Modified m-pentadiene hydrogenated petroleum resin and preparation method thereof

A hydrogenated petroleum resin and piperylene technology, which is applied in the field of high-quality modified piperylene hydrogenated petroleum resin and its preparation, can solve the problems of complex combined process, reduced catalyst activity, and serious branching of polymer resins. , achieve the effect of simplifying process steps, promoting mixing and dispersing, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

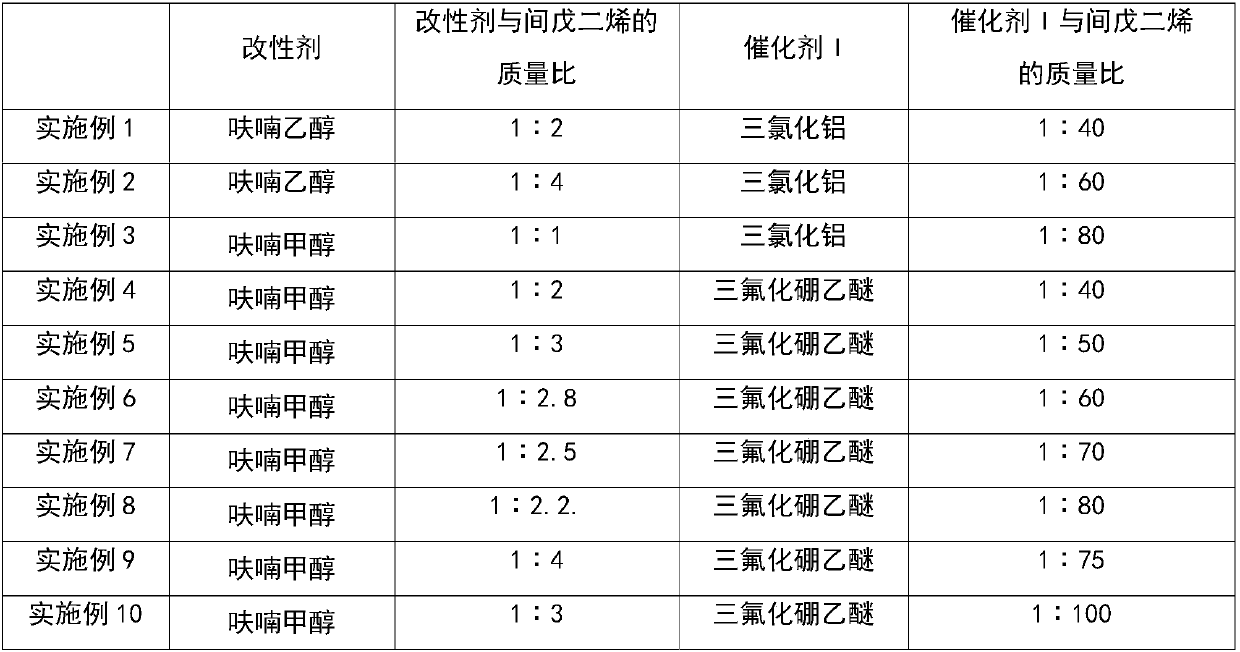

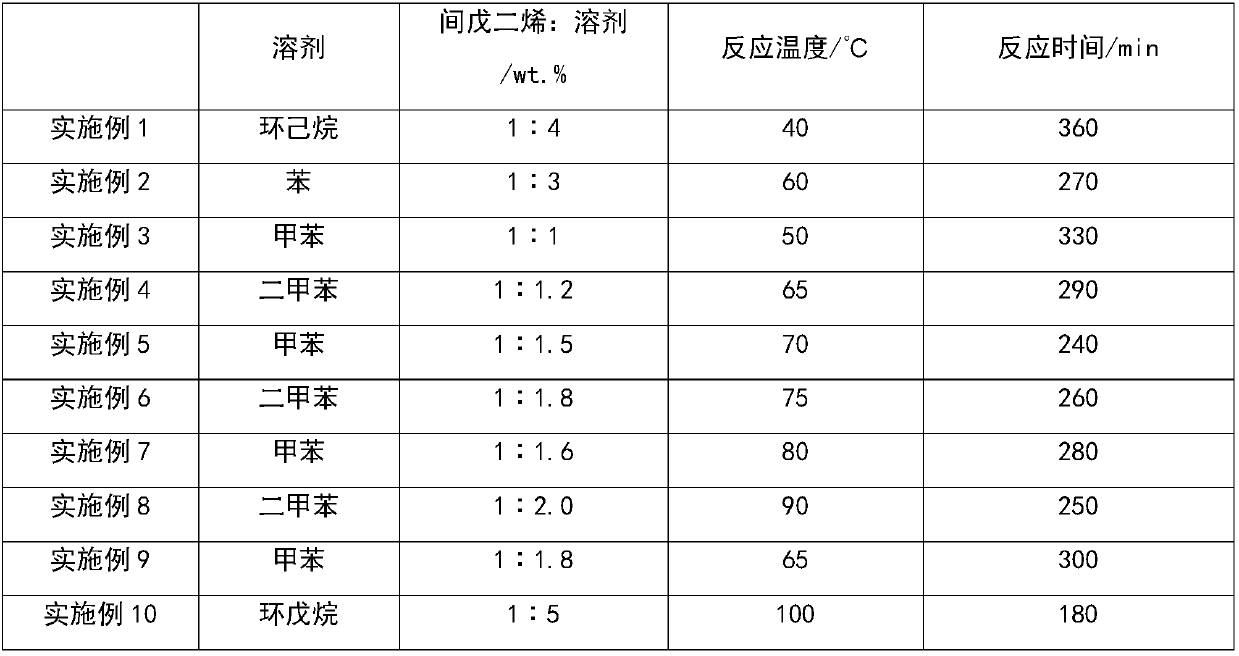

[0025] Embodiment [1-10]

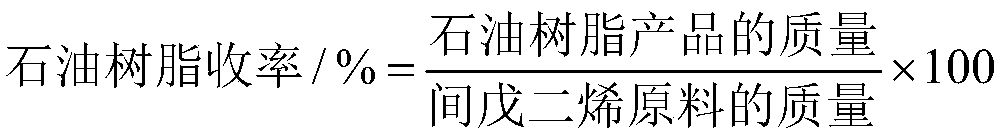

[0026] Embodiment 1~10 carries out the preparation of modified piperylene hydrogenated petroleum resin according to the following steps. ), Table 3 (step 1), table 4 (step 2), table 5 (step 3). After the reaction, weigh and analyze the various indicators of the resin sample (softening point, molecular weight distribution and bromine value, etc.), the results are shown in Table 5. Adopt gel chromatography to measure resin product molecular weight distribution index (M w / M n ), using the ring and ball method GB / 2294 to analyze the softening point, and using the iodometric method (SWB2301-62) to analyze the bromine value.

[0027] 1) piperylene, catalyst 1, modifying agent and organic solvent are added in the reactor, under normal pressure, carry out catalytic polymerization reaction, obtain piperylene modified petroleum resin polymerization liquid;

[0028] 2) the piperylene-modified petroleum resin polymer solution obtained in step 1) is passed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com