Porous anodic aluminum oxide cooling material, preparation method and application thereof to solar panel cooling

A technology of porous anode and aluminum oxide, which is applied in anodic oxidation, circuit, electrolytic coating, etc., can solve the problems of power generation efficiency decline, solar panel power generation power decline, and array service life reduction, so as to improve efficiency, reduce temperature, and improve The effect of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

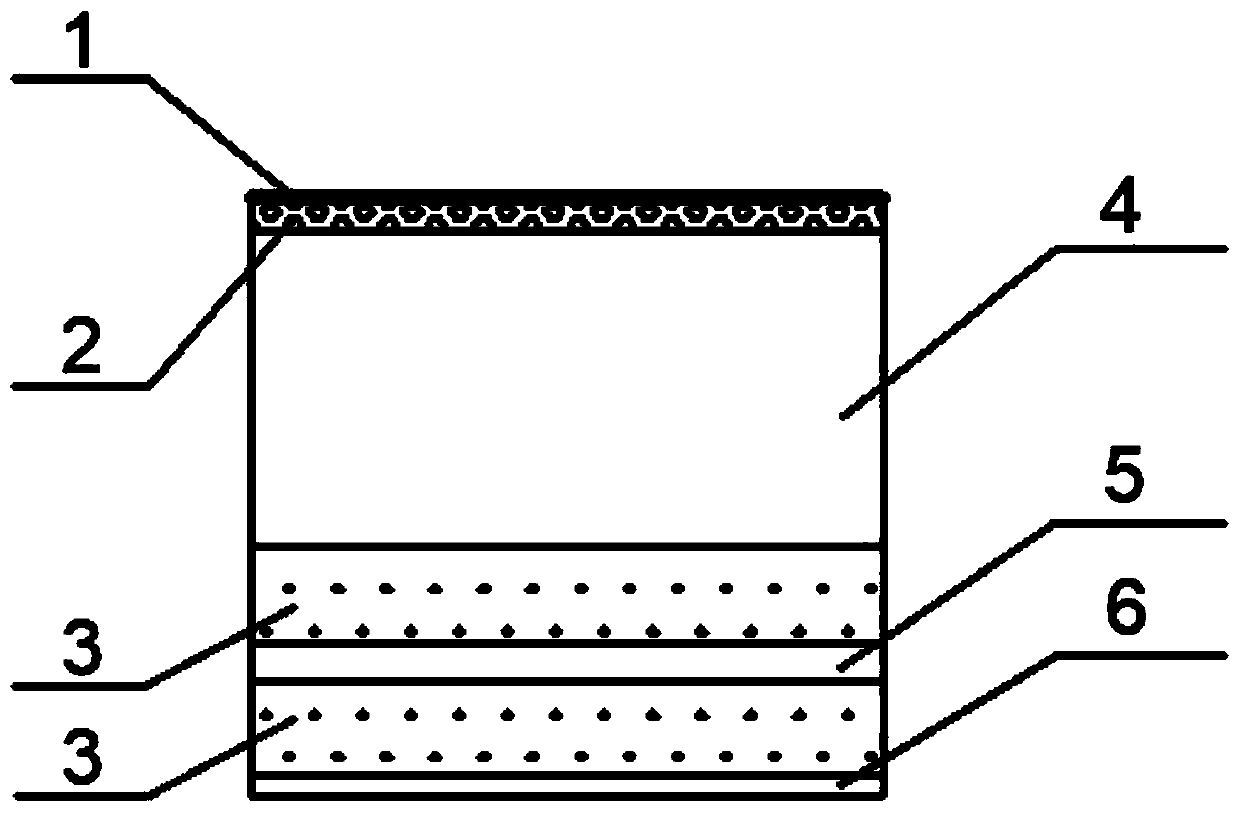

Image

Examples

Embodiment 1

[0026] A porous anodized aluminum oxide cooling material A, the preparation method of which is: using the principle of electrochemical oxidation to use pure aluminum as an anode, and a graphite carbon rod as a cathode, and place it in a container containing 5 wt% oxalic acid as an electrolyte, and the two electrodes Apply a constant voltage of 30V to the end, and use a magnetic stirrer to continuously stir the electrolyte at a speed of about 1000r / min. The entire device is placed in a low temperature environment of 1°C. After reaction 2, the sample is taken out, and the electrolyte is mixed with 3wt% chromium trioxide and 5vol% phosphoric acid The mixed solution removes the oxide film on the surface of the sample; the sample with the oxide film removed is subjected to the second reaction under the above conditions, and the reaction time is 15h. With the continuous oxidation of pure aluminum in the electrolyte and the continuous dissolution of the oxide film, the pure aluminum M...

Embodiment 2

[0029] A kind of porous anodic aluminum oxide cooling material B, its preparation method is: utilize electrochemical oxidation principle to use pure aluminum as anode, graphite carbon rod as cathode, be placed in the container that fills the phosphoric acid that concentration is 10wt% as electrolyte, electrode Apply a constant voltage of 60V at both ends, and use a magnetic stirrer to continuously stir the electrolyte at a speed of about 1000r / min. The entire device is placed in a low temperature environment of 3°C, and the sample is taken out after 4 hours of reaction. Using 3wt% chromium trioxide and 5vol% The mixed solution of phosphoric acid removes the oxide film on the surface of the sample; the sample with the oxide film removed undergoes a second reaction under the above conditions, and the reaction time is 20h. With the continuous oxidation of pure aluminum in the electrolyte and the continuous dissolution of the oxide film, the Micropores with different pore sizes are...

Embodiment 3

[0032] A kind of porous anodized aluminum oxide cooling material C, its preparation method is: utilize electrochemical oxidation principle to use pure aluminum as anode, graphite carbon rod as cathode, be placed in the container that fills the selenic acid that concentration is 20wt% as electrolyte, Apply a periodic current of 150-200mA to both ends of the electrode, and use a magnetic stirrer to continuously stir the electrolyte at a speed of about 1000r / min. Mixed solution with 5vol% phosphoric acid to remove the oxide film on the surface of the sample; the sample with the oxide film removed is subjected to the second reaction under the above conditions, and the reaction time is 25h. With the continuous oxidation of pure aluminum in the electrolyte and the continuous dissolution of the oxide film , form micropores with different pore sizes on the surface of pure aluminum. After the reaction, use a mixed solution of 5vol% hydrochloric acid and 1M copper chloride to remove unre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com