Multi-compartment energy-saving aerobic composting device and composting method thereof

An aerobic composting and composting method technology, applied in the field of composting, can solve the problems of complex process, unsafe composting environment, high energy consumption, etc., and achieve the effects of improving composting efficiency, preventing flies from gathering, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

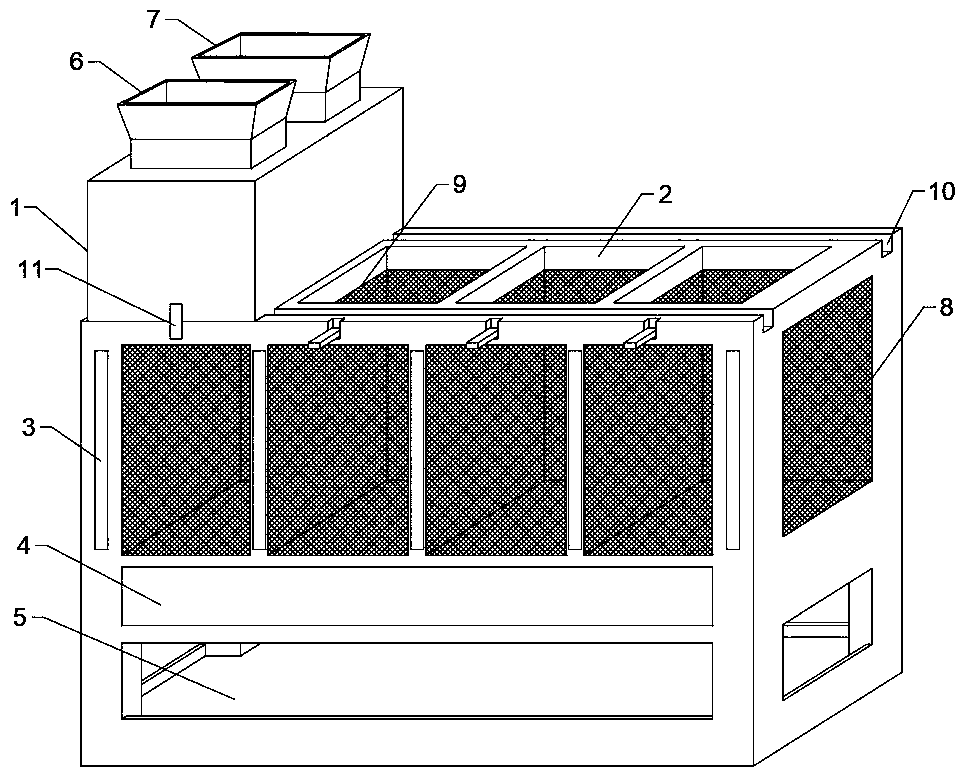

[0043] Such as figure 1 The multi-compartment energy-saving aerobic composting device shown includes a crushing and mixing chamber 1, a fermentation and decomposing chamber 2, an exhaust gas isolation layer 3, a leachate treatment layer 4, and a leachate indicator layer 5 arranged in sequence from top to bottom.

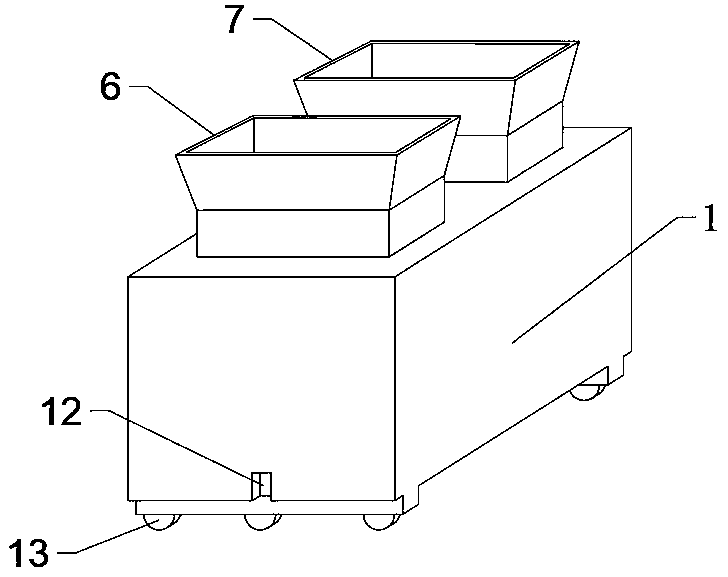

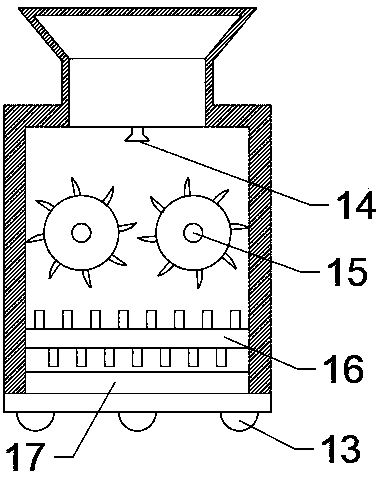

[0044] Such as figure 2 and image 3 As shown, the top of the crushing and mixing chamber 1 is provided with a first material inlet 6 and a second material inlet 7, and the bottom is provided with a material outlet 17; the crushing and mixing chamber 1 is provided with a biaxial crushing knife 15. The wall body on the upper part of the crushing knife 15 is provided with a bacteria liquid sprayer 14, and the lower part of the biaxial crushing knife 15 is provided with an agitator 16; The body is provided with a fixed groove 12; the crushing and mixing chamber 1 is movably installed in the guide rail 10 on the upper part of the fermentation and decomposing chamber 2...

Embodiment 2

[0058] Compared with Embodiment 1, the difference of the multi-compartment aerobic composting device of the present embodiment is:

[0059] Described spacer 8 aperture is 6mm;

[0060] The aperture of the outer spacer 9 is 4cm;

[0061] The aperture of the inner spacer 18 is 3mm;

[0062] The width of the exhaust gas insulation layer is 8cm;

[0063] The distance between the leachate treatment layer 4 and the leachate indicator layer 5 is 25 cm.

[0064] The difference of present embodiment composting method is:

[0065] Fill lavender, coconut dregs, camphor sawdust, mature fertilizer in the described waste gas insulation layer 3;

[0066] The filling thickness of the mature fertilizer and activated carbon of leachate treatment 23 is 20cm, and the mass ratio is 6:4;

[0067] The fill thickness of the leachate indicator 24 is 10 cm.

[0068] The input ratio of garden waste and kitchen waste is 1:3.

Embodiment 3

[0070] Compared with Embodiment 1, the difference of the multi-compartment aerobic composting device of the present embodiment is:

[0071] Described spacer 8 apertures are 5mm;

[0072] The aperture of the outer spacer 9 is 4cm;

[0073] The aperture of the inner spacer 18 is 3mm;

[0074] The width of the exhaust gas insulation layer is 6cm;

[0075] The distance between the leachate treatment layer 4 and the leachate indicator layer 5 is 20 cm;

[0076] The input ratio of garden waste and kitchen waste is 1:2.

[0077] The difference of present embodiment composting method is:

[0078] Fill lemongrass, mugwort, lavender, coconut dregs, camphor sawdust, mature fertilizer in the described waste gas insulation layer 3;

[0079] The filling thickness of the mature fertilizer and activated carbon of the leachate treatment object 23 is 18cm, and the mass ratio is 7:3;

[0080] The fill thickness of the leachate indicator 24 is 8 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com