Preparation method of graphene/epoxy resin composite material

A technology of epoxy resin and composite materials, which is applied in the field of graphene materials, can solve the problems of reduced electrical conductivity and graphene limitations, and achieve the effects of enhanced tensile strength, increased flame retardancy, electrical conductivity, and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

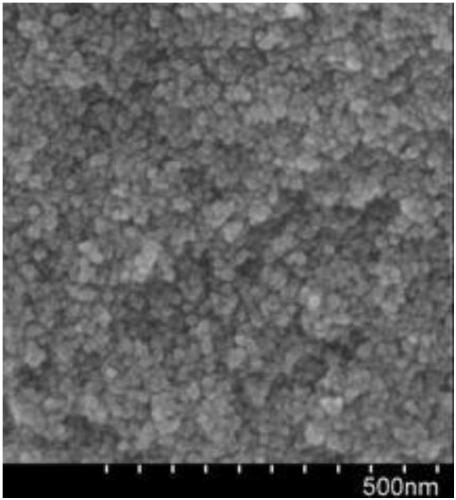

Image

Examples

Embodiment 1

[0025] A kind of preparation method of graphene / epoxy resin composite material, specifically comprises the following steps:

[0026] Step 1, the preparation of graphene dispersion liquid: at 0 o C, under the condition that the ICA stirrer is stirring at a constant speed, the graphene powder is fully mixed with the solvent first, and then the dispersant is added and ultrasonically mixed for 40 minutes to obtain a uniformly mixed graphene dispersion;

[0027] Step 2, place the container containing the graphene dispersion in an ice-water bath, add epoxy resin particles evenly and slowly while stirring, and perform high-intensity ultrasonic oscillation for 2 h with an ultrasonic degrader;

[0028] Step 3, the container containing the mixed solution obtained in step 2 is placed in the ICA stirrer in the fume hood, and stirred at a speed of 1000 r / min for 60 min at room temperature;

[0029] Step 4, place the mixed solution obtained in step 3 at 80 o 8 h in an oven at C to remove ...

Embodiment 2

[0035] A kind of preparation method of graphene / epoxy resin composite material, specifically comprises the following steps:

[0036] Step 1, the preparation of graphene dispersion liquid: in 4 o C, under the condition that the ICA stirrer is stirring at a constant speed, the graphene powder is fully mixed with the solvent first, and then the dispersant is added and ultrasonically mixed for 30 minutes to obtain a uniformly mixed graphene dispersion;

[0037] Step 2, place the container containing the graphene dispersion in an ice-water bath, add epoxy resin particles evenly and slowly while stirring, and perform high-intensity ultrasonic oscillation for 1.5 h with an ultrasonic degrader;

[0038] Step 3, the container containing the mixed solution obtained in step 2 is placed in the ICA stirrer in the fume hood, and stirred at a speed of 1100 r / min for 40 min at room temperature;

[0039] Step 4, place the mixed solution obtained in step 3 at 90 o C in the oven for 6 h to rem...

Embodiment 3

[0045] A kind of preparation method of graphene / epoxy resin composite material, specifically comprises the following steps:

[0046] Step 1, the preparation of graphene dispersion liquid: in 6 o C, under the condition that the ICA stirrer is stirring at a constant speed, the graphene powder is fully mixed with the solvent first, and then the dispersant is added and ultrasonically mixed for 20 minutes to obtain a uniformly mixed graphene dispersion;

[0047] Step 2, place the container containing the graphene dispersion in an ice-water bath, add epoxy resin particles evenly and slowly while stirring, and perform high-intensity ultrasonic oscillation for 2 h with an ultrasonic degrader;

[0048] Step 3, the container containing the mixed solution obtained in step 2 is placed in the ICA stirrer in the fume hood, and stirred at a speed of 1200 r / min for 35 min at room temperature;

[0049] Step 4, place the mixed solution obtained in step 3 at 100 o C in the oven for 5 h to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com