Hydro-cracking method of catalytic diesel oil

A technology for hydrocracking and catalyzing diesel oil, which is applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of uncontrollable refining reactor and cracking reactor, etc., to avoid temperature mismatch, sulfur and nitrogen content, etc. Low, high octane effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

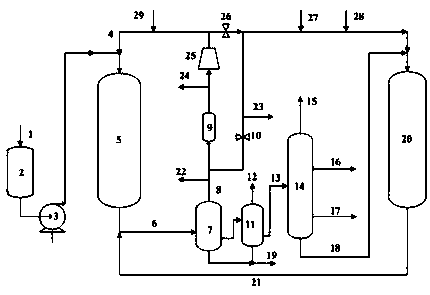

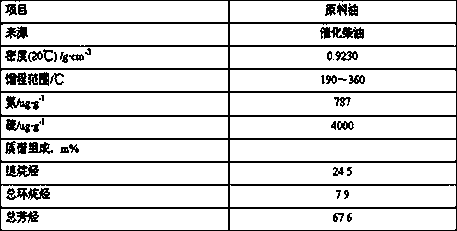

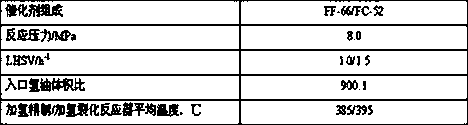

[0036] Catalyzed diesel oil is used as raw material, and the industrial hydrofinishing agent FF-66 and hydrocracking agent FC-52 system are selected. figure 1 The operating process and implementation process conditions are as shown in Table 3. In the initial stage of device operation, cyclohexylamine is injected into the raw material tank to control the concentration of acidic water at 1000-8000 ppm, and the concentration of hydrogen sulfide at the inlet of the circulating hydrogen compressor is controlled at 20-150 ppm. After the product is qualified, close the side line control valve 10 of the circulating hydrogen desulfurization tower, open the control valve 26, and control the circulating hydrogen concentration at the outlet of the circulating hydrogen desulfurization tower at 500-1000 ppm. At the end of the operation of the device, open the control valve 10 and close the control valve 26 to control the concentration of hydrogen sulfide at point 23 between 2000-5000 ppm an...

Embodiment 2

[0038] Catalyzed diesel oil is used as raw material, and the industrial hydrofinishing agent FF-66 and hydrocracking agent FC-52 system are selected. figure 1 The operating process and implementation process conditions are as shown in Table 3. In the initial stage of device operation, n-butylamine is injected into the raw material tank to control the concentration of acidic water at 1000-8000 ppm, and the concentration of hydrogen sulfide at the inlet of the circulating hydrogen compressor is controlled at 20-150 ppm. After the product is qualified, close the side line control valve 10 of the circulating hydrogen desulfurization tower, open the control valve 26, and control the circulating hydrogen concentration at the outlet of the circulating hydrogen desulfurization tower at 500-1000 ppm. At the end of the operation of the device, open the control valve 10, close the control valve 26, and control the concentration of hydrogen sulfide at point 23 to be between 2000-5000 ppm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com