Preparation method and application of self-emulsifying accelerant for epoxy colored sand

A technology of epoxy colored sand and self-emulsification, which is applied in the direction of adhesive additives, polymer adhesive additives, etc., and can solve the problems of inability to meet the requirements of light-colored products, poor fluidity, and deep color products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of self-emulsifying accelerator is as follows:

[0023] Add 0.01mol% of dibutyltin dilaurate to IPDI, heat to 35℃, add polyethylene glycol monomethyl ether dropwise to control the molar ratio of polyethylene glycol monomethyl ether to IPDI to 1:1.2, use two The n-butylamine titration method is used to determine the -NCO content. When the NCO% is basically stable after the reaction, vacuum distillation is performed to remove the excess IPDI to obtain the intermediate product;

[0024] Heat the bisphenol A epoxy to 80°C, add dodecylamine dropwise, control the molar ratio of dodecylamine to bisphenol A epoxy to 1:2.2, after the addition is completed, heat up to 85°C, react for 4 hours, and add the intermediate The product is such that the molar ratio of dodecylamine to intermediate product is 1:1.95. It reacts to NCO%<0.1%, and is prepared from emulsification accelerator.

Embodiment 2

[0026] The molar ratio of dodecylamine to intermediate product is 1:1.5.

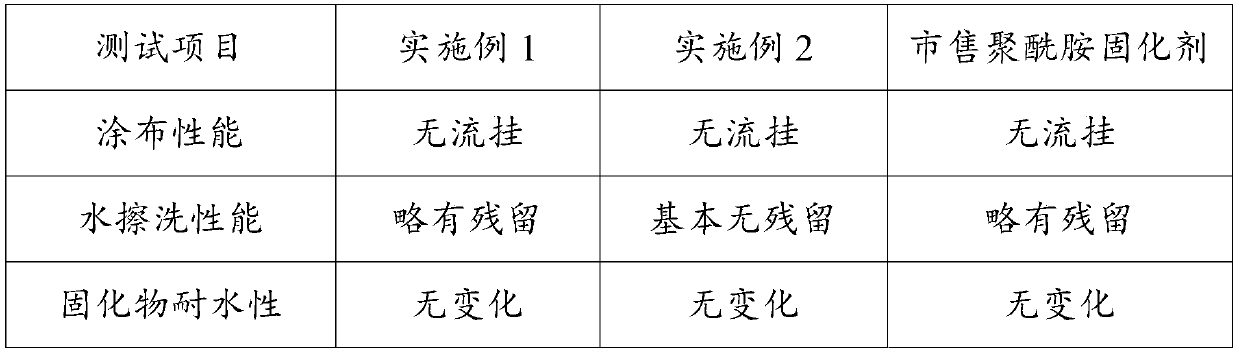

[0027] The accelerators of Example 1 and Example 2 were dispersed in deionized water, and the characteristics of the aqueous solution and the dispersion stability after standing for 24 hours were observed. The results are shown in Table 1.

[0028] Table 1

[0029] Test items Example 1 Example 2 Characteristics of aqueous solution Translucent emulsion White emulsion Dispersion stability stable Slight delamination

[0030] It can be seen from the above results that the accelerator of Example 1 has excellent water solubility and emulsification properties, and good dispersion stability. From the comparison between Example 1 and Example 2, it can be seen that increasing the amount of intermediate product, that is, increasing the content of hydrophilic segments in the accelerator, is beneficial to the improvement of self-emulsification performance.

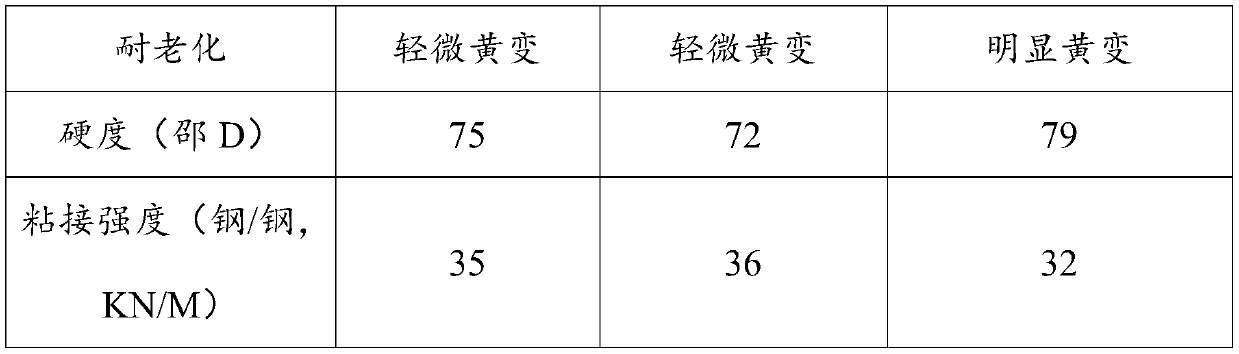

[0031] A waterborne epoxy resin with 100% solid content and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com