Process and device for autotrophic biological denitrification of urban secondary effluent

A technology of autotrophic biological denitrification and secondary water effluent, which is applied in the field of wastewater treatment, can solve the problems of difficult control of nutrient matrix ratio, low pyrite solubility, large reactor volume, etc., and achieve shortened hydraulic retention time, pyrite Low consumption and high nitrogen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

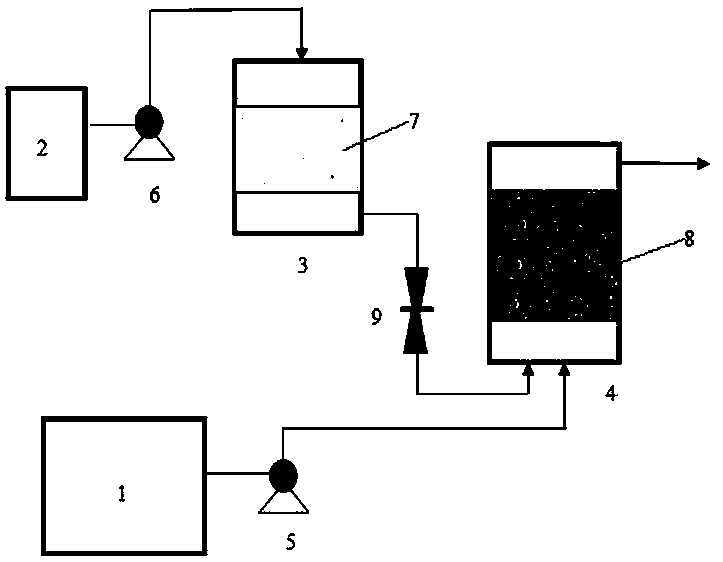

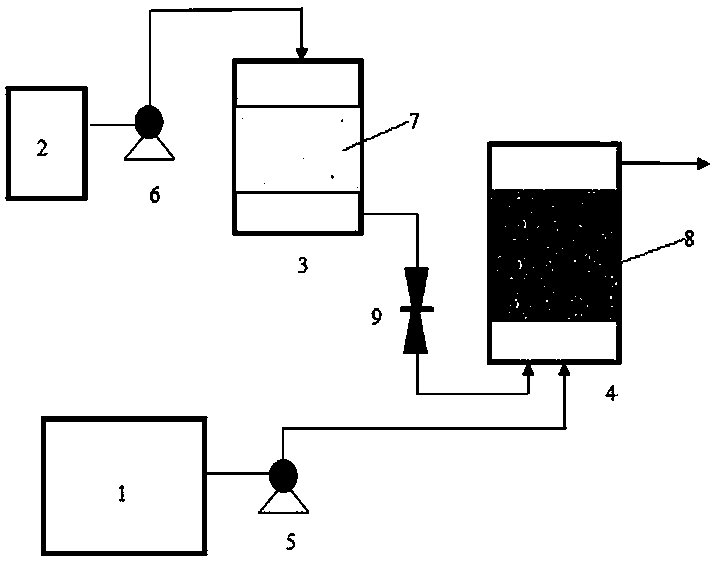

[0019] The present invention is a method for autotrophic denitrification using exogenous soluble pyrite, and the biological treatment system implementing the method of the present invention adopts an upflow reactor, such as figure 1 , the device of the present invention specifically comprises water inlet tank (1), acid storage tank (2), pyrite dissolving pond (3), biofilm denitrification pond (4), water inlet pump (5), metering pump (6) , a pyrite packed bed (7), a biological packed bed (8), and a flow metering device (9). The phosphorus removal method in the biofilm denitrification reactor is mainly chemical phosphorus removal, and the system can maintain a high biomass.

[0020] By separating the pyrite dissolution pool (3) and the biofilm denitrification pool (4), adding acid to the pyrite packing bed (7) of the pyrite dissolution pool (3) promotes pyrite dissolution, and at the same time Produce ferrous ions, elemental sulfur and sulfur ions that can be used as electron d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com