Leaching system and method for recovering valuable metals from waste lithium cobaltate batteries

A technology of valuable metals and lithium cobaltate, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as environmental secondary pollution, a large amount of acid waste gas and acid waste liquid, and achieve low equipment cost, Simple equipment, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of leaching method that reclaims the valuable metal of waste lithium cobalt oxide battery comprises the following steps:

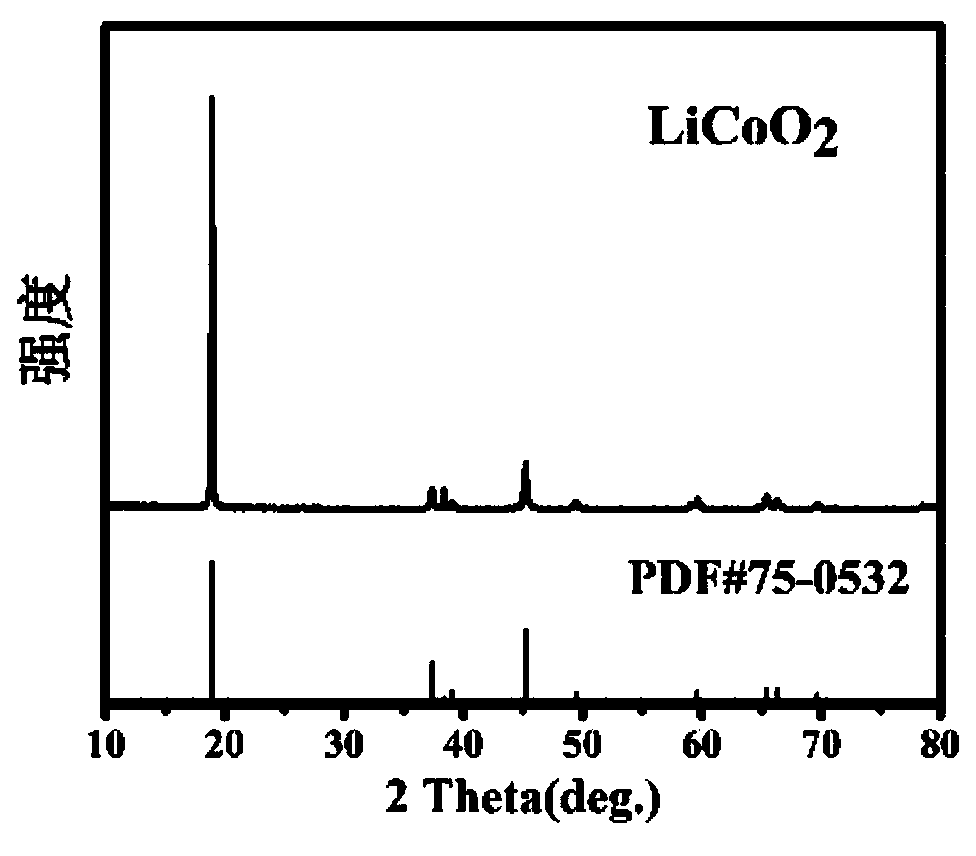

[0031] (1) After dismantling and crushing of waste lithium cobalt oxide batteries, the positive electrode material powder is separated. The positive electrode powder contains 7.39% Li and 60.23% Co, mainly in the form of lithium cobalt oxide (see figure 1 );

[0032] (2) Prepare a leaching system for recovering valuable metals from waste lithium cobaltate batteries, that is, a mixed aqueous solution of ammonia-sodium sulfite-ammonium chloride, in which the concentration of ammonia is 4mol / L, the concentration of sodium sulfite is 0.5mol / L, and the concentration of ammonium chloride The concentration is 1.5mol / L;

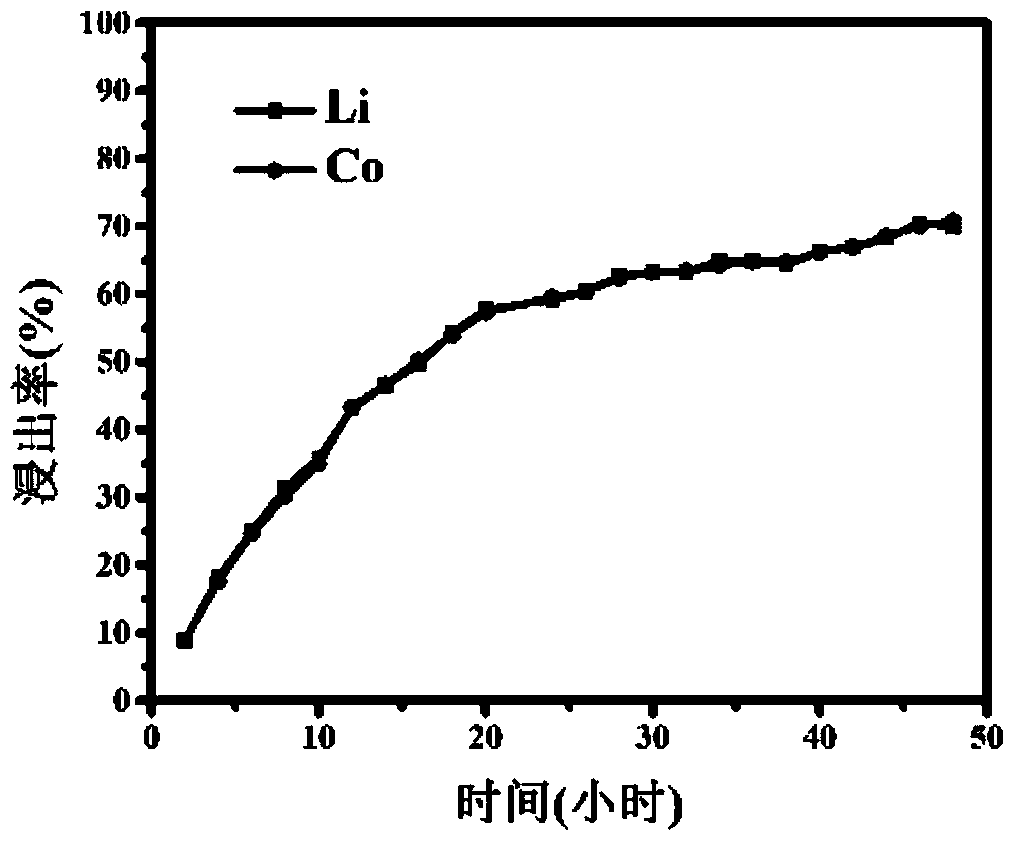

[0033] (3) Take 300mL of the leaching system of step (2) and add it to a 500mL three-neck flask, install a condensation device, then heat to 80°C, add 3g of the positive electrode powder obtained in step (1), and carry out the lea...

Embodiment 2

[0036] A kind of leaching method that reclaims the valuable metal of waste lithium cobalt oxide battery comprises the following steps:

[0037] (1) After dismantling and crushing of waste lithium cobalt oxide batteries, the positive electrode material powder is separated;

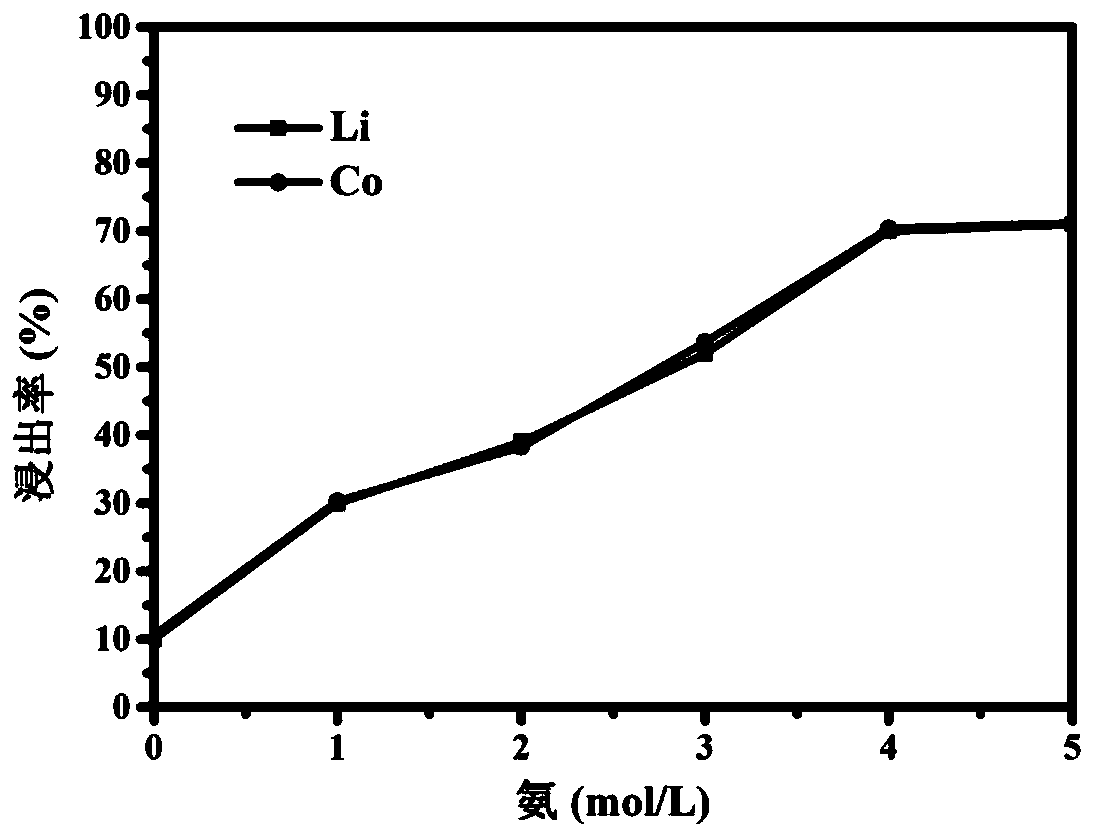

[0038] (2) Prepare a leaching system for recovering valuable metals from waste lithium cobaltate batteries with different ammonia concentrations, that is, a mixed aqueous solution of ammonia-sodium sulfite-ammonium chloride, where the ammonia concentrations are 0, 1, 2, 3, 4 and 5mol respectively / L, the concentration of sodium sulfite is 0.5mol / L, and the concentration of ammonium chloride is 1.5mol / L.

[0039] (3) Take 300mL of leaching systems with different ammonia concentrations in step (2) and add them to a 500mL three-neck flask, install a condensation device, then heat to 80°C, add 3g of the positive electrode powder obtained in step (1) respectively, and stir at 500rpm magnetic force , carry out t...

Embodiment 3

[0042] A kind of leaching method that reclaims the valuable metal of waste lithium cobalt oxide battery comprises the following steps:

[0043] (1) After dismantling and crushing of waste lithium cobalt oxide batteries, separate the cathode material powder;

[0044] (2) Prepare a leaching system for recovering valuable metals from waste lithium cobaltate batteries with different concentrations of sodium sulfite, that is, a mixed aqueous solution of ammonia-sodium sulfite-ammonium chloride, in which the concentration of ammonia is 4mol / L, and the concentration of sodium sulfite is 0 and 0.1 respectively , 0.2, 0.4, 0.5, 1.0, 2.0, 3.0mol / L, the concentration of ammonium chloride is 1.5mol / L.

[0045] (3) Take 300mL of the leaching system with different concentrations of sulfurous acid in step (2) and add them to a 500mL three-neck flask, install a condensation device, then heat to 80°C, add 3g of the positive electrode powder obtained in step (1) respectively. Under stirring, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com