Multilayer nickel plating and hydrogen removing technology for neodymium-iron-boron permanent magnet material

A permanent magnet material, multi-layer nickel plating technology, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve parts hydrogen embrittlement powder, low corrosion resistance, poor bonding force of electroplating layer and other problems, to achieve the effect of improving the hydrogen embrittlement and powdering of parts, improving the corrosion resistance and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described below.

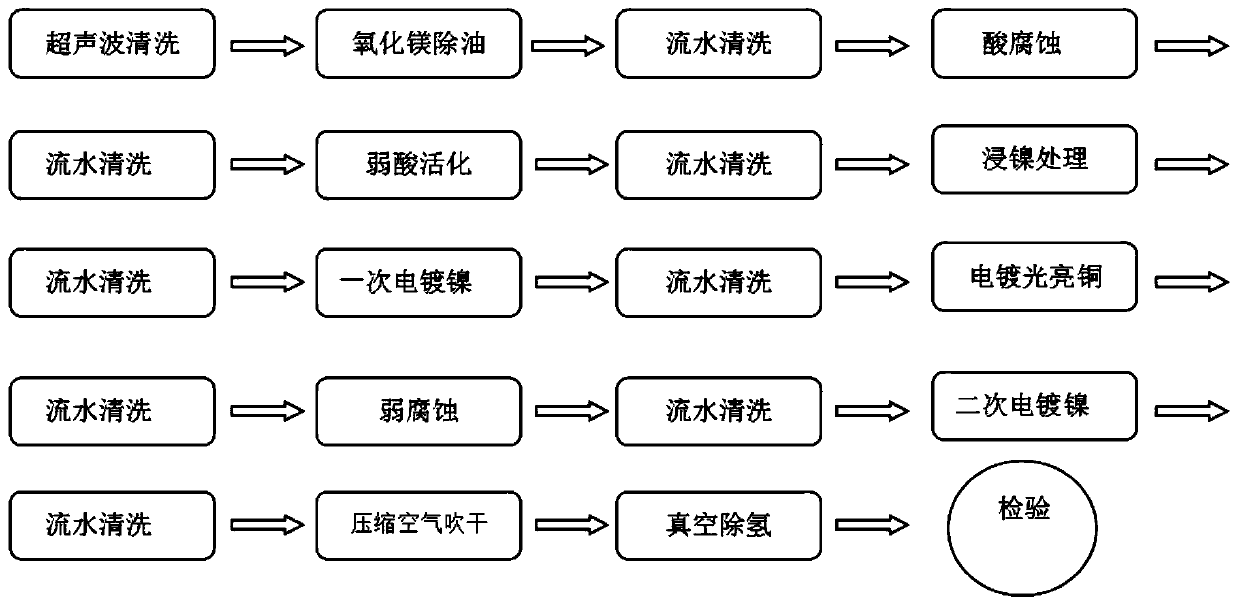

[0029] NdFeB permanent magnet material multi-layer nickel plating and hydrogen removal process, such as figure 1 shown, including the following steps:

[0030] 1) Ultrasonic cleaning: In order to remove tiny metal powder and impurities on the surface and pores of the parts, put the NdFeB permanent magnet material parts into the ultrasonic cleaning machine for cleaning. The temperature is 10-40°C;

[0031] 2) Magnesium oxide degreasing: In order to completely remove the oil stains on the parts, first mix the magnesium oxide powder with an appropriate amount of water into a paste, and then use a clean soft brush to dip in the paste-like magnesium oxide to wipe the NdFeB permanent magnet material parts and wait Plating surface 2 to 3 times, until the water film on the surface of the parts is even, clean with running water after degreasing;

[0032] 3) Acid corrosion: In order to remove oxides on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com