Method for detecting chloroform in sulfur-containing quantum dot solution

A quantum dot solution and quantum dot technology, which are applied in measurement devices, chemical method analysis, instruments, etc., can solve the problems of cumbersome preparation process, high price, and inability to accurately know when the impurity removal is completed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

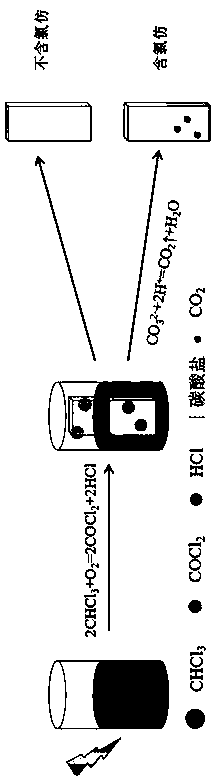

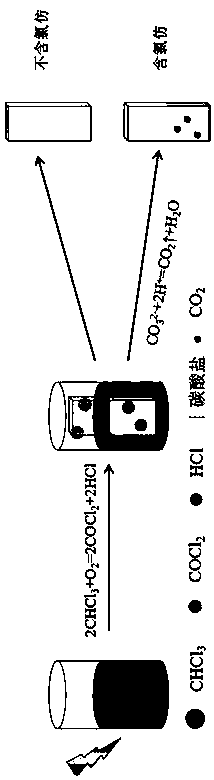

Image

Examples

preparation example Construction

[0027] In this embodiment, the preparation method of the glass whose surface is covered with a carbonate film comprises the steps of: providing a carbonate sol; spin-coating the carbonate sol on the surface of the glass by spin-coating method, so that the carbon The salt sol is evenly spread on the surface of the glass to form a film, and the glass is dried to obtain a glass covered with a carbonate film.

[0028] Preferably, the glass is sequentially placed in acetone, ethanol and water for ultrasonic treatment for 20 minutes to obtain cleaned glass, then the glass is fixed on a spin coater, and the pre-prepared carbonate sol is added dropwise on the On the glass, control the spin coater to rotate at a high speed of 5000-10000r / min for 20 s, so that the carbonate sol is evenly spread into a thin film, placed at room temperature to allow it to dry naturally, and then placed in a vacuum drying oven to dry for 6 h. A glass whose surface is covered with a carbonate film is produc...

Embodiment 1

[0048] Fabrication of surface covered with Ag by spin-coating method 2 CO 3 Thin-film glass and used for qualitative detection and impurity removal of chloroform in sulfur-containing quantum dot solution:

[0049] 1), Ag 2 CO 3 Preparation of the sol: Sonicate the glass in acetone, ethanol, and water for 20 min, and dry it for use; in 50 ml of 2mol / l AgNO 3 Add 0.1 mol sodium lauryl sulfate to the solution, stir for 30 min to fully dissolve, slowly add 50 ml of 1 mol / l Na 2 CO 3 solution, suction filtered, washed with distilled water three times, dried in an oven at 90 degrees Celsius for 12 h, and ground into powder for later use; 10 mg Ag 2 CO 3 Powder and 50 mg 3A molecular sieve were ultrasonically dispersed in 10 ml ethanol, 50 mg PEG6000 was dissolved in 1 ml deionized water, Ag 2 CO 3 Slowly add the ethanol solution, this process is carried out on a magnetic stirrer, stirring at a high speed while heating, and then put the mixed solution in a water bath at 70 de...

Embodiment 2

[0056] Preparation of Ag by Electrospinning2 CO 3 Solid film and used for qualitative detection and impurity removal of chloroform in sulfur-containing quantum dot solution:

[0057] 1) Preparation of silver carbonate sol: Ag 2 CO 3 The preparation method of sol is identical with embodiment 1, promptly in the AgNO of 50 ml 2 mol / l 3 Add 0.1 mol sodium lauryl sulfate to the solution, stir for 30 min to fully dissolve, slowly add 50 ml 1 mol / l Na 2 CO 3 The solution was suction filtered, washed three times with distilled water, dried in an oven at 90°C for 12 h, and ground into powder for later use. 10mg Ag 2 CO 3 and 50 mg 3A molecular sieve were ultrasonically dispersed in 10 ml ethanol, 50 mg PEG6000 was dissolved in 1 ml deionized water, Ag 2 CO 3 The ethanol solution was slowly added to it. This process is carried out on a magnetic stirrer, stirring at a high speed while heating, and then the mixed solution is placed in a water bath at 70 degrees Celsius for 4 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com