pulverized by air flow to obtain silicon oxide powder with a particle size D50 of 0.1-1 μm; wherein, the molar ratio of the silicon powder and the silicon dioxide powder is 0.5:0.5; The particle size D50 of the silicon powder is 1-100 μm, and the particle size D50 of the silicon dioxide powder is 0.01-...

Embodiment 2

[0072] The silicon oxide composite negative electrode material, the preparation method steps are as follows:

[0073] S1. provide silicon oxide powder, and the silicon oxide powder is a silicon oxide powder without disproportionation treatment; the preparation method of the silicon oxide powder is: mixing silicon powder and silicon dioxide powder uniformly Then, in an inert atmosphere or a vacuum environment, it is heated to 900 ° C to generate silicon monoxide gas, which is cooled and precipitated on a deposition plate to obtain a silicon oxide block; the silicon oxide block is crushed by a jaw crusher. Particles with an average particle size of 0.5-8mm are then pulverized and pulverized by air flow to obtain silicon oxide powder with a particle size D50 of 0.1-1 μm; wherein, the molar ratio of the silicon powder and the silicon dioxide powder is 0.6:0.4; The particle size D50 of the silicon powder is 1-100 μm, and the particle size D50 of the silicon dioxide powder is 0.01-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com