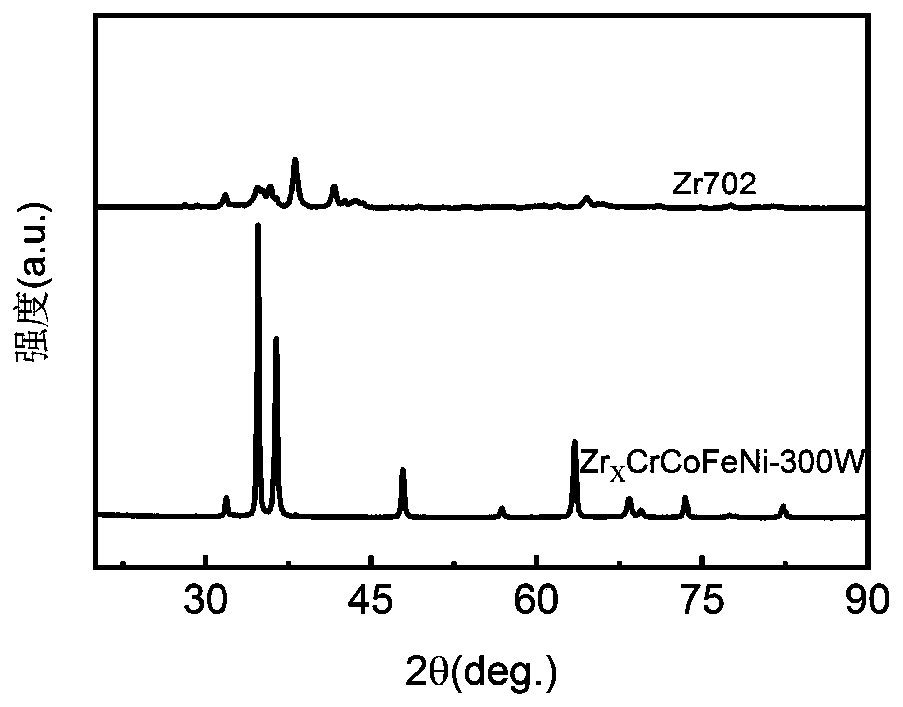

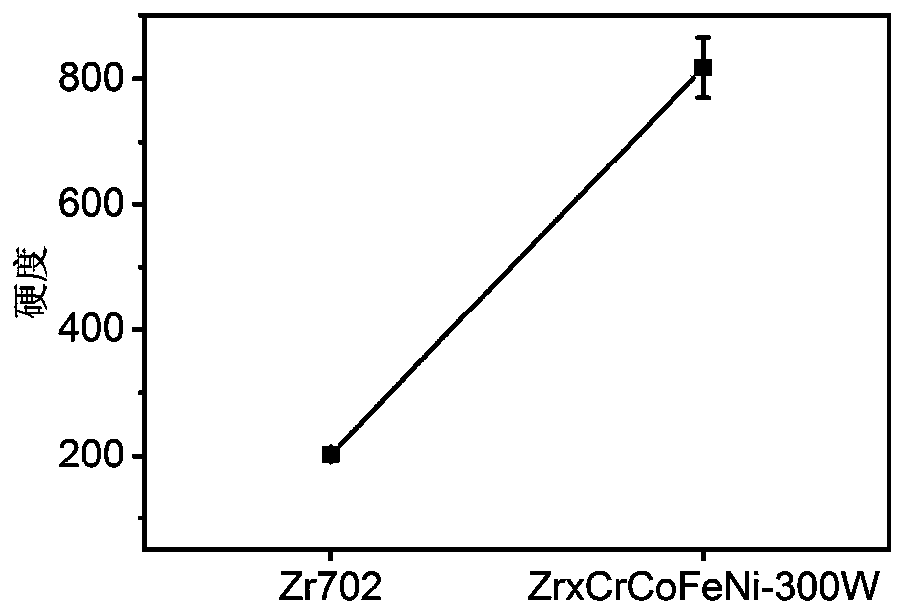

Method for preparing superhard ZrxCrCoFeNi high-entropy alloy coating on surface of zirconium alloy

A high-entropy alloy and zirconium alloy technology, applied in the coating process and coating of metal materials, can solve the problems of uneven composition, high cost, high brittleness, etc., and achieve good ductility, improved hardness and good plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

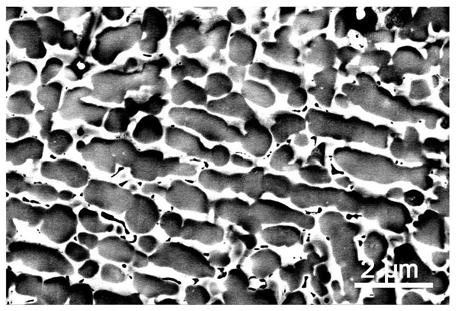

Embodiment 1

[0028] Select the prepared 12×18×2mm Zr702 alloy sample, first use 400#, 800#, 1000#, 1200#, 2000# and 3000# sandpaper to polish the sample until it is bright, and rotate 90° each time the sandpaper sample with different values is changed. °. After the sample was polished, it was cleaned with absolute ethanol, and finally its surface was dried. Place the sample after cleaning the surface on a special carrier, and use PVA organic solvent to mix metal powders composed of Cr, Co, Fe, Ni (Co, Cr, Fe, Ni have the same mole fraction) into a paste , evenly coated on the surface of the workpiece, and then dried in a drying oven. The process parameters of the coating preset treatment are: PVA organic solvent concentration 6wt.%, coating preset thickness 1000-1200μm, drying temperature 120°C, drying Time 8h.

[0029] Clamp the dried sample on a special fixture, put it into the working station of the pulse laser equipment, and use argon with a purity of 99.9% as the shielding gas. S...

Embodiment 2

[0032]Select the prepared 12×18×2mm Zr702 alloy sample, first use 400#, 800#, 1000#, 1200#, 2000# and 3000# sandpaper to polish the sample until it is bright, and rotate 90° each time the sandpaper sample with different values is changed. °. After the sample was polished, it was cleaned with absolute ethanol, and finally its surface was dried. Place the sample after cleaning the surface on a special carrier, and use PVA organic solvent to mix metal powders composed of Cr, Co, Fe, Ni (Co, Cr, Fe, Ni have the same mole fraction) into a paste , evenly coated on the surface of the workpiece, and then dried in a drying oven. The process parameters of the coating preset treatment are: PVA organic solvent concentration 8wt.%, coating preset thickness 1000-1200μm, drying temperature 120°C, drying Time 8h.

[0033] Clamp the dried sample on a special fixture, put it into the working station of the pulse laser equipment, and use argon with a purity of 99.9% as the shielding gas. St...

Embodiment 3

[0036] Select the prepared 12×18×2mm Zr702 alloy sample, first use 400#, 800#, 1000#, 1200#, 2000# and 3000# sandpaper to polish the sample until it is bright, and rotate 90° each time the sandpaper sample with different values is changed. °. After the sample was polished, it was cleaned with absolute ethanol, and finally its surface was dried. Place the sample after cleaning the surface on a special carrier, and use PVA organic solvent to mix metal powders composed of Cr, Co, Fe, Ni (Co, Cr, Fe, Ni have the same mole fraction) into a paste , evenly coated on the surface of the workpiece, and then dried in a drying oven. The process parameters of the coating preset treatment are: PVA organic solvent concentration 10wt.%, coating preset thickness 1000-1200μm, drying temperature 120°C, drying Time 8h.

[0037] Clamp the dried sample on a special fixture, put it into the working station of the pulse laser equipment, and use argon with a purity of 99.9% as the shielding gas. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com