Organic bentonite modified high-strength high-heat-resistance epoxy molding compound for semiconductor packaging and preparation method thereof

An epoxy molding compound, semiconductor technology, applied in the directions of epoxy resin glue, non-polymer adhesive additives, adhesive types, etc., can solve problems such as high cost, and achieve low cost, high reliability, and motion resistance. intensified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

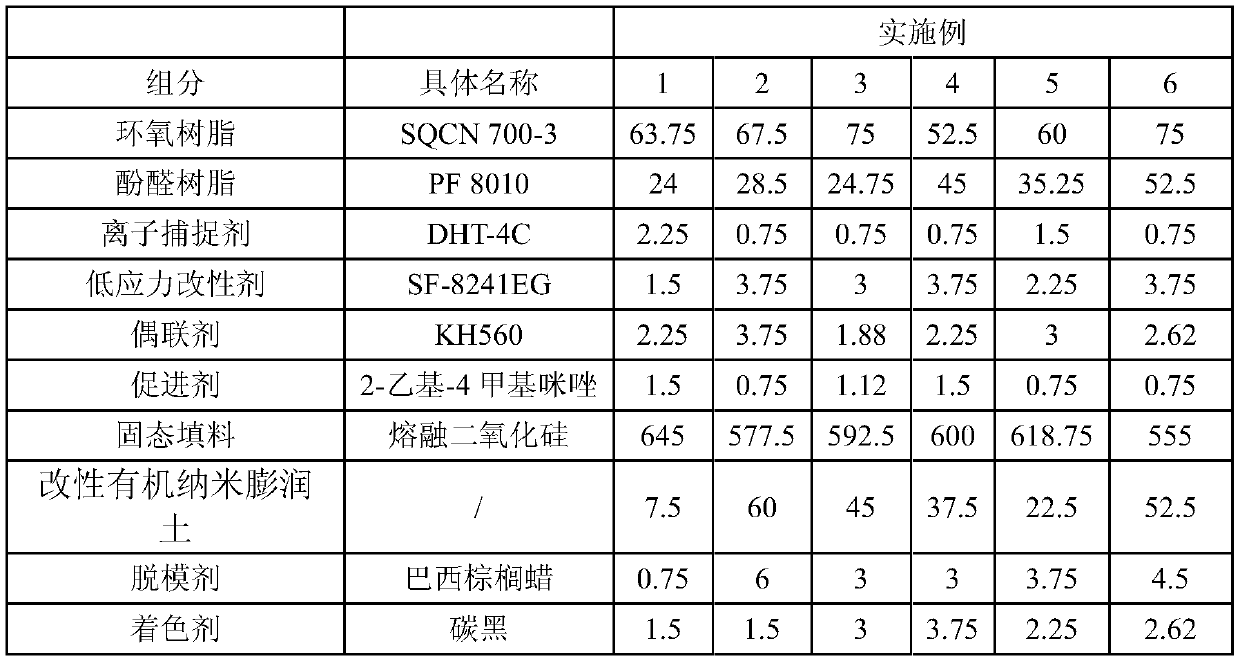

[0087] See Table 1 for the composition of the raw material formulation of the high-strength, high-heat-resistant epoxy molding compound for organic bentonite modified semiconductor packaging in Example 1.

[0088] In this embodiment, the method for preparing organic bentonite modified semiconductor packaging with high strength and high heat-resistant epoxy molding compound is as follows:

[0089] (1) Melt 127.5g of epoxy resin SQCN 700-3 and 15g of modified organic nano-bentonite at a high temperature of 130°C, fully stir for 30min, mix well, cool, pulverize, and sieve for use.

[0090] (2) 71.25g epoxy resin and modified organic nano-bentonite mixture, 24g phenolic resin PF 8010, 2.25g ion trapping agent DHT-4C, 1.5g low stress modifier SF-8241EG, 2.25g coupling agent KH560, 1.5g accelerator 2-ethyl-4 methylimidazole, 645g fused silica, 0.75g release agent carnauba wax and 1.5g colorant carbon black were put into a high-speed mixer and mixed for 5min, and the epoxy molding co...

Embodiment 2

[0093] See Table 1 for the raw material formulation composition of the organobentonite-modified semiconductor packaging high-strength and high-heat-resistant epoxy molding compound in Example 2.

[0094] In this embodiment, the method for preparing organic bentonite modified semiconductor packaging with high strength and high heat-resistant epoxy molding compound is as follows:

[0095] (1) Melt 135g of epoxy resin SQCN 700-3 and 120g of modified organic nano-bentonite at a high temperature of 180°C, fully stir for 90min, mix well, cool, pulverize, and sieve for use.

[0096] (2) 127.5g epoxy resin and modified organic nano-bentonite mixture, 28.5g phenolic resin PF 8010, 0.75g ion trapping agent DHT-4C, 3.75g low stress modifier SF-8241EG, 3.75g coupling agent KH560 , 0.75g accelerator 2-ethyl-4 methylimidazole, 577.5g fused silica, 6g release agent carnauba wax, and 1.5g coloring agent carbon black were dropped into a high-speed mixer and mixed for 5min, and the discharge ob...

Embodiment 3

[0099] See Table 1 for the composition of raw materials of the high-strength, high-heat-resistant epoxy molding compound for organic bentonite modified semiconductor packaging in Example 3.

[0100] In this embodiment, the method for preparing organic bentonite modified semiconductor packaging with high strength and high heat-resistant epoxy molding compound is as follows:

[0101] (1) Melt 150g of epoxy resin SQCN 700-3 and 90g of modified organic nano-bentonite at a high temperature of 160°C, fully stir for 60min, mix well, cool, pulverize, and sieve for use.

[0102] (2) 120g epoxy resin and modified organic nano-bentonite mixture, 24.75g phenolic resin PF 8010, 0.75g ion trapping agent DHT-4C, 3g low stress modifier SF-8241EG, 1.88g coupling agent KH560, 1.12 g accelerator 2-ethyl-4 methylimidazole, 592.5g fused silica, 3g release agent carnauba wax, and 3g colorant carbon black were put into a high-speed mixer and mixed for 5 minutes, and the epoxy molding compound mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com