Pulse electroplating method based on dual-phase pulse

A pulse electroplating and reverse pulse technology, applied in the field of electroplating of printed circuit boards and semiconductor interconnections, can solve the problems of increasing process steps, increasing material loss, product scrap rate, signal attenuation, etc., achieving high efficiency, material saving and high efficiency , to avoid the effect of bag hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

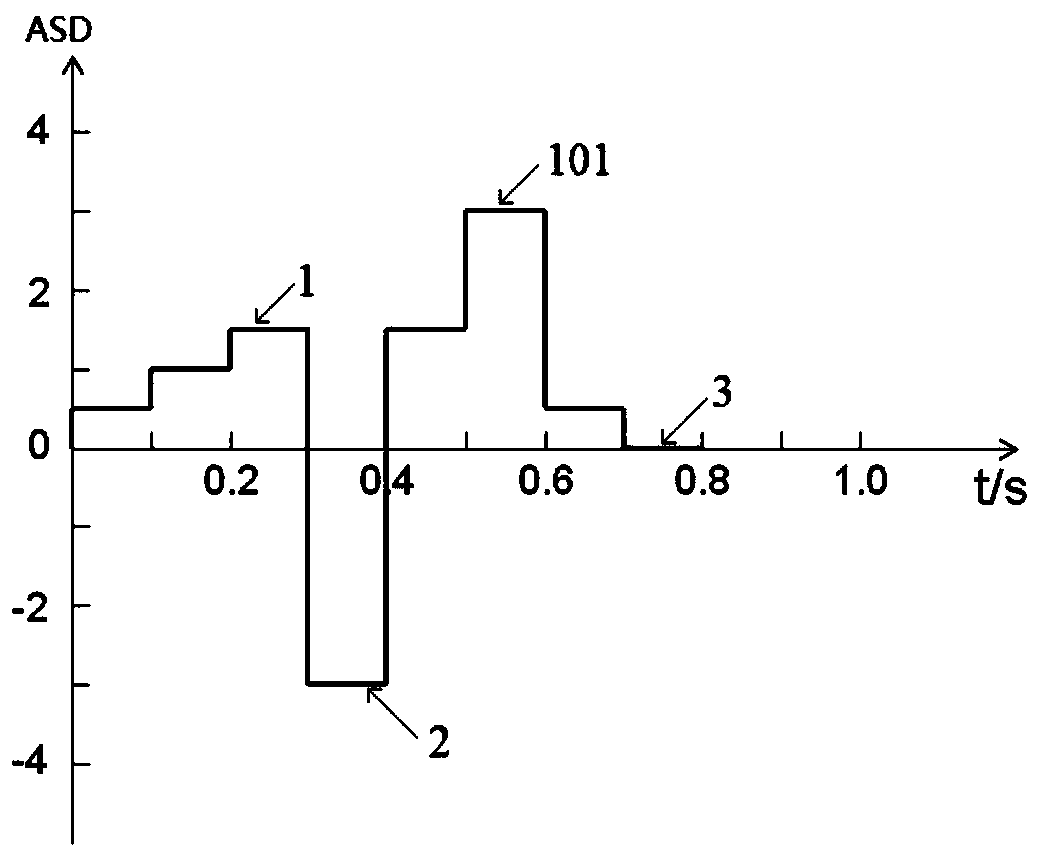

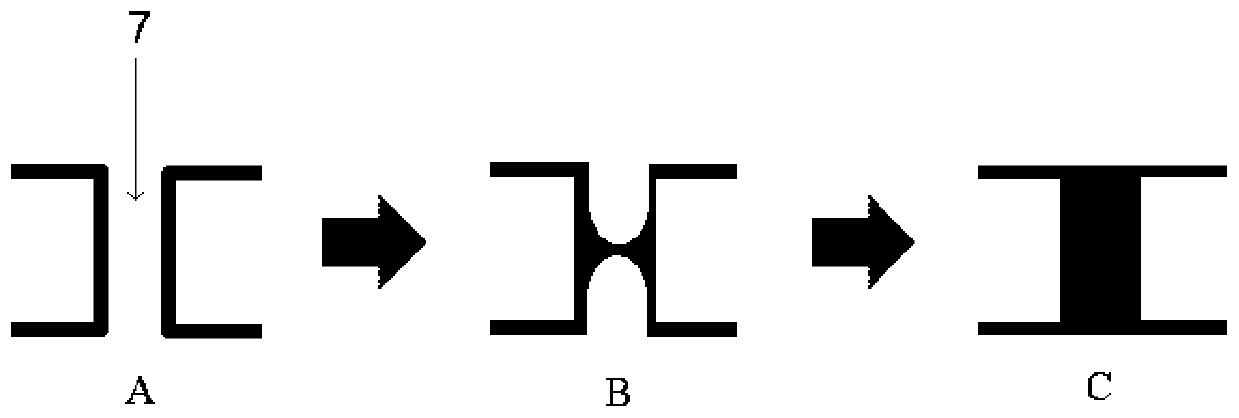

[0074] Embodiment 1 of the present invention provides a pulse electroplating method based on biphasic pulses, which includes the following steps: placing a ceramic material workpiece with a through hole aspect ratio of 5:1 through a substrate containing 11g / L Cu 2+ , 145g / L triethanolamine, 6g / L NaOH, 4g / L KNO 3 In the alkaline electroless copper plating solution, after electroplating at a current density of 1.5ASD at 55°C for 30s, a pre-copper-plated workpiece is obtained; the pre-copper-plated workpiece is placed in an acidic copper electroplating solution, and the anode It is a phosphorus copper ball with a phosphorus content of 0.05wt%. After pulse electroplating for 180 minutes on the component surface and the welding surface of the workpiece at 24° C., the processed workpiece is obtained.

[0075] Described acid electroplating copper solution comprises: 200g / LCuSO 4 ·5H 2 O, 85g / LH 2 SO 4 , 75mg / L NaCl, 10mL / L polyethylene glycol, 4.5mL / L sodium dimethylformamide sul...

Embodiment 2

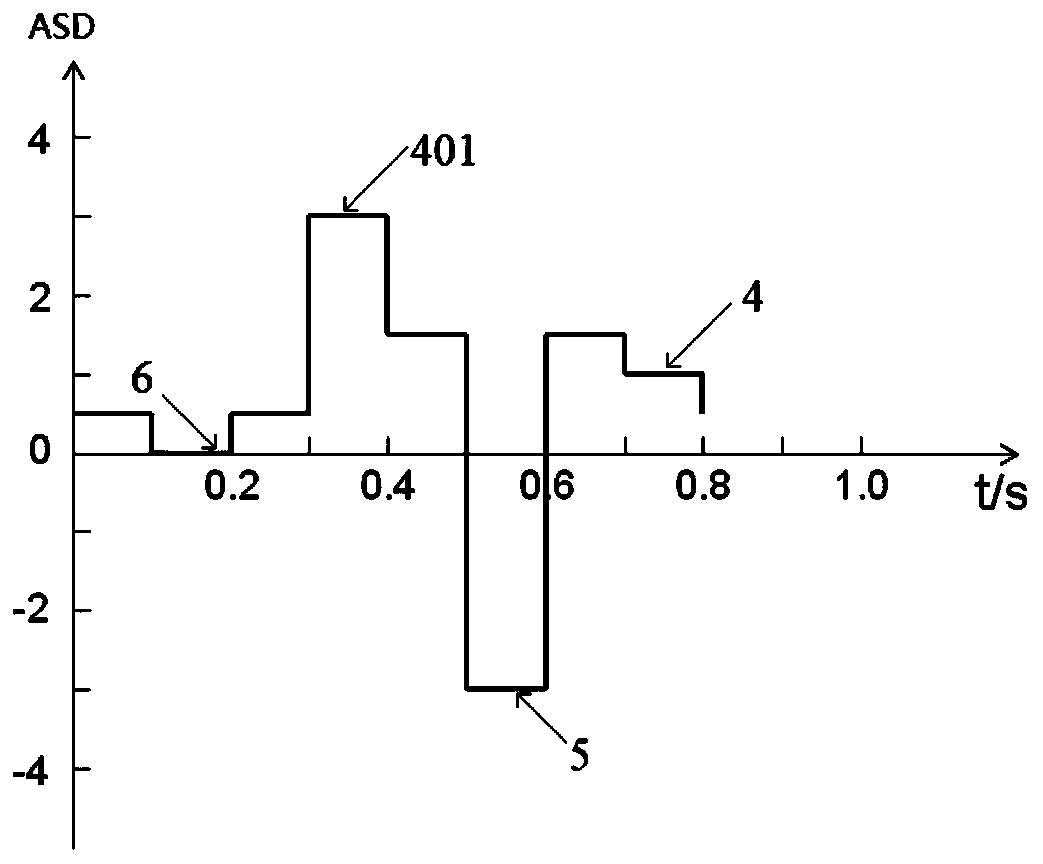

[0081] Embodiment 2 of the present invention provides a pulse electroplating method based on biphasic pulses, which includes the following steps: placing a ceramic material workpiece with a through hole aspect ratio of 3:1 through a substrate containing 11g / L Cu 2+ , 145g / L triethanolamine, 6g / L NaOH, 4g / L KNO 3 In the alkaline electroless copper plating solution, after electroplating at a current density of 1.5ASD at 55°C for 30s, a pre-copper-plated workpiece is obtained; the pre-copper-plated workpiece is placed in an acidic copper electroplating solution, and the anode It is a phosphor copper ball with a phosphorus content of 0.03 wt%, and pulse electroplating is performed on the component surface and the welding surface of the workpiece at 22° C. for 100 minutes to obtain the processed workpiece.

[0082] Described acid electroplating copper solution comprises: 180g / LCuSO 4 ·5H 2 O, 80g / LH 2 SO 4 , 60mg / L NaCl, 5.0mL / L polyethylene glycol, 1.0mL / L sodium dimethylforma...

Embodiment 3

[0088] Embodiment 3 of the present invention provides a pulse electroplating method based on biphasic pulses, which includes the following steps: placing a ceramic material workpiece with a through hole aspect ratio of 6:1 through a substrate containing 11g / L Cu 2+ , 145g / L triethanolamine, 6g / L NaOH, 4g / L KNO 3 In the alkaline electroless copper plating solution, after electroplating at a current density of 1.5ASD at 55°C for 30s, a pre-copper-plated workpiece is obtained; the pre-copper-plated workpiece is placed in an acidic copper electroplating solution, and the anode It is a phosphorus copper ball with a phosphorus content of 0.35wt%, and after performing pulse electroplating on the component surface and the welding surface of the workpiece for 250 minutes at 28° C., the processed workpiece is obtained.

[0089] Described acid electroplating copper solution comprises: 220g / LCuSO 4 ·5H 2 O, 110g / LH 2 SO 4 , 80mg / L NaCl, 30mL / L polyethylene glycol, 10mL / L sodium dimethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com