RO non-oxidation slime control and sterilization agent, preparation method and applications thereof

A non-oxidizing, fungicide technology, applied in the direction of fungicides, chemical instruments and methods, botany equipment and methods, etc., can solve the problems of shortening the service life of reverse osmosis membranes, economic losses of enterprises, and scrapping of reverse osmosis membranes, etc., to reduce The effect of cleaning and sterilization frequency and cleaning and sterilization time, improving utilization rate and production efficiency, and saving manpower and equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

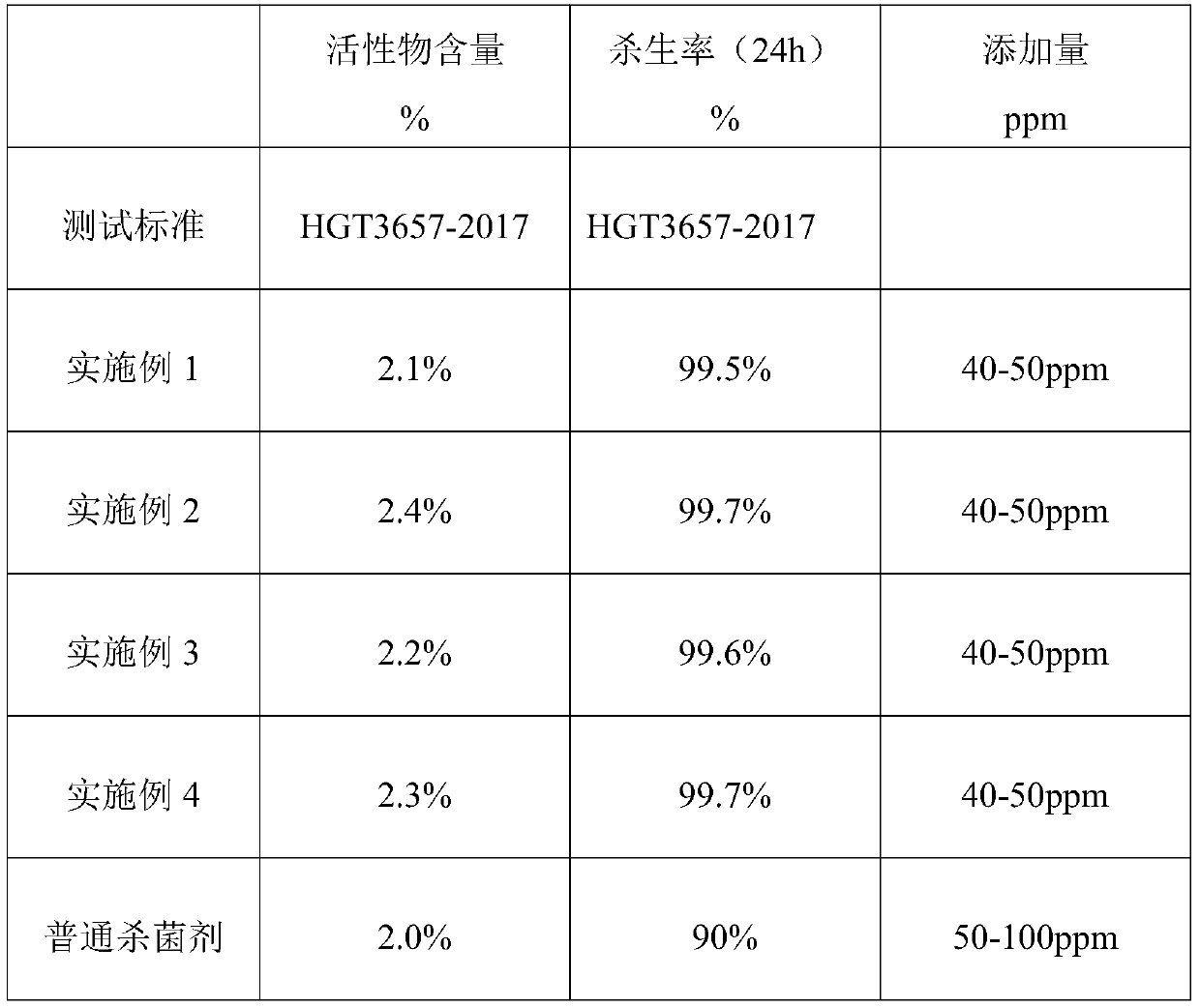

Examples

Embodiment 1

[0052] A RO non-oxidized slime control and bactericide, characterized in that its raw materials include by mass percentage:

[0053] Kasson 13%,

[0054] Bronopol 9.5%,

[0056] Potassium chloride 16%,

[0057] The rest is deionized water, and the total mass percentage of all raw materials is 100%.

[0058] In this embodiment, the Casson is Casson DL102.

[0059] In this embodiment, the sodium chloride is food grade sodium chloride.

[0060] In this embodiment, the potassium chloride is food grade potassium chloride.

[0061] In this embodiment, the RO non-oxidized slime control and preparation method of a bactericide is characterized in that it includes the following steps:

[0062] A. According to the raw material composition of the RO non-oxidized slime control and fungicide, weigh the corresponding raw materials for use;

[0063] B. Add the weighed deionized water, cassone, bronopol, sodium chloride, and potassium chloride in sequence;

[0064] C. Stir evenly...

Embodiment 2

[0067] A RO non-oxidized slime control and bactericide, characterized in that its raw materials include by mass percentage:

[0068] Casson 17%,

[0069] Bronopol 6.5%,

[0070] Sodium chloride 4%,

[0071] Potassium chloride 12%,

[0072] The rest is deionized water, and the total mass percentage of all raw materials is 100%.

[0073] In this embodiment, the Casson is Casson DL102.

[0074] In this embodiment, the sodium chloride is food grade sodium chloride.

[0075] In this embodiment, the potassium chloride is food grade potassium chloride.

[0076] In this embodiment, the RO non-oxidized slime control and preparation method of a bactericide is characterized in that it includes the following steps:

[0077] A. According to the raw material composition of the RO non-oxidized slime control and fungicide, weigh the corresponding raw materials for use;

[0078] B. Add the weighed deionized water, cassone, bronopol, sodium chloride, and potassium chloride in sequence;

[0079] C. Stir evenly, ...

Embodiment 3

[0082] A RO non-oxidized slime control and bactericide, characterized in that its raw materials include by mass percentage:

[0083] Casson 15%,

[0084] Bronopol 8%,

[0085] Sodium chloride 3.2%,

[0086] Potassium chloride 14%,

[0087] The rest is deionized water, and the total mass percentage of all raw materials is 100%.

[0088] In this embodiment, the Casson is Casson DL102.

[0089] In this embodiment, the sodium chloride is food grade sodium chloride.

[0090] In this embodiment, the potassium chloride is food grade potassium chloride.

[0091] In this embodiment, the RO non-oxidized slime control and preparation method of a bactericide is characterized in that it includes the following steps:

[0092] A. According to the raw material composition of the RO non-oxidized slime control and fungicide, weigh the corresponding raw materials for use;

[0093] B. Add the weighed deionized water, cassone, bronopol, sodium chloride, and potassium chloride in sequence;

[0094] C. Stir evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com