Method for eluting residual ammonium salt in closed mine field of weathering crust elution-deposited rare earth ore

A weathering crust elution type, rare earth ore technology, applied in the field of mine pollution control and soil remediation, can solve the problems of reducing ammonium salt residues, ammonia nitrogen pollution, etc., and achieve the effect of solving the problem of ammonia nitrogen pollution and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

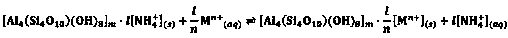

Method used

Image

Examples

Embodiment 1

[0025] A weathered crust elution type rare earth mine in Longnan County, Ganzhou City, Jiangxi Province was selected as an experimental study for the in-situ leaching of closed mine samples. The residual ammonium content of the closed mine samples was 1.86 mg / g (calculated as N). A method for leaching residual ammonium salts in a weathered crust leaching type rare earth mine closure field adopts a column leaching simulation actual process to leaching residual ammonium salts, comprising the following steps:

[0026] 1) Under the simulated actual process conditions of column leaching weathering crust leaching type rare earth mine tailings, use hydrochloric acid to adjust the pH value of the sodium chloride solution to 5.0, and inject sodium chloride into the closure field of weathering crust leaching type rare earth ore solution, the concentration of the sodium chloride solution is 0.04mol / L, and it is removed by leaching, and the injection flow rate is 0.4 mL / min to obtain the r...

Embodiment 2

[0030] A weathered crust elution type rare earth mine in Longnan County, Ganzhou City, Jiangxi Province was selected as an experimental study for the in-situ leaching of closed mine samples. The residual ammonium content of the closed mine samples was 1.86 mg / g (calculated as N). A method for leaching residual ammonium salts in a weathered crust leaching type rare earth mine closure field adopts a column leaching simulation actual process to leaching residual ammonium salts, comprising the following steps:

[0031] 1) Under the simulated actual process conditions of column leaching weathering crust leaching-type rare earth ore tailings, adjust the pH value of calcium nitrate solution to 7.0 with sulfuric acid, and inject calcium nitrate solution into the closure field of weathering crust leaching-type rare earth ore, The concentration of calcium nitrate solution is 0.30mol / L, carry out elution and remove, and injection flow rate is 0.8 mL / min, obtain residual ammonium salt elue...

Embodiment 3

[0035] A weathered crust elution type rare earth mine in Longnan County, Ganzhou City, Jiangxi Province was selected as an experimental study for the in-situ leaching of closed mine samples. The residual ammonium content of the closed mine samples was 1.86 mg / g (calculated as N). A method for leaching residual ammonium salts in a weathered crust leaching type rare earth mine closure field adopts a column leaching simulation actual process to leaching residual ammonium salts, comprising the following steps:

[0036] 1) Under the simulated actual process conditions of column leaching weathering crust leaching type rare earth mine tailings, adjust the pH value of magnesium nitrate solution to 5.5 with nitric acid, and inject magnesium nitrate solution into the closure field of weathering crust leaching type rare earth ore, The concentration of magnesium nitrate solution is 0.1mol / L, carries out elution and removes, and injection flow rate is 0.6 mL / min, obtains residual ammonium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com