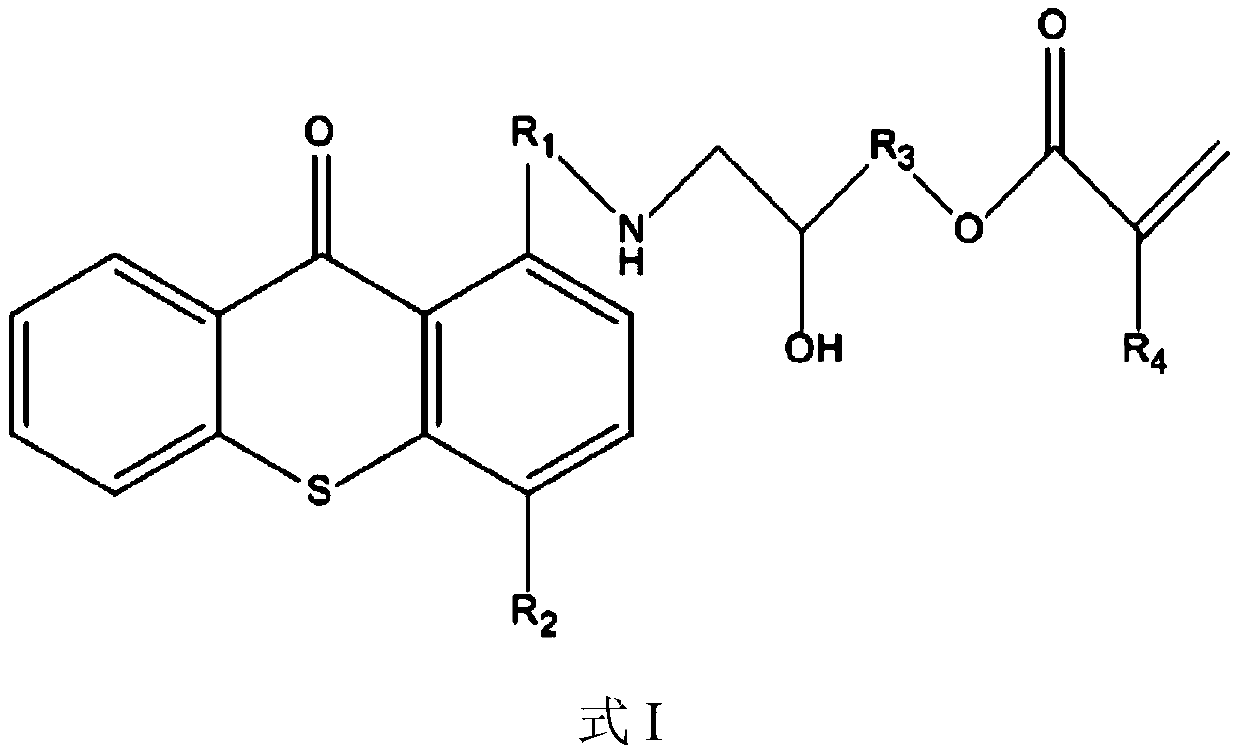

Polymerizable photoinitiator, preparation method and applications thereof

A polymerization photoinitiator and reaction technology, which is applied in the field of photopolymerization, can solve the problems of macromolecular initiator movement ability and system compatibility, and the influence of dosage on product performance, and achieve simple and efficient preparation methods, high energy transfer efficiency, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

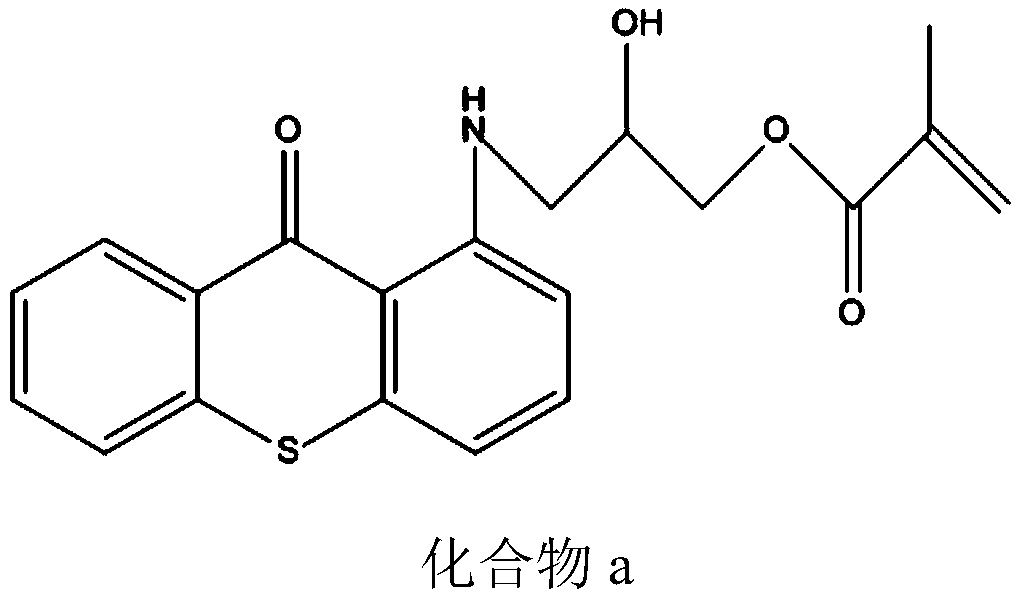

Embodiment 1

[0035] In this embodiment, the preparation method of compound a is provided:

[0036]

[0037] The preparation method comprises the following steps:

[0038] (1) Slowly add 0.01mol thiosalicylic acid to 0.09mol concentrated sulfuric acid, stir well, then add 0.05mol aniline in batches, stir mechanically, react at room temperature for 1 hour, raise the temperature to 80°C for 3 hours, pour the reactant into boiling water , boiled for 15 minutes, filtered with suction, and recrystallized with a mixed solution of ethanol and water (the volume ratio of ethanol and water was 4:1) to obtain the product.

[0039] (2) Add 0.0078 mol of the above product into 50 ml of tetrahydrofuran for dissolution, then add 0.0234 mol of glycidyl methacrylate, add 0.001 mol of anhydrous potassium carbonate to provide alkaline conditions, react at 70 ° C for 5 hours, and remove the solvent by rotary evaporation to obtain target product. The appearance of the hydroxyl peak of the product was obser...

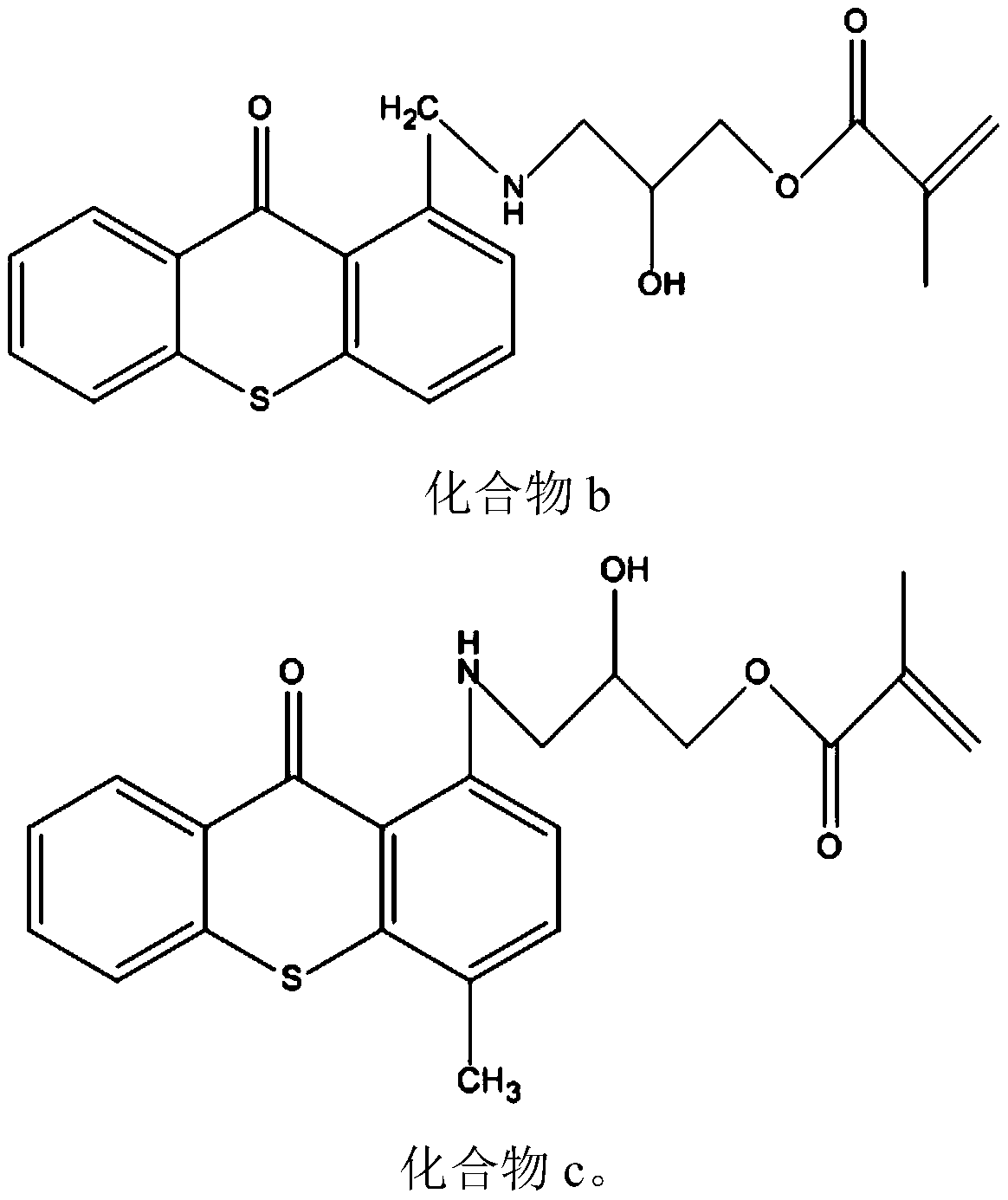

Embodiment 2

[0041] In this example, the preparation method of compound b is provided:

[0042]

[0043] The preparation method comprises the following steps:

[0044](1) Slowly add 0.01mol thiosalicylic acid into 0.10mol concentrated sulfuric acid, stir well, then add 0.06mol benzylamine in batches, stir mechanically, react at room temperature for 1h, raise the temperature to 80°C for 3h, pour the reactant Pour into boiling water, boil for 15 minutes, filter with suction, and recrystallize with a mixed solution of ethanol and water (the volume ratio of ethanol and water is 4:1) to obtain the product.

[0045] (2) Add 0.0082 mol of the above product into 50 ml of tetrahydrofuran for dissolution, then add 0.0164 mol of glycidyl methacrylate, add 0.001 mol of anhydrous potassium carbonate to provide alkaline conditions, react at 70 ° C for 5 hours, and remove the solvent by rotary evaporation to obtain target product. The appearance of the hydroxyl peak of the product was observed by in...

Embodiment 3

[0047] In this embodiment, the preparation method of compound c is provided:

[0048]

[0049] The preparation method comprises the following steps:

[0050] (1) Slowly add 0.01mol thiosalicylic acid into 0.09mol concentrated sulfuric acid, stir well, then add 0.04mol p-benzylamine in batches, stir mechanically, react at room temperature for 1 hour, heat up to 80°C for 3 hours, and dissolve the reactant Pour into boiling water, boil for 15 minutes, filter with suction, and recrystallize with a mixed solution of ethanol and water (the volume ratio of ethanol and water is 4:1) to obtain the product.

[0051] (2) Add 0.0081 mol of the above-mentioned product to 50 ml of tetrahydrofuran for dissolution, then add 0.0162 mol of glycidyl methacrylate, add 0.001 mol of anhydrous potassium carbonate to provide alkaline conditions, react at 70 ° C for 5 hours, and remove the solvent by rotary evaporation to obtain target product. The appearance of the hydroxyl peak of the product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com