Preparation method and application of organic phosphine grafted hollow metal organic framework material

A metal-organic framework and organophosphine technology, which is applied in the field of preparation of organophosphine-grafted hollow metal-organic framework materials, can solve problems such as poor smoke suppression performance, achieve good mechanical properties, novel and simple method, and improve compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of organophosphine-grafted hollow zirconium metal-organic framework materials:

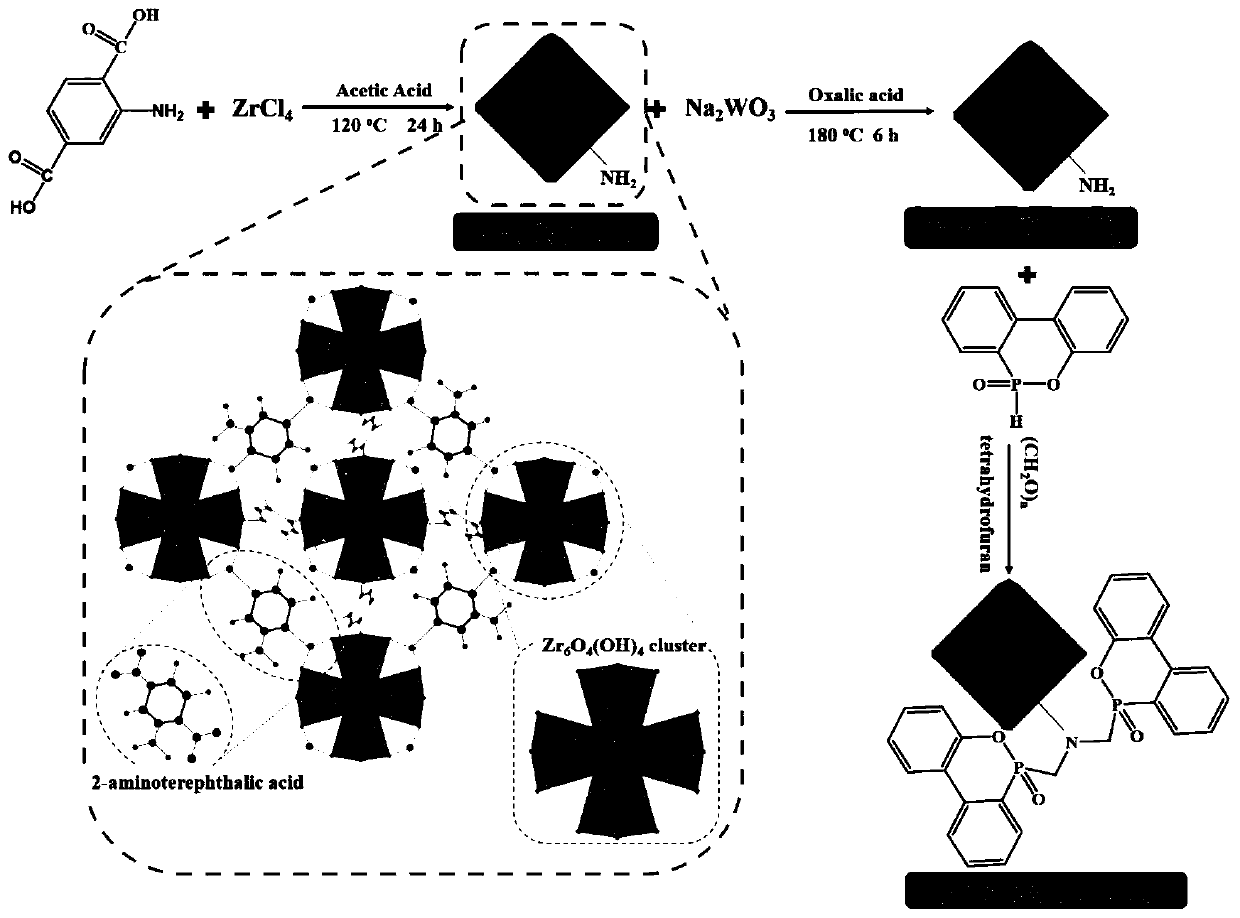

[0040] Such as figure 1 As shown, the specific steps of the preparation method of organophosphine grafted hollow metal organic framework materials include:

[0041] (1) Add 0.384g 2-aminoterephthalic acid, 0.54g zirconium tetrachloride, 120mL dimethylformamide (DMF) and 10mL acetic acid to the reaction vessel, stir at room temperature for 20min, pour the reaction solution into four In a vinyl fluoride reactor, react at 120°C for 24h, wash with DMF and methanol for 3 times, and vacuum dry at 60°C to obtain the zirconium metal organic framework (Zr-MOF-NH 2 ).

[0042] (2) Add 8.25g of sodium tungstate and 25mL of water into the reaction vessel, stir at room temperature for 30min, and use 2mol L -1 HCl to adjust the pH of the solution to 2.0, then add water to obtain a 250 mL solution, and add oxalic acid to adjust the pH of the solution to 2.3. Take 70mL solution and add i...

Embodiment 2

[0050] 1. Preparation of organophosphine-grafted hollow zirconium metal-organic framework materials:

[0051] Such as figure 1 As shown, the specific steps of the preparation method of organophosphine grafted hollow metal organic framework materials include:

[0052] (1) Add 0.384g 2-aminoterephthalic acid, 0.54g zirconium tetrachloride, 120mL dimethylformamide (DMF) and 10mL acetic acid to the reaction vessel, stir at room temperature for 20min, pour the reaction solution into four In a vinyl fluoride reactor, react at 120°C for 24h, wash with DMF and methanol for 3 times, and vacuum dry at 60°C to obtain the zirconium metal organic framework (Zr-MOF-NH 2 ).

[0053] (2) Add 8.25g of sodium tungstate and 25mL of water into the reaction vessel, stir at room temperature for 30min, and use 2mol L -1 HCl to adjust the pH of the solution to 2.0, then add water to obtain a 250 mL solution, and add oxalic acid to adjust the pH of the solution to 2.3. Take 70mL solution and add i...

Embodiment 3

[0063] 1. Preparation of organophosphine-grafted hollow zirconium metal-organic framework materials:

[0064] Such as figure 1 As shown, the specific steps of the preparation method of organophosphine grafted hollow metal organic framework materials include:

[0065] (1) Add 0.384g 2-aminoterephthalic acid, 0.54g zirconium tetrachloride, 120mL dimethylformamide (DMF) and 15mL acetic acid to the reaction vessel, stir at room temperature for 20min, pour the reaction solution into four In a vinyl fluoride reactor, react at 120°C for 24h, wash with DMF and methanol for 3 times, and vacuum dry at 60°C to obtain the zirconium metal organic framework (Zr-MOF-NH 2 ).

[0066] (2) Add 8.25g of sodium tungstate and 25mL of water into the reaction vessel, stir at room temperature for 30min, and use 2mol L -1 HCl to adjust the pH of the solution to 2.0, then add water to obtain a 250 mL solution, and add oxalic acid to adjust the pH of the solution to 2.3. Take 70mL solution and add i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com