a namno 2 @ni 2 o 3 Composite material and its preparation method and application in sodium ion battery

A composite material and precursor material technology, applied in NaMnO2@Ni2O3 composite material and its preparation, the application field of sodium ion battery, can solve the problems affecting the electrochemical performance of the battery, structural instability, etc., to improve the electrochemical performance, The effect of improving production efficiency and product quality and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a NaMnO 2 @Ni 2 o 3 A method for preparing a composite material, comprising the steps of:

[0024] (1) Add 0.4102g of sodium acetate, 1.25g of manganese acetate, 0.040g of polyethylene glycol and 0.040g of glucose into water, ultrasonicate for half an hour to obtain a homogeneous mixed solution, and then feed the mixed solution at a feed rate of 2L / h, at the inlet Spray drying at a temperature of 220°C and an outlet temperature of 100°C to obtain precursor materials;

[0025] (2) Mix the precursor material with nickel acetate at a mass ratio of 5:1, add water and then ball mill it downward at a speed of 400rpm for 5 hours. Calcined at 500 °C for 3 h under nitrogen atmosphere to obtain NaMnO 2 @Ni 2 o 3 composite material.

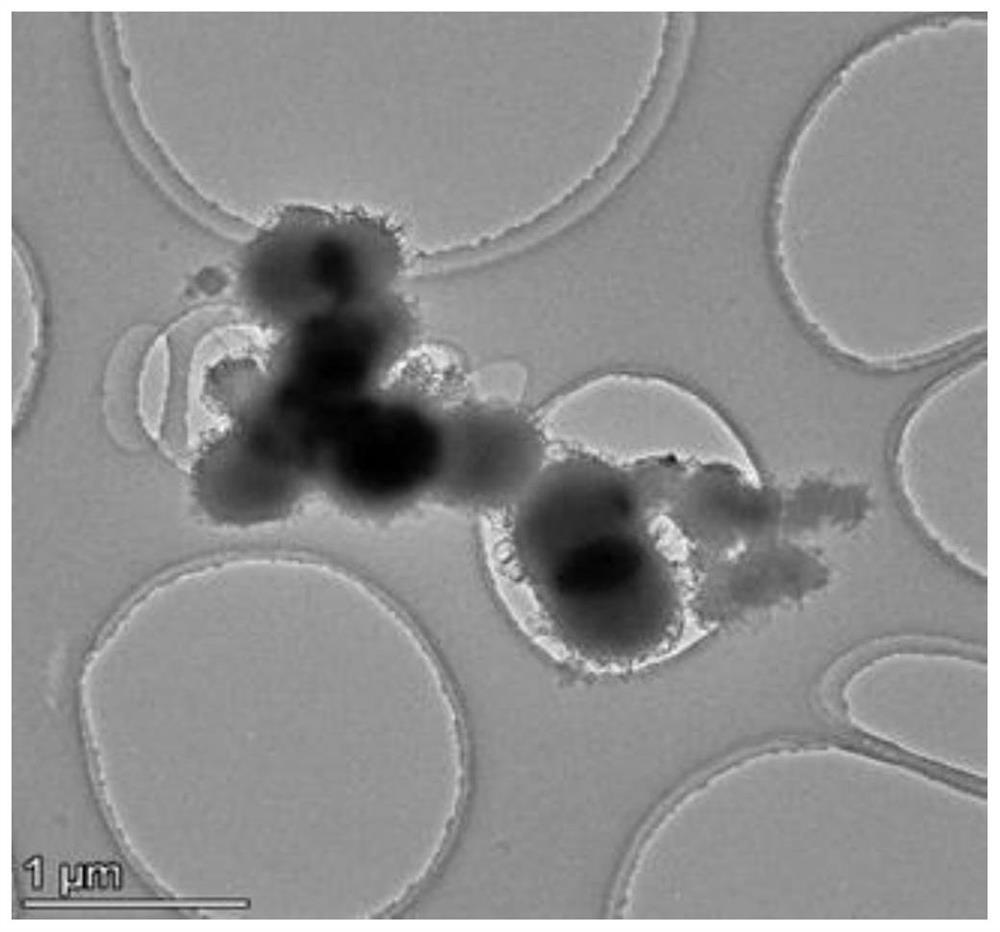

[0026] To the NaMnO that present embodiment makes 2 @Ni 2 o 3 Composites observed by transmission electron microscopy. TEM such as figure 1 shown, from figure 1 It can be seen that the prepared NaMnO 2 @Ni 2 o 3 The particle size of t...

Embodiment 2

[0028] a NaMnO 2 @Ni 2 o 3 A method for preparing a composite material, comprising the steps of:

[0029] (1) Add 0.4512g sodium nitrate, 1.25g manganese acetate, 0.061g polyethylene glycol and 0.071g glucose into water, and ultrasonicate for half an hour to obtain a homogeneous mixed solution, and then put the mixed solution at a feed rate of 3L / h, at the inlet Spray drying at a temperature of 230°C and an outlet temperature of 110°C to obtain precursor materials;

[0030] (2) Mix the precursor material with nickel hydroxide at a mass ratio of 6:1, add water and ethanol (the mass ratio of water and ethanol is 1:1), and then ball mill it downward at a speed of 500 rpm for 2 hours. ℃ for 6 hours, and then placed in a tube furnace for calcination at 600 ℃ for 2 hours under a nitrogen atmosphere to obtain NaMnO 2 @Ni2 o 3 composite material.

Embodiment 3

[0032] a NaMnO 2 @Ni 2 o 3 A method for preparing a composite material, comprising the steps of:

[0033] (1) Add 0.5332g sodium chloride, 1.46g manganese sulfate, 0.005g polyvinyl alcohol and 0.006 sucrose into water, and ultrasonically half an hour to obtain a homogeneous mixed solution, which is then fed at a feed rate of 2L / h, imported Spray drying at a temperature of 200°C and an outlet temperature of 90°C to obtain precursor materials;

[0034] (2) Mix the precursor material with nickel chloride at a mass ratio of 5:1, add water and ethanol (the mass ratio of water and ethanol is 1:1), and then ball mill it downward at a speed of 400 rpm for 5 hours. ℃ for 8 hours, and then placed in a tube furnace for calcination at 400 ℃ for 9 hours under a nitrogen atmosphere to obtain NaMnO 2 @Ni 2 o 3 composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com