Dicyclopentadiene hydrogenated petroleum resin and preparation method thereof

A technology of hydrogenated petroleum resin and dicyclopentadiene, which is applied in the field of dicyclopentadiene hydrogenated petroleum resin and its preparation, can solve the problems of reduced catalyst activity, complex combined process flow, and incomplete conversion of DCPD, and overcome the defects , The effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment [1-10]

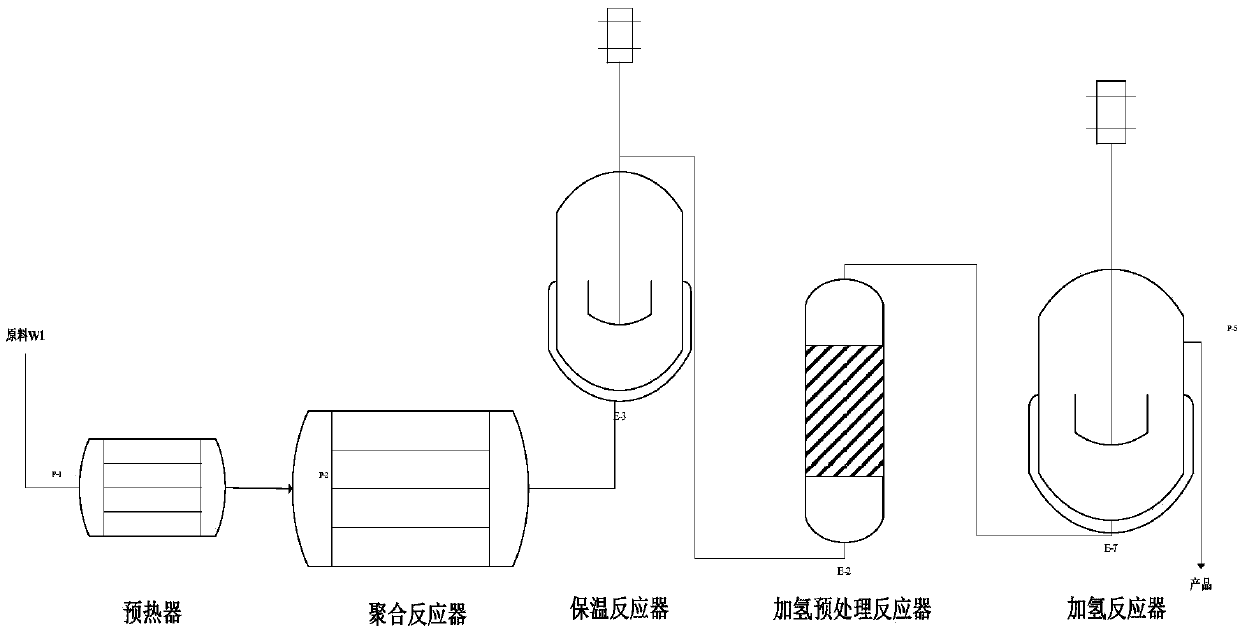

[0029] The technological process of embodiment 1~10 sees figure 1 , the raw material W1 is a material rich in DCPD, and its main composition is shown in Table 1. In the embodiment, the process operating conditions of the preheating reactor, the polymerization reactor, the heat preservation reactor, the hydrogenation pretreatment reactor and the hydrogenation reactor are respectively See Table 2, Table 3, Table 4, Table 5 and Table 6. Among them, macroporous sulfonic acid-based cation exchange resin is used for the catalyst bed in the pretreatment reaction before hydrogenation of petroleum resin, and a skeleton nickel catalyst is used for hydrogenation reaction. After the reaction, weigh and analyze the various indicators of the petroleum resin sample (softening point, molecular weight distribution and bromine value, etc.), the results are shown in Table 7. Adopt gel chromatography to measure resin product molecular weight distribution index (M w / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com