Device for circularly cleaning and dissolving chemicals and method for circularly cleaning and dissolving chemicals

A technology of chemicals and cleaning fluids, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems affecting production efficiency, waste of water resources, and increase the difficulty of product debugging, etc., to achieve easy Effects of maintenance, saving resources, and accelerating dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

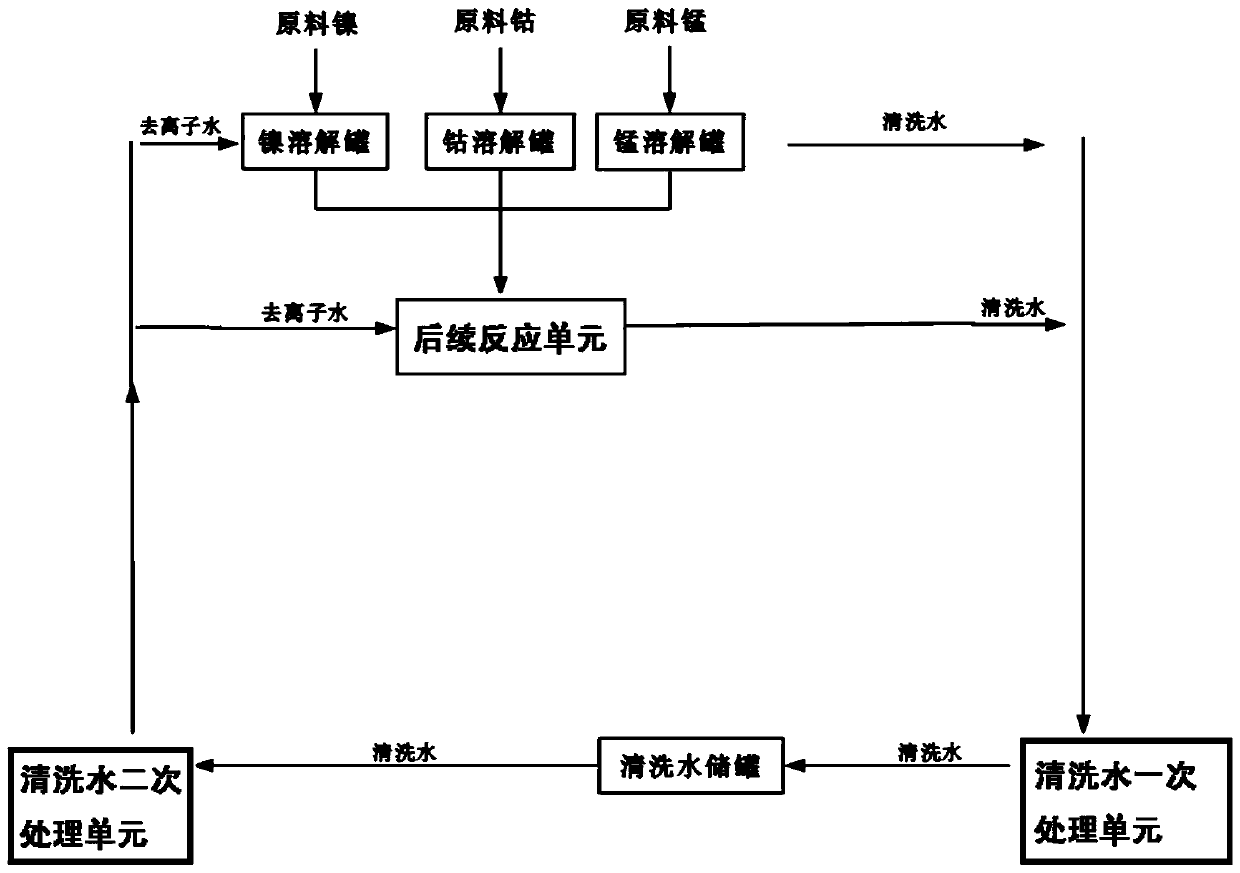

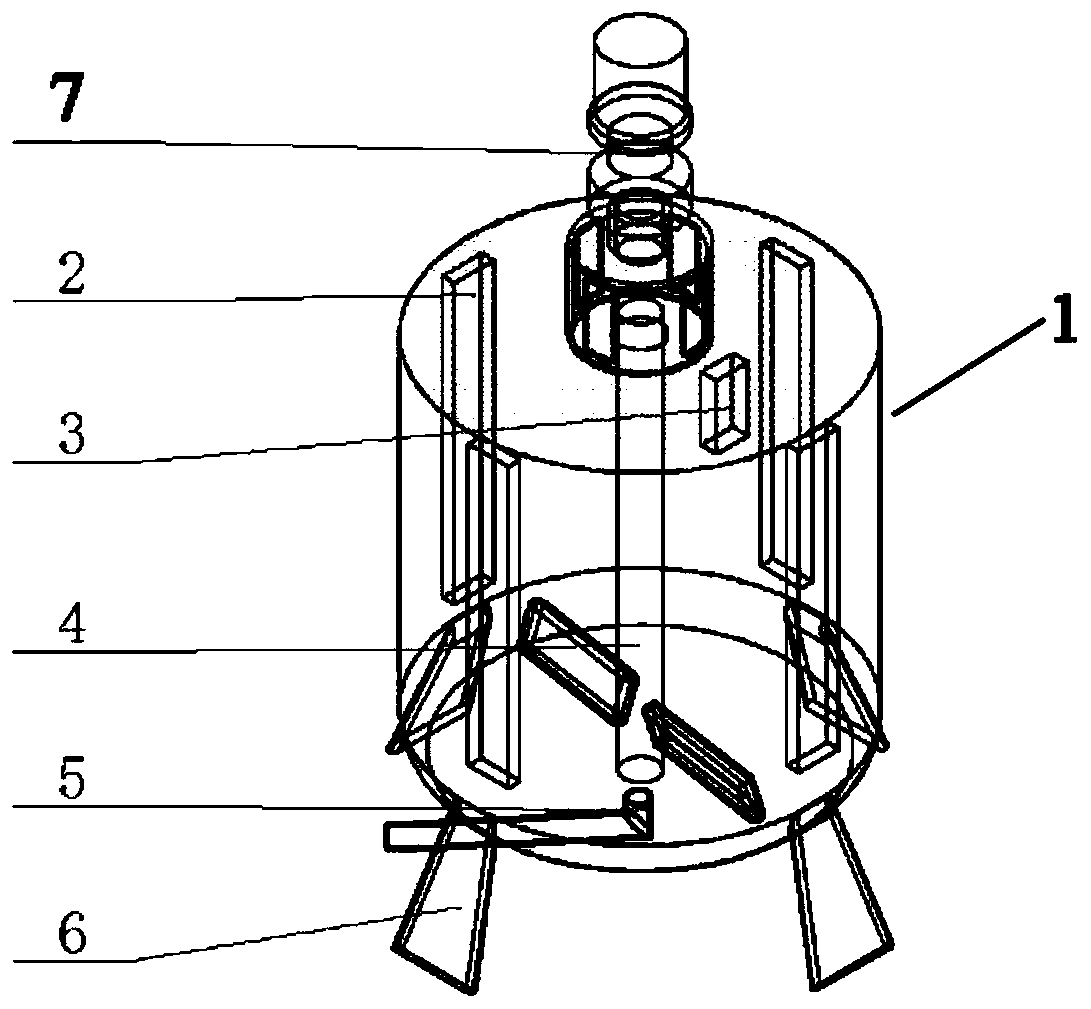

[0064] This embodiment provides a device for circulating cleaning and dissolving chemicals, the schematic diagram of the device is as follows figure 1 shown. The device comprises: a sequentially connected chemical dissolution unit, a cleaning solution primary treatment unit, and a cleaning solution storage unit (i.e. figure 1 The cleaning water storage tank) and the cleaning liquid secondary treatment unit, the cleaning liquid secondary treatment unit is also connected with the chemical dissolution unit, and the chemical dissolution unit includes an ultrasonic dispersion tank.

[0065] The chemical dissolving unit includes three ultrasonic dispersing tanks: a nickel dissolving tank, a cobalt dissolving tank and a manganese dissolving tank. These three ultrasonic dispersing tanks are all connected to the cleaning liquid primary processing unit and the cleaning liquid secondary processing unit at the same time.

[0066] The cleaning liquid primary treatment unit includes a soli...

Embodiment 2

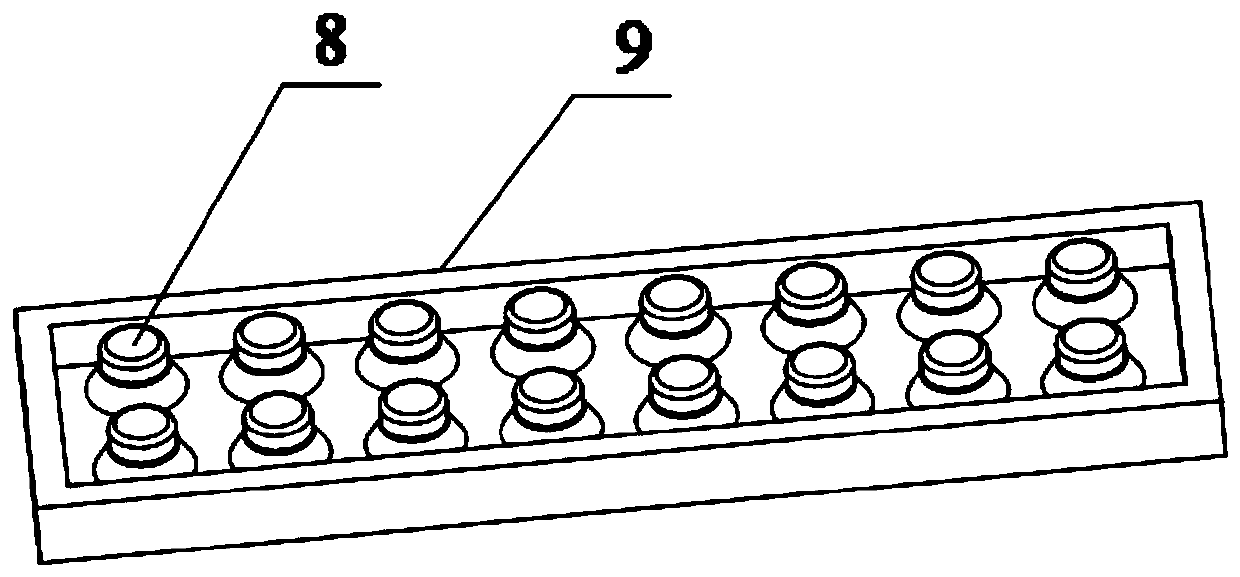

[0078] This embodiment provides a device for circulating cleaning and dissolving chemicals, except that the number of ultrasonic transducer vibrators placed on one side of the vibrating plate shell in the ultrasonic transducer vibrating plate is 14, and the number of vibrators between adjacent ultrasonic transducer vibrating elements is 14. Except that the spacing is 80mm, other aspects are the same as the device for circulating cleaning and dissolving chemicals provided in Example 1.

[0079] This embodiment also provides a method of using the device of this embodiment to perform circular cleaning and dissolve the raw material of the ternary material precursor, the specific method is:

[0080] (1) Pass the deionized water produced by the cleaning liquid secondary treatment unit into each tank in the device for circulating cleaning and dissolving chemicals, start the ultrasonic wave of the ultrasonic dispersion tank and start stirring, and clean the dirt in the tank , remove t...

Embodiment 3

[0087] This embodiment provides a device for circularly cleaning and dissolving chemicals, except that the number of ultrasonic transducer vibrators placed on one side of the vibrating plate shell in the ultrasonic transducer vibrating plate is 18, and the vibrators between adjacent ultrasonic transducer vibrating elements Except that the spacing is 60mm, other aspects are the same as the device for circulating cleaning and dissolving chemicals provided in Example 1.

[0088] This embodiment also provides a method of using the device of this embodiment to perform circular cleaning and dissolve the raw material of the ternary material precursor, the specific method is:

[0089] (1) Pass the deionized water produced by the cleaning liquid secondary treatment unit into each tank in the device for circulating cleaning and dissolving chemicals, start the ultrasonic wave of the ultrasonic dispersion tank and start stirring, and clean the dirt in the tank , remove the salt scale and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com