A porous transition metal cobalt electrode supported by foamed nickel, its preparation method and its application in electrocatalytic oxidation of sodium borohydride

A technology of transition metal and nickel foam, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor electrode conductivity and unstable structure, and achieve the effects of reducing electrode cost, stable electrode structure, and high catalyst utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

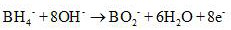

[0025]The process of preparing a porous transition metal cobalt electrode supported by foamed nickel:

[0026](1) Take a piece of foam (1 cm × 1 cm) as a catalyst carrier;

[0027](2) Place foam as a working electrode, placed in 50 ml containing 0.10 mol·L-1 COSO4· 7h2O, 0.20mol·L-1 Hide3BO4, 3.43 mol·L-1 C2Hide5OH and 3.35 mmol·L-1In the aqueous solution of tetramethoxysilane, the hydrochloride electrode and the graphite rod are respectively used as the reference electrode and the pair of electrodes, respectively, the deposition time is 15 min, the deposition potential is -2 V, obtaining the CO of foam support SiO2Composite material;

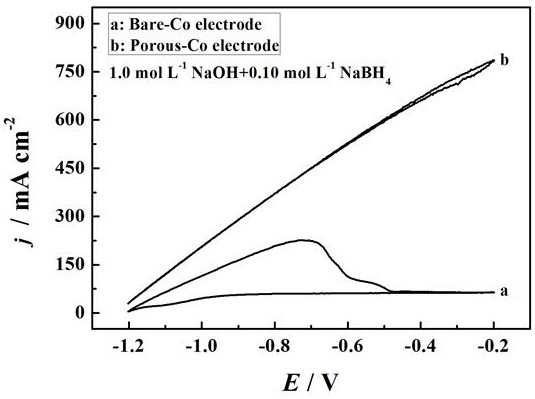

[0028](3) CO-SIO supported by the prepared foam2The composite material is placed in a working electrode and placed in 1.0 mol·L.-1In the NaOH solution, the silver chloride electrode and the graphite rod are respectively used as the reference electrode and the counter electrode, and the circulation voltammetry is used (process parameters: the scan range is -0....

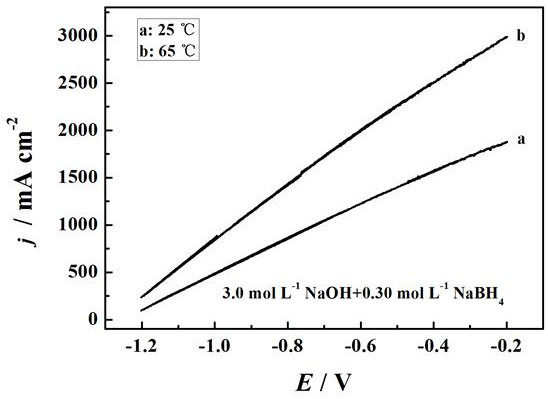

Embodiment 2

[0032]The process of preparing a porous transition metal cobalt electrode supported by foamed nickel:

[0033](1) Take a piece of foam (1 cm × 1 cm) as a catalyst carrier;

[0034](2) Place foam as a working electrode, placed in 50 ml containing 0.10 mol·L-1 COSO4· 7h2O, 0.20mol·L-1 Hide3BO4, 3.43 mol·L-1 C2Hide5OH and 3.35 mmol·L-1In the aqueous solution of tetramethoxysilane, the hydrochloride electrode and the graphite rod are respectively used as the reference electrode and the pair of electrodes, respectively, the deposition time is 15 min, the deposition potential is -2 V, obtaining the CO of foam support SiO2Composite material;

[0035](3) CO-SIO supported by the prepared foam2The composite material is placed in a working electrode and placed in 1.0 mol·L.-1In the NaOH solution, the silver chloride electrode and the graphite rod are respectively used as the reference electrode and the counter electrode, and the circulation voltammetry is used (process parameters: the scan range is -0....

Embodiment 3

[0038]The process of preparing a porous transition metal cobalt electrode supported by foamed nickel:

[0039](1) Take a piece of foam (1 cm × 1 cm) as a catalyst carrier;

[0040](2) Place foam as a working electrode, placed in 50 ml containing 0.10 mol·L-1 COSO4· 7h2O, 0.20mol·L-1 Hide3BO4, 3.43 mol·L-1 C2Hide5OH and 3.35 mmol·L-1In the aqueous solution of tetramethoxysilane, the hydrochloride electrode and the graphite rod are respectively used as the reference electrode and the pair of electrodes, respectively, the deposition time is 15 min, the deposition potential is -2 V, obtaining the CO of foam support SiO2Composite material;

[0041](3) CO-SIO supported by the prepared foam2The composite material is placed in a working electrode and placed in 1.0 mol·L.-1In the NaOH solution, the silver chloride electrode and the graphite rod are respectively used as the reference electrode and the counter electrode, and the circulation voltammetry is used (process parameters: the scan range is -0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com