Lubricating oil base oil and preparation method thereof

A technology of lubricating base oil and tungoleic acid, which is applied in the preparation of carboxylate, carboxylate, lubricating composition, etc., can solve the problems of high pour point and limited use, achieve low pour point and increase the degree of branching , the effect of high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

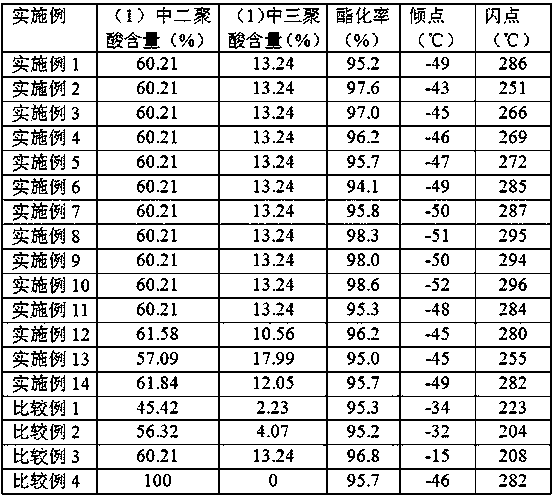

Examples

Embodiment 1

[0030] (1) Use commercial tungoleic acid (iodine value 150g / 100g, acid value 180mgKOH / g). Take 100 grams of commercial oleic acid in a 250 mL four-necked flask, add 0.5 g of tert-butylhydroquinone at the same time, stir at 300 rpm, purging with nitrogen for 30 min, heat up to 220 ° C for 4 h, stop heating, and separate by molecular distillation For purification, the distillation pressure of the molecular distillation apparatus is ≤2Pa, and the distillation temperature is 170°C to remove unreacted monoacids to obtain products mainly composed of dimer acids.

[0031] (2) Take 55.7g of the above-mentioned dimer acid-based product, 39.1g of isooctyl alcohol, put them in a 250mL four-neck flask, add 0.668g of p-toluenesulfonic acid as a catalyst, and react at 120°C for 4 hours to obtain a lubricating oil base oil products.

Embodiment 2

[0033] (1) Use commercial tungoleic acid (iodine value 150g / 100g, acid value 180mgKOH / g). Take 100 grams of commercial oleic acid in a 250 mL four-necked flask, add 0.5 g of tert-butylhydroquinone at the same time, stir at 300 rpm, purging with nitrogen for 30 min, heat up to 220 ° C for 4 h, stop heating, and separate by molecular distillation For purification, the distillation pressure of the molecular distillation apparatus is ≤2Pa, and the distillation temperature is 170°C to remove unreacted monoacids to obtain products mainly composed of dimer acids.

[0034] (2) Take 55.7g of the above dimer acid-based product, 39.1g of ethanol, put them in a 250mL four-neck flask, add 0.668g of p-toluenesulfonic acid as a catalyst, and react at 120°C for 4h to obtain a lubricating base oil product .

Embodiment 3

[0036](1) Use commercial tungoleic acid (iodine value 150g / 100g, acid value 180mgKOH / g). Take 100 grams of commercial oleic acid in a 250 mL four-necked flask, add 0.5 g of tert-butylhydroquinone at the same time, stir at 300 rpm, purging with nitrogen for 30 min, heat up to 220 ° C for 4 h, stop heating, and separate by molecular distillation For purification, the distillation pressure of the molecular distillation apparatus is ≤2Pa, and the distillation temperature is 170°C to remove unreacted monoacids to obtain products mainly composed of dimer acids.

[0037] (2) Take 55.7g of the above dimer acid-based product, 39.1g of n-butanol, put them in a 250mL four-neck flask, add 0.668g of p-toluenesulfonic acid as a catalyst, and react at 120°C for 4h to obtain a lubricating oil base oil products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com