Wear-resistant pen refill and preparation method thereof

A wear-resistant and refill technology, applied in the field of refill manufacturing, can solve the problems of limited graphite hardness, fast consumption, poor wear resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

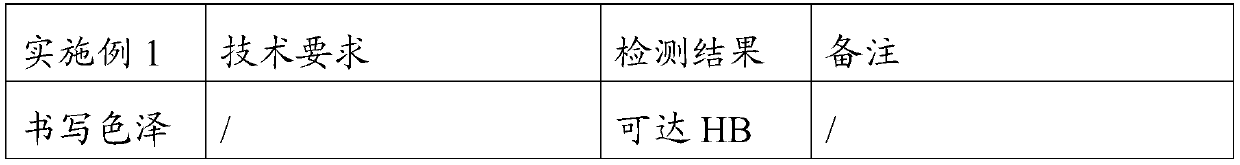

Embodiment 1

[0029] A wear-resistant refill, its raw materials include 30 parts of carbon powder, 20 parts of phenolic resin, 0.1 part of pitch, 1.5 parts of iron powder, 2 parts of boron, and 0.8 part of phosphorus according to parts by mass; wherein, carbon powder, iron powder, boron , The particle size range of phosphorus is 50 mesh to 1000 mesh.

[0030] The preparation method of the above-mentioned wear-resistant pen core includes:

[0031] Step 1: First mix the raw materials according to the proportion to form a paste, and extrude it into a blank with an extrusion strength of 450MPa;

[0032] Step 2: preheating the blank under vacuum conditions, the preheating temperature is 360°C, and then calcining at 650°C under the protection of nitrogen;

[0033] Step 3: Process the calcined material to obtain a rough material for the wear-resistant pen core.

Embodiment 2

[0035] A wear-resistant refill, its raw materials include 60 parts of carbon powder, 10 parts of phenolic resin, 0.5 part of pitch, 2 parts of iron powder, 0.1 part of boron, 0.7 part of phosphorus, and 0.1 part of bismuth powder according to parts by mass; wherein, carbon powder , iron powder, boron, phosphorus, bismuth powder particle size range from 50 mesh to 1000 mesh.

[0036] The preparation method of the above-mentioned wear-resistant pen core includes:

[0037] Step 1: First mix the raw materials according to the proportion to form a paste, and extrude it into a blank with an extrusion strength of 550MPa;

[0038] Step 2: preheating the blank under vacuum conditions, the preheating temperature is 220°C, and then calcining at 810°C under the protection of nitrogen;

[0039] Step 3: Process the calcined material to obtain a rough material for the wear-resistant pen core.

Embodiment 3

[0041] A wear-resistant refill, its raw materials include 40 parts by mass of carbon powder, 15 parts of phenolic resin, 1.5 parts of pitch, 1 part of iron powder, 1 part of boron, 1 part of phosphorus, 1 part of indium powder, and 0.9 parts of copper powder ; Among them, the particle size range of carbon powder, iron powder, boron, phosphorus, indium powder and copper powder is 50 mesh to 1000 mesh.

[0042] The preparation method of the above-mentioned wear-resistant pen core includes:

[0043] Step 1: First mix the raw materials according to the proportion to form a paste, and extrude it into a blank with an extrusion strength of 500MPa;

[0044] Step 2: preheating the blank under vacuum conditions, the preheating temperature is 400°C, and then calcining at 900°C under the protection of nitrogen;

[0045] Step 3: Process the calcined material to obtain a rough material for the wear-resistant pen core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com