Waterborne polyurethane resin and preparation method thereof, and application of waterborne polyurethane resin in digital ink-jet printing ink

A water-based polyurethane and resin technology, applied in applications, inks, dyeing methods, etc., can solve the problems of large particle size, easy to block the nozzle, difficult to meet the requirements of digital inkjet printing ink, etc., and achieve the effect of simple steps and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides the preparation method of waterborne polyurethane resin described in above-mentioned scheme, comprises the following steps:

[0040] (1) Part of the organic solvent, polyol, catalyst and aliphatic diisocyanate are mixed for the first reaction to obtain the first reaction liquid;

[0041] (2) Mixing the first reaction solution, internal emulsifier, end-capping agent and remaining organic solvent for a second reaction to obtain a prepolymer;

[0042] (3) mixing the prepolymer, water and chain extender for a third reaction to obtain a third reaction solution;

[0043] (4) removing the organic solvent in the third reaction solution and then filtering to obtain a water-based polyurethane resin.

[0044] In the present invention, part of the organic solvent, polyol, catalyst and aliphatic diisocyanate are mixed for the first reaction to obtain the first reaction liquid. In the present invention, the temperature of the first reaction is prefera...

Embodiment 1

[0059] (1) Introduce nitrogen into a dry and clean four-neck flask equipped with a stirring and condensing reflux device, and sequentially add 180 g of acetone, 283 g of polyglycol Desmophene C1200, and 10 g of tetrabutyl titanate into the flask, stir evenly and heat , the stirring speed is 300 rpm, and the temperature is controlled at 40°C.

[0060] (2) Add 135g of IPDI into the reaction bottle for reaction, adopt the method of slow dropwise addition, and use a peristaltic pump to slowly and evenly add, the adding time is 60-90min, and the temperature is controlled at 40°C during this process. Then heated to 50°C, uniformly stirred for 30min, and the stirring speed was 300rpm.

[0061] (3) Dissolve 28.3g of DMPA in a mixture of 8g of TEA and 20g of acetone, then add it into the reaction flask with a peristaltic pump, finish adding in 10 minutes, and react at 50°C with a stirring speed of 300rpm until the isocyanate group (%NCO) concentration is lower than 1.2%, the reaction ...

Embodiment 2

[0065] (1) Feed nitrogen into a dry, clean four-necked flask with a stirring and condensing reflux device, and successively add 90 g of methyl ethyl ketone, polyglycol Nippollan981R 115 g, and 1 g of dibutyltin dilaurate into the flask to stir evenly and Heating, the stirring speed is 400rpm, and the temperature is controlled at 55°C.

[0066] (2) Add 70g of HDI into the reaction flask for reaction, and use the slow drop method to add slowly and evenly with a peristaltic pump. The adding time is 60-90min, and the temperature is controlled at 55°C during this process. Then heated to 65°C and stirred uniformly for 40min at a stirring speed of 400rpm.

[0067](3) Dissolve 10g of DMBA in the mixture of 2g of DEA and 10g of methyl ethyl ketone, then add it into the reaction flask with a peristaltic pump, finish adding in 10 minutes, and react at 65°C with a stirring speed of 300-500rpm until the isocyanide The concentration of acid groups (%NCO) is lower than 1.2%, and the reactio...

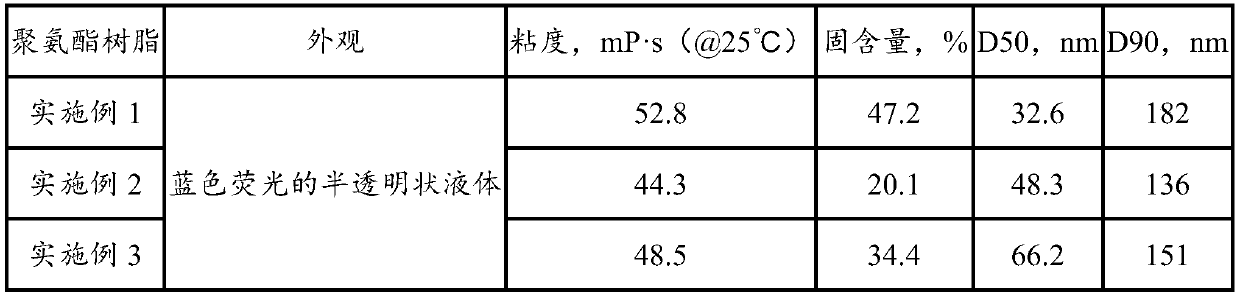

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com