Brick with temperature for porcelain brick kiln, and preparation method and application thereof

A ceramic tile, temperature-controlled technology, applied in the field of ceramic tiles, can solve the problems of short service life, easy breakage, unfavorable stability of the kiln system, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

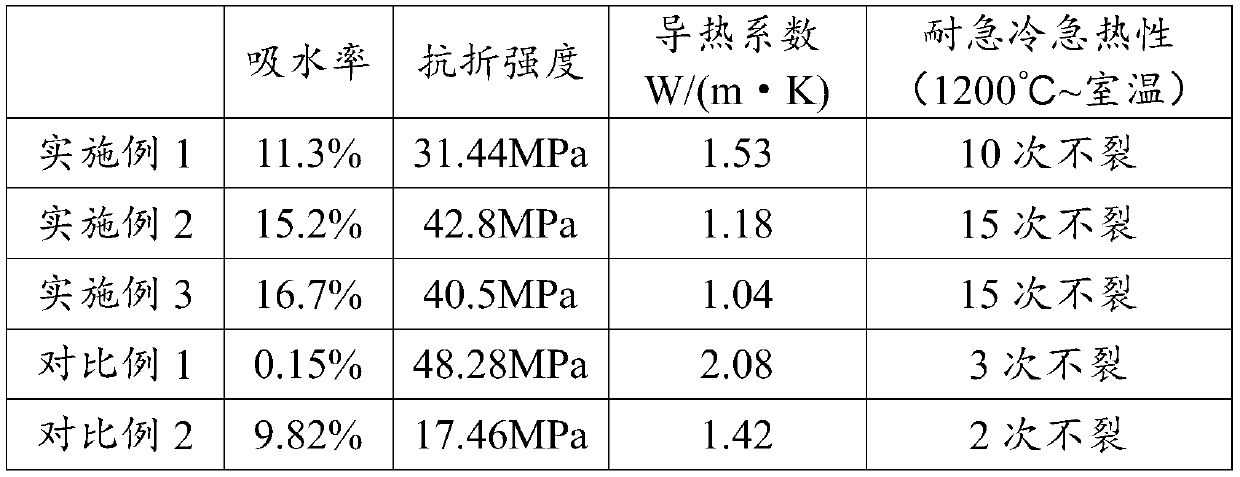

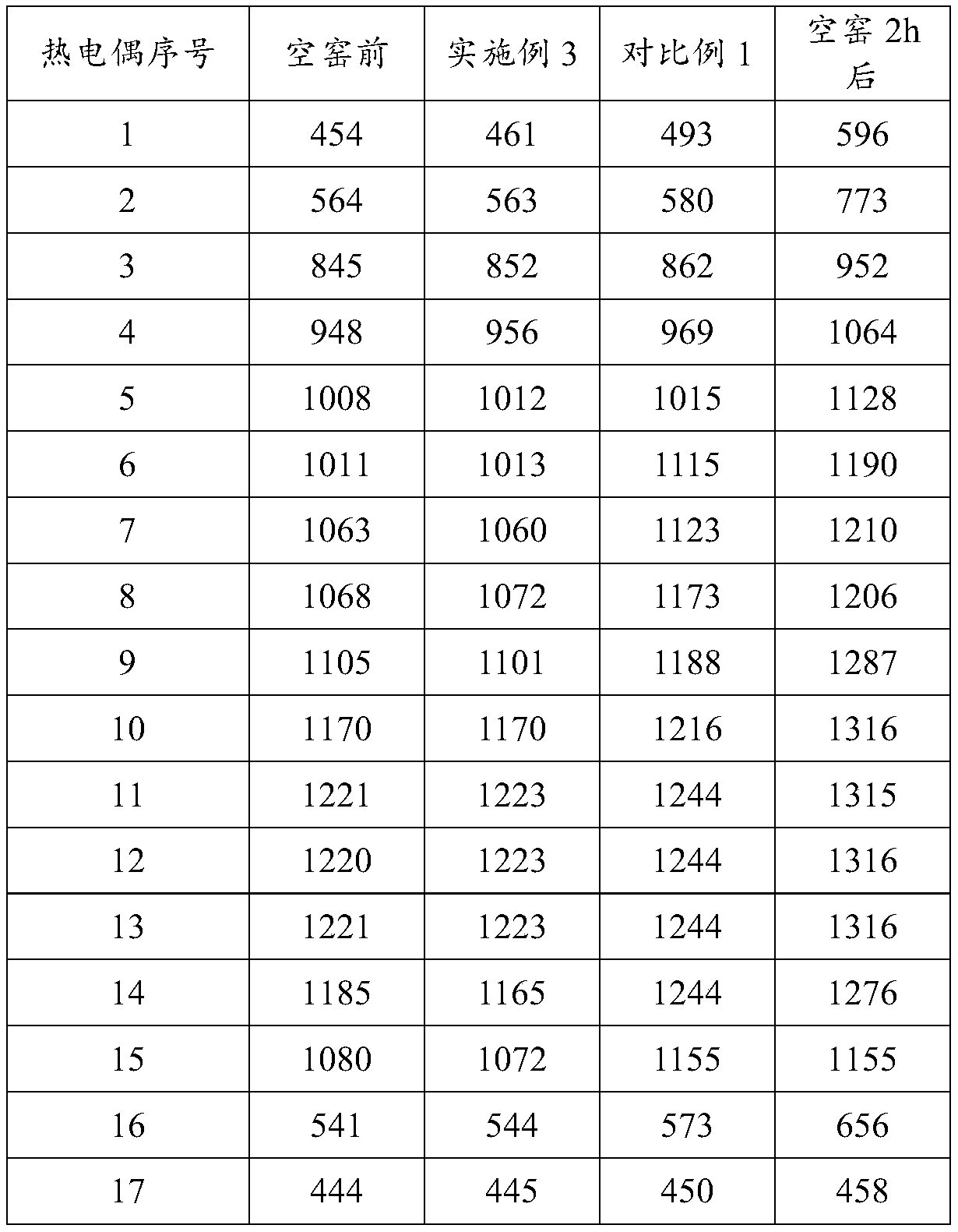

Examples

preparation example Construction

[0045] Correspondingly, the present invention also discloses a method for preparing the above-mentioned heated brick for a porcelain brick kiln, which includes:

[0046] (1) Mix 5-10 parts of roller bar waste, 10-25 parts of magnesia soil, 10-20 parts of bentonite, and 5-15 parts of potassium sodium sand to obtain the first mixture;

[0047] The particle size of roller bar waste and potassium sodium sand is relatively large (>3cm); magnesia soil and bentonite contain some larger soil and / or mud lumps; therefore, these components are firstly mixed and ball milled to promote crushing efficiency. ,

[0048] (2) Mix 1-5 parts of polished brick waste residue, 30-40 parts of fly ash, and 0.5-1.5 parts of binder to obtain a second mixture;

[0049] Polished brick waste slag is the waste slag produced during the polishing process of polished bricks, and its particle size is very small, below 200 mesh (74 μm); fly ash is a product of coal combustion, and its particle size is also sma...

Embodiment 1

[0064] The present embodiment provides a kind of warm brick that is used for porcelain brick kiln, and its formula is:

[0065] 5 parts of roller bar waste, 20 parts of magnesia soil, 18 parts of bentonite, 3 parts of polished brick waste residue, 40 parts of fly ash, 14 parts of potassium sodium sand; 1 part of lignin;

[0066] Among them, the Al 2 o 3 The content is 67.5wt%; the content of MgO in magnesia soil is 21.8wt%, SiO 2 The content is 67.3wt%, Al 2 o 3 The content of Al in fly ash is 2.5wt%; 2 o 3 The CaO content is 34.28wt%, and the CaO content is 5.4wt%.

[0067] The preparation method is:

[0068] (1) mixing the roller bar waste, magnesia soil, bentonite, potassium sodium sand evenly to obtain the first mixture;

[0069] (2) mixing the polished brick waste slag, fly ash and binding agent to obtain the second mixture;

[0070] (3) After ball milling the first mixture for 6 hours, add the second mixture, and continue ball milling for 0.5 hours to obtain a s...

Embodiment 2

[0078] The present embodiment provides a kind of warm brick that is used for porcelain brick kiln, and its formula is:

[0079] 8 parts of roller bar waste, 24 parts of magnesia soil, 15 parts of bentonite, 5 parts of polished brick waste residue, 38 parts of fly ash, 10 parts of potassium sodium sand; 1.2 parts of sodium carboxymethyl cellulose;

[0080] Among them, the Al 2 o 3 The content is 58.6wt%; the content of MgO in magnesia soil is 23.2wt%, SiO 2 The content is 65.9wt%, Al 2 o 3 The content of Al in fly ash is 1.6wt%; 2 o 3 The CaO content is 31.7wt%, and the CaO content is 12.4wt%.

[0081] The preparation method is:

[0082] (1) mixing the roller bar waste, magnesia soil, bentonite, potassium sodium sand evenly to obtain the first mixture;

[0083] (2) mixing the polished brick waste slag, fly ash and binding agent to obtain the second mixture;

[0084] (3) After ball milling the first mixture for 7 hours, add the second mixture, and continue ball milling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Average thermal conductivity | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com