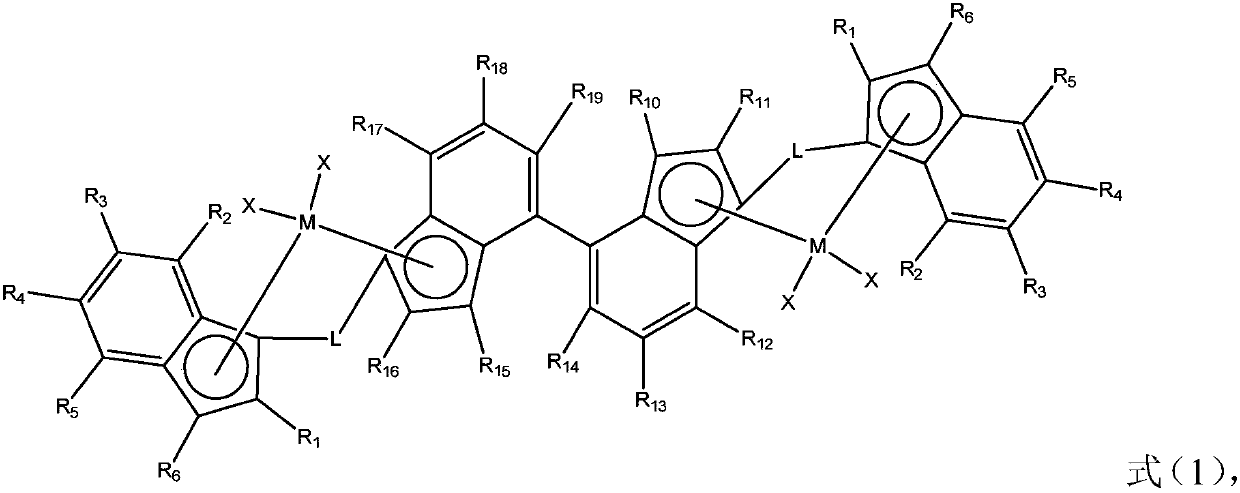

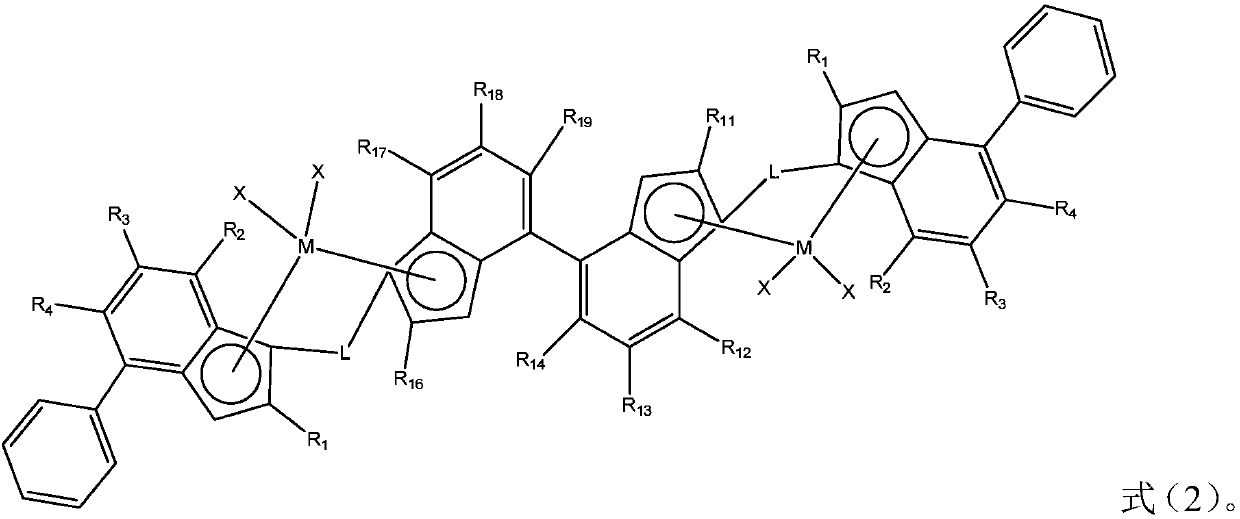

Binuclear metallocene supported catalyst, preparation method and applications thereof

A supported catalyst and metallocene compound technology, applied in the field of olefin polymerization, can solve the problems of low polymer isotacticity and insufficient catalyst activity, and achieve the effect of good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0119] Used to illustrate the preparation of compound A shown in formula (a).

[0120] With the compound shown in formula (7) as starting material,

[0121]

[0122] 24.55mL (0.20mol) of 2-bromotoluene in 40mL of tetrahydrofuran was slowly dropped into a three-necked flask containing 4.91g (0.20mol) of Mg powder and 10mL of tetrahydrofuran. The reaction system was gradually warmed up to reflux state and kept for 3h.

[0123] After the reaction was cooled to room temperature, a catalytic amount of NiCl was added 2 (about 0.1g), and a mixed solution of 21.06mL (0.20mol) of bromobenzene and 10mL of tetrahydrofuran was added dropwise, and the reaction was refluxed at 50-55°C for 3-5h.

[0124] After the THF was removed by rotary evaporation, the mixture was poured into 500 mL of ice water, and the pH value of the solution was adjusted to about 1 with 6M hydrochloric acid, and the organic matter was extracted with 3×60 mL of ether, MgSO 4 Dry, filter, and remove ether by rota...

preparation example 2

[0147] For illustrating the compound B shown in the preparation formula (b)

[0148] With the compound shown in formula (11) as starting material,

[0149]

[0150] Dissolve 1.86g (0.081mol) of Na in 50mL of absolute ethanol, add 14.60mL (0.081mol) of a mixture of diethyl methylmalonate and absolute ethanol dropwise, stir well, and slowly drop Add 20.00g (0.081mol) and 20 mL of absolute ethanol. A white precipitate was produced, and the mixture was heated to reflux at 100° C. for 3 h.

[0151] The product was cooled to room temperature, and aqueous KOH (16 g KOH dissolved in 45 mL water) was added, and the mixture was heated to reflux at 100° C. for 4 h. The solid gradually dissolves, and the solution is orange-red or brown-red.

[0152] After the reaction, the solvent ethanol was removed, water was added to dissolve the mixture completely and the pH was adjusted to 1 with 6M HCl, the yellow precipitate was filtered out and dried. The obtained solid was decarboxylated...

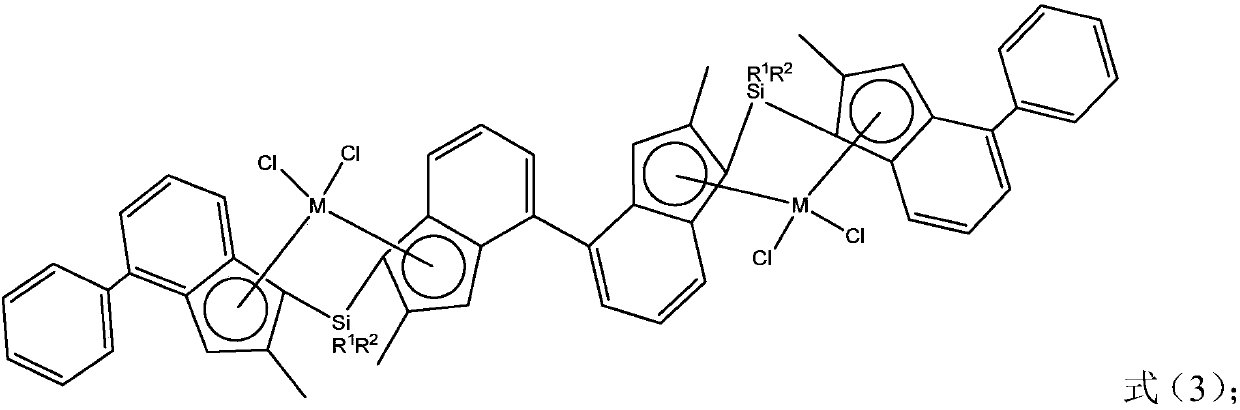

Embodiment 1

[0166] At 0°C, 4.41 mL (0.013 mol) of butyl lithium / hexane solution (2.86 mol / L), slowly rising to room temperature and reacting for 12 hours, a large amount of orange-red precipitated precipitation mother liquor was obtained.

[0167] The precipitated mother liquor was cooled to -25°C. Carefully add 2.39g (0.0126mol) of zirconium tetrachloride, stir the reaction, keep at -25°C for 0.5h, and slowly rise to room temperature for 24h.

[0168] Filter, wash the precipitate with 50 mL of toluene, and combine the filtrates. Part of the solvent was distilled off under reduced pressure, hexane was added dropwise until a precipitate occurred, and a very small amount of toluene was added to dissolve the precipitate. The solution was crystallized at -20°C, filtered to obtain orange-red crystals, and dried to obtain 3.97 g of Yield: 70%.

[0169] The product was determined by mass spectrometry. Determined as the binuclear metallocene compound shown in the above formula, denoted as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com