Preparation method of biomass carbon lithium ion battery negative electrode material

A lithium-ion battery, biomass carbon technology, applied in the field of electrochemical power supply, can solve the problems of unsatisfactory cycle performance, low conductivity, poor electrochemical reaction kinetics, etc., and achieve good cycle stability and abundant biomass resources. , repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

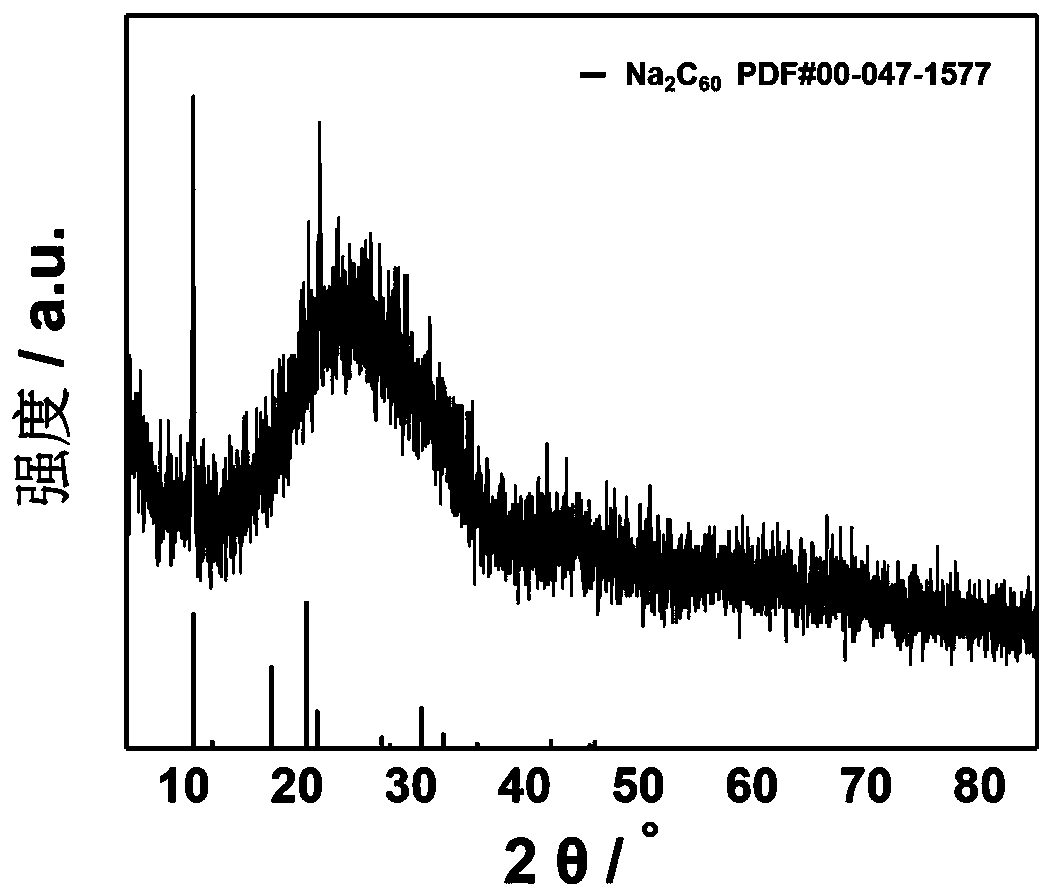

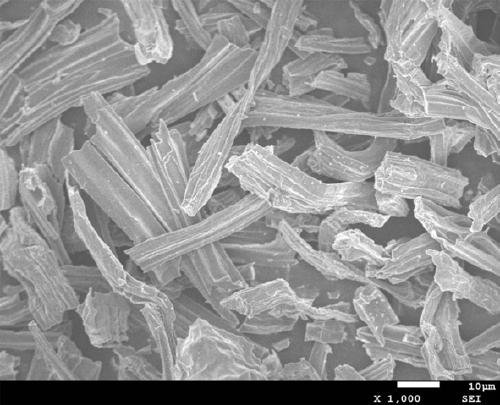

[0037] Cattail ears (such as figure 1 ) in sodium hydroxide solution for 2 hours, then cleaned with deionized water, and then transferred to a blast drying oven at 80°C for drying; the dried cattail ears were placed in N 2 In the environment, calcining at 500°C for 5h at a heating rate of 3°C / min to obtain black biomass carbon. The prepared samples were analyzed by XRD patterns as follows: figure 2 As shown, the obtained diffraction peaks are similar to Na 2 C 60 (PDF#00-047-1577) Correspondingly, there is a broad diffraction peak around 25°, corresponding to amorphous C. NaOH appeared in XRD due to the use of NaOH in the treatment of cattail ears 2 C 60 peak. SEM of the prepared samples as image 3 As shown, after sintering, the cattail ears are in the shape of micron bands, and the surface is wrinkled, which increases the specific surface area of the material. This special morphology makes the battery have a high lithium storage capacity and good cycle stability. ...

Embodiment 2

[0040] Cattail ears (such as figure 1 ) was cleaned with deionized water, and then transferred to a blast drying oven at 80°C for drying; the dried cattail ears were placed in N 2 In the environment, calcining at 600°C for 5h at a heating rate of 3°C / min to obtain black biomass carbon.

[0041] The material obtained in Example 2 was made into a battery according to the method in Example 1. Such as Figure 5 As shown, the first charge and discharge specific capacities are 335.2 and 564.3mAh g respectively -1 , the charge and discharge capacities are 251.6 and 253.7mAh g after 50 cycles -1 , poor electrochemical performance.

Embodiment 3

[0043] Cattail ears (such as figure 1 ) in sodium hydroxide solution for 2 hours, then cleaned with deionized water, and then transferred to a blast drying oven at 80°C for drying; the dried cattail ears were placed in N 2 In the environment, calcining at 600°C for 5h at a heating rate of 3°C / min to obtain black biomass carbon.

[0044] The material obtained in Example 2 was made into a battery according to the method in Example 1. Such as Image 6 As shown, the first charge and discharge specific capacities are 508.0 and 916.9mAh g respectively -1 , there is an obvious charge and discharge platform, and the charge and discharge capacities are 315.9 and 378.0mAh g after 50 cycles -1 , showing good electrochemical performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com