A kind of anti-compression anti-carbonation recycled concrete and its preparation method

A recycled concrete and anti-carbonation technology, applied in the field of concrete, can solve the problems of reducing the compressive strength of concrete, aggravating concrete carbonation, and low anti-carbonation ability, so as to improve anti-carbonation performance, protect the ecological environment, and excellent anti-compression and anti-carbonation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

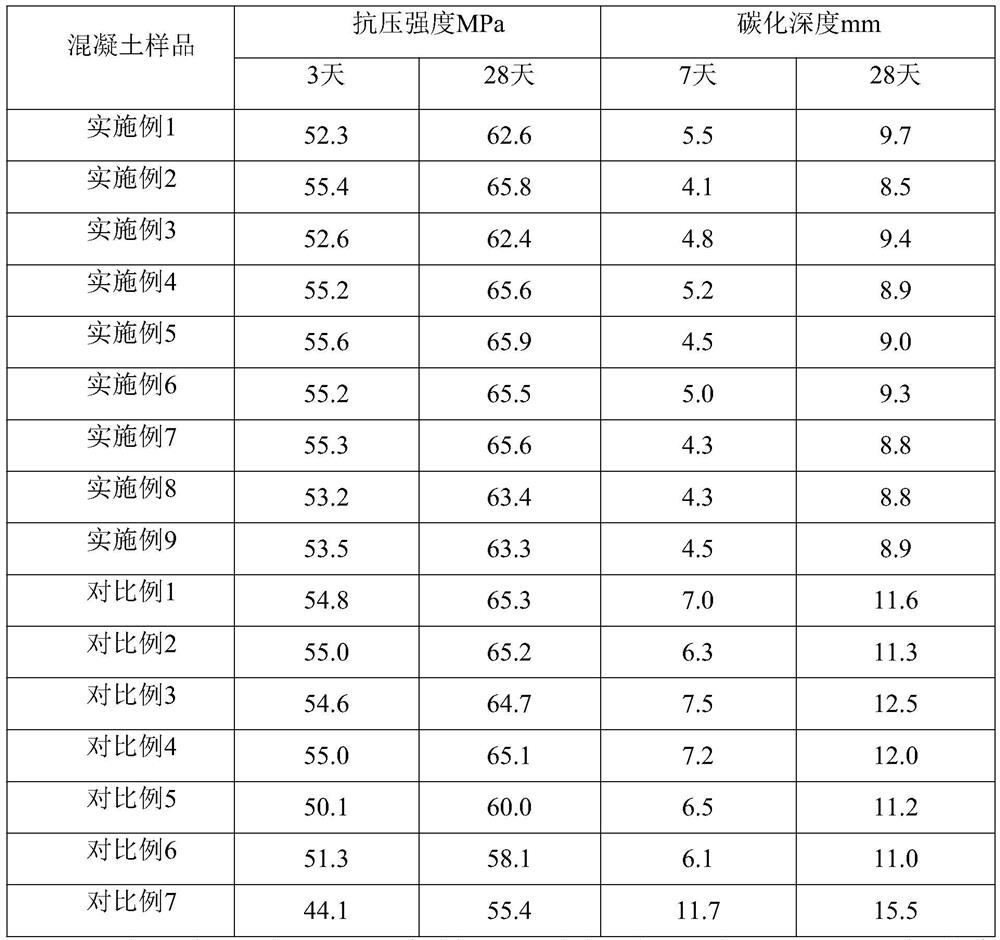

Examples

Embodiment 1

[0049] A compressive and anti-carbonation recycled concrete, comprising the following components in parts by weight: 250 parts of cement, 70 parts of silica fume, 30 parts of fly ash, 1120 parts of modified recycled coarse aggregate, 700 parts of sand, 15 parts of dispersed latex powder, 3 parts of water reducer, 160 parts of water;

[0050] The preparation of anti-compression and anti-carbonation recycled concrete includes the following steps:

[0051] a, in parts by weight, mix 100 parts of water glass with a mass concentration of 5%, 20 parts of diatomaceous earth, 20 parts of zeolite powder, 8 parts of colloidal graphite powder, and 3 parts of silane coupling agent to obtain aggregate modification solution; b, soak the recycled coarse aggregate raw material in the aggregate modification solution for 40 minutes, take it out and drain it, and roast it at 180°C for 1 hour to obtain the modified recycled coarse aggregate; c, mix cement, sand, and redispersible latex Powder and ...

Embodiment 2

[0053] A compressive and anti-carbonation recycled concrete, comprising the following components in parts by weight: 270 parts of cement, 62 parts of silica fume, 40 parts of fly ash, 1100 parts of modified recycled coarse aggregate, 720 parts of sand, 12 parts of dispersed latex powder, 4 parts of water reducing agent, and 150 parts of water, wherein the weight ratio of cement, silica fume and fly ash is 1:0.23:0.15;

[0054] The preparation of anti-compression and anti-carbonation recycled concrete includes the following steps:

[0055] a, in parts by weight, mix 100 parts of water glass with a mass concentration of 5%, 25 parts of diatomaceous earth, 15 parts of zeolite powder, 12 parts of colloidal graphite powder, and 2 parts of silane coupling agent to obtain aggregate modification Liquid, wherein, the weight ratio of diatomite and zeolite powder is 1:0.6;

[0056] b. Soak the recycled coarse aggregate raw material in the aggregate modification solution for 50 minutes, ...

Embodiment 3

[0058] A compressive and anti-carbonation recycled concrete, comprising the following components in parts by weight: 290 parts of cement, 55 parts of silica fume, 45 parts of fly ash, 1050 parts of modified recycled coarse aggregate, 730 parts of sand, 10 parts of dispersed latex powder, 5 parts of water reducer, 140 parts of water;

[0059] The preparation of anti-compression and anti-carbonation recycled concrete includes the following steps:

[0060] a, in parts by weight, mix 100 parts of water glass with a mass concentration of 5%, 30 parts of diatomaceous earth, 10 parts of zeolite powder, 15 parts of colloidal graphite powder, and 1 part of silane coupling agent to obtain aggregate modification solution; b, soak the recycled coarse aggregate raw material in the aggregate modification solution for 60 minutes, take it out and drain, and roast at 200°C for 2 hours to obtain the modified recycled coarse aggregate; c, mix cement, sand, and redispersible latex Powder and wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com