High-strength antibacterial composite resin for dental restoration and preparation method thereof

A composite resin and dental technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve problems such as stress fracture, secondary caries, etc., and achieve the effect of mild conditions, high biological safety, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

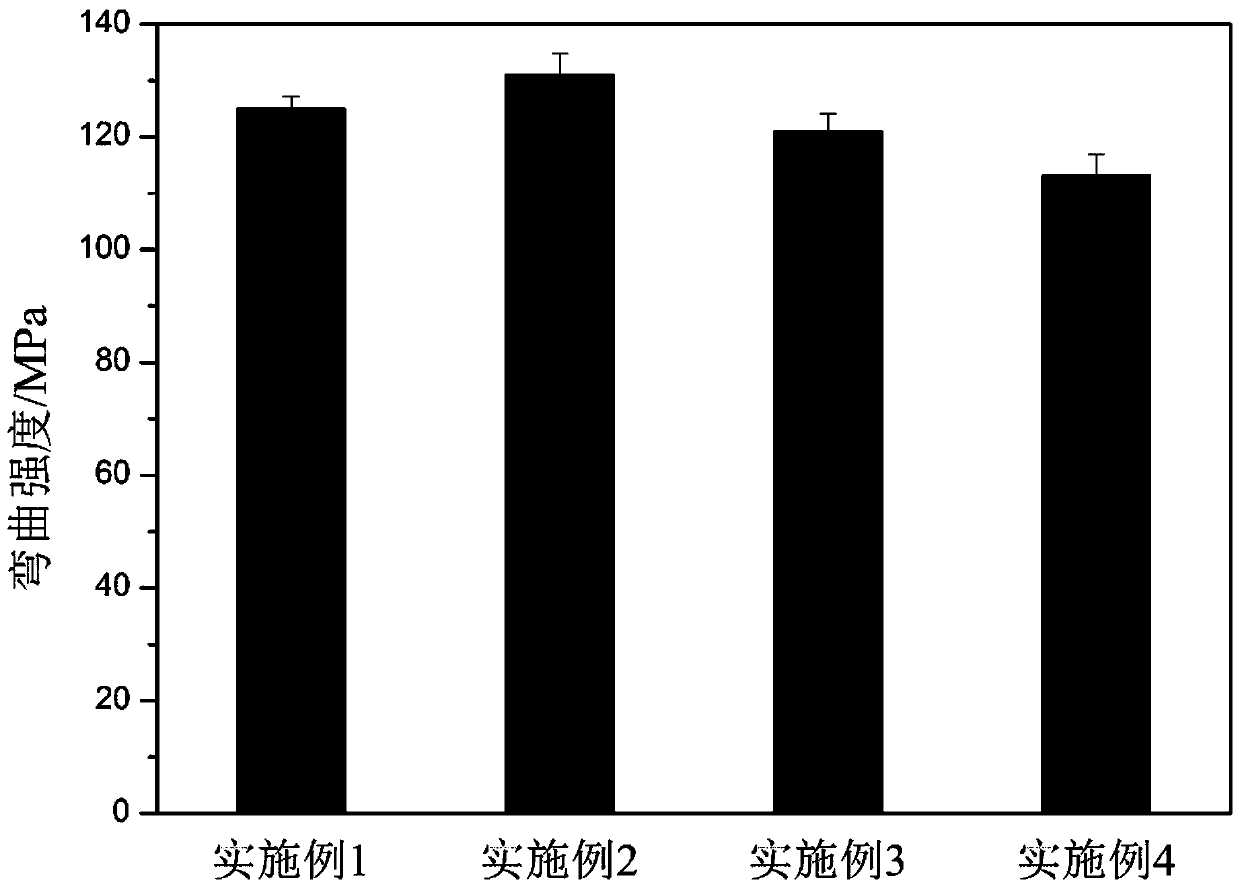

[0018] Example 1: The components of the composite resin and the mass percentages of each component are: Bis-GMA 44.25%, TEGDMA 44.25%, CQ 1%, 4-EDMAB 0.5%, zinc-doped mesoporous silica pellets 10 %.

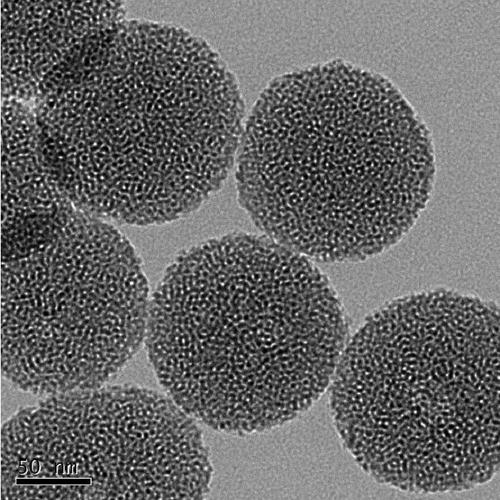

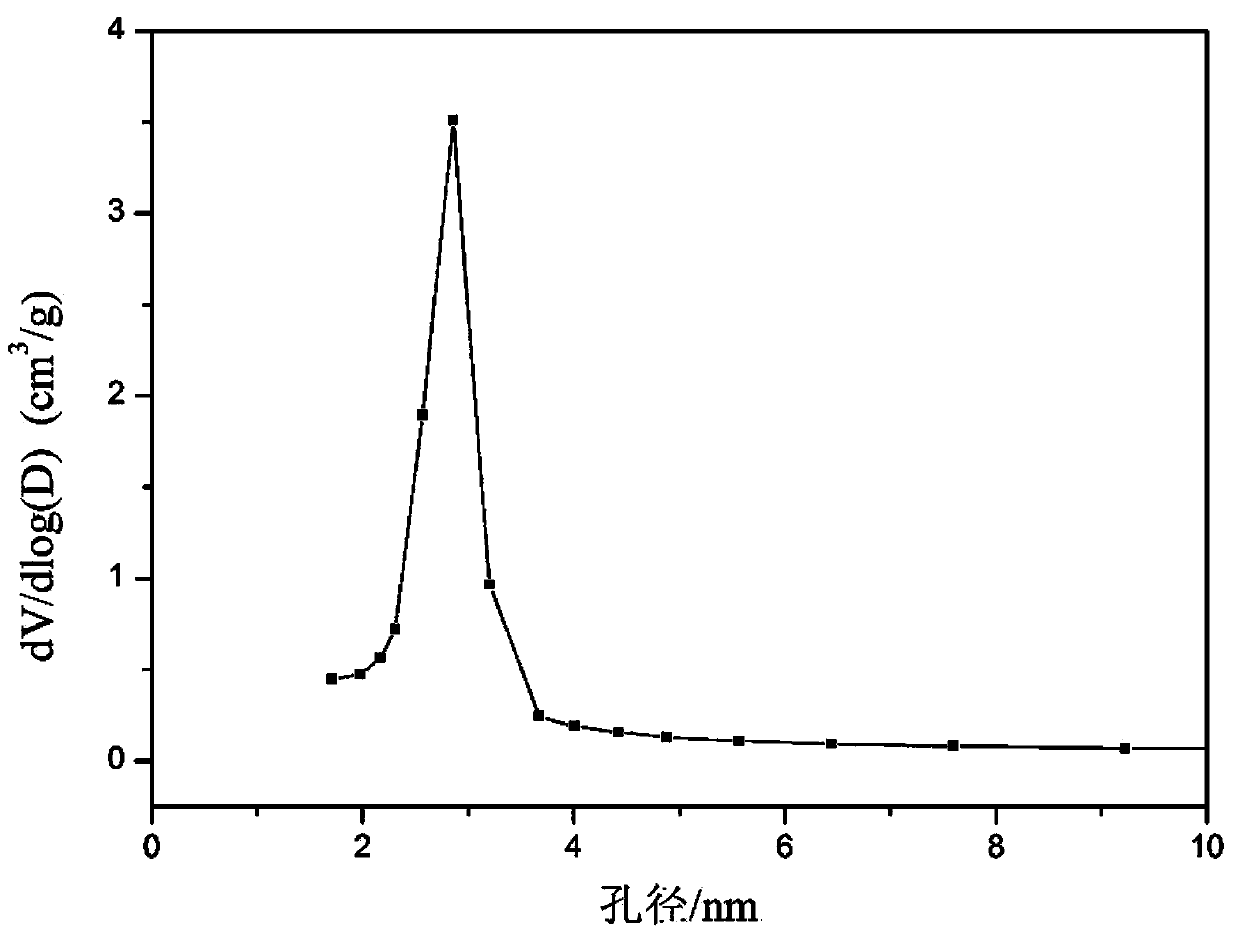

[0019] Preparation of zinc-doped silica pellets: 0.72 g CTAB, 1.2 g NH 4 F was added to 200 mL of deionized water in turn, and magnetically stirred in a constant temperature water bath at 80 °C for 1 h, 2 g of absolute ethanol, 1 g of Zn(NO 3 ) 2 ·6H 2 After O and 3.5 g TEOS were mixed evenly, they were added dropwise to the aqueous solution, and after magnetic stirring for 4 h, the precipitate obtained from the reaction was centrifuged, washed with deionized water and ethanol for 3 times, dried, and placed in a muffle furnace at 600 Calcined at ℃ for 6 h to obtain zinc-doped nanometer mesoporous silica powder.

[0020] Preparation of composite resin: Mix 4.425 g Bis-GMA, 4.425 g TEGDMA, 0.1 g CQ, 0.05 g 4-EDMAB and 1 g of zinc-doped mesoporous silica nanospheres evenly, put ...

Embodiment 2

[0022] Example 2: The components of the composite resin and the mass percentages of each component are: Bis-GMA 34%, TEGDMA 34%, CQ 1%, 4-EDMAB 1%, zinc-doped mesoporous silica pellets 15% .

[0023] Preparation of zinc-doped silica pellets: 0.72 g CTAB, 1.2 g NH 4 F was added to 200 mL of deionized water in turn, and magnetically stirred in a constant temperature water bath at 60 °C for 1 h, 2 g of absolute ethanol, 1 g of Zn(NO 3 ) 2 ·6H 2 After O and 6 gTEOS were mixed evenly, they were added dropwise to the aqueous solution, and after magnetic stirring for 4 h, the precipitate obtained in the reaction was centrifuged, washed with deionized water and ethanol for 3 times, dried, and placed in a muffle furnace at 600 Calcined at ℃ for 6 h to obtain zinc-doped nanometer mesoporous silica powder.

[0024] Preparation of composite resin: Mix 3.4 g Bis-GMA, 3.4 g TEGDMA, 0.1 g CQ, 0.1 g 4-EDMAB, and 1.5 g zinc-doped mesoporous silica nanospheres evenly, put them into a silico...

Embodiment 3

[0026] Example 3: The components of the composite resin and the mass percentages of each component are: Bis-GMA 40%, TEGDMA 23%, CQ 1%, 4-EDMAB 1%, zinc-doped mesoporous silica pellets 30% .

[0027] Preparation of zinc-doped silica pellets: 0.72 g CTAB, 1.2 g NH 4 F was added to 200 mL of deionized water in turn, and magnetically stirred in a constant temperature water bath at 40 °C for 1 h, 2 g of absolute ethanol, 0.5 g of Zn(NO 3 ) 2 ·6H 2 After O and 5 gTEOS were mixed evenly, they were added dropwise to the aqueous solution, and after magnetic stirring for 4 h, the precipitate obtained from the reaction was centrifuged, washed with deionized water and ethanol for 3 times, dried, and placed in a muffle furnace at 600 Calcined at ℃ for 6 h to obtain zinc-doped nanometer mesoporous silica powder.

[0028] Preparation of composite resin: Mix 4.0 g Bis-GMA, 2.3 g TEGDMA, 0.1 g CQ, 0.1 g 4-EDMAB, and 3 g zinc-doped mesoporous silica nanospheres evenly, put them into a sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com