Fluorine-containing wastewater treatment device and process for liquid crystal display panel production plant

A technology for wastewater treatment and liquid crystal panel, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Achieve the effect of low chemical consumption, low risk of scaling and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

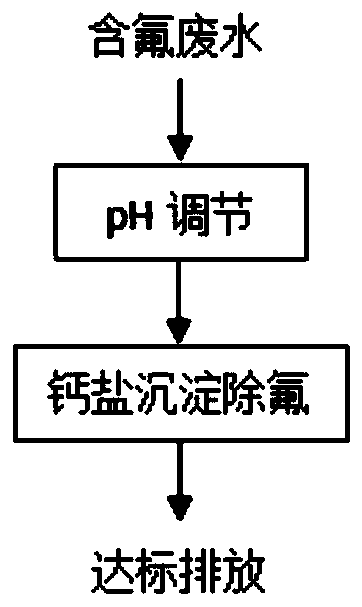

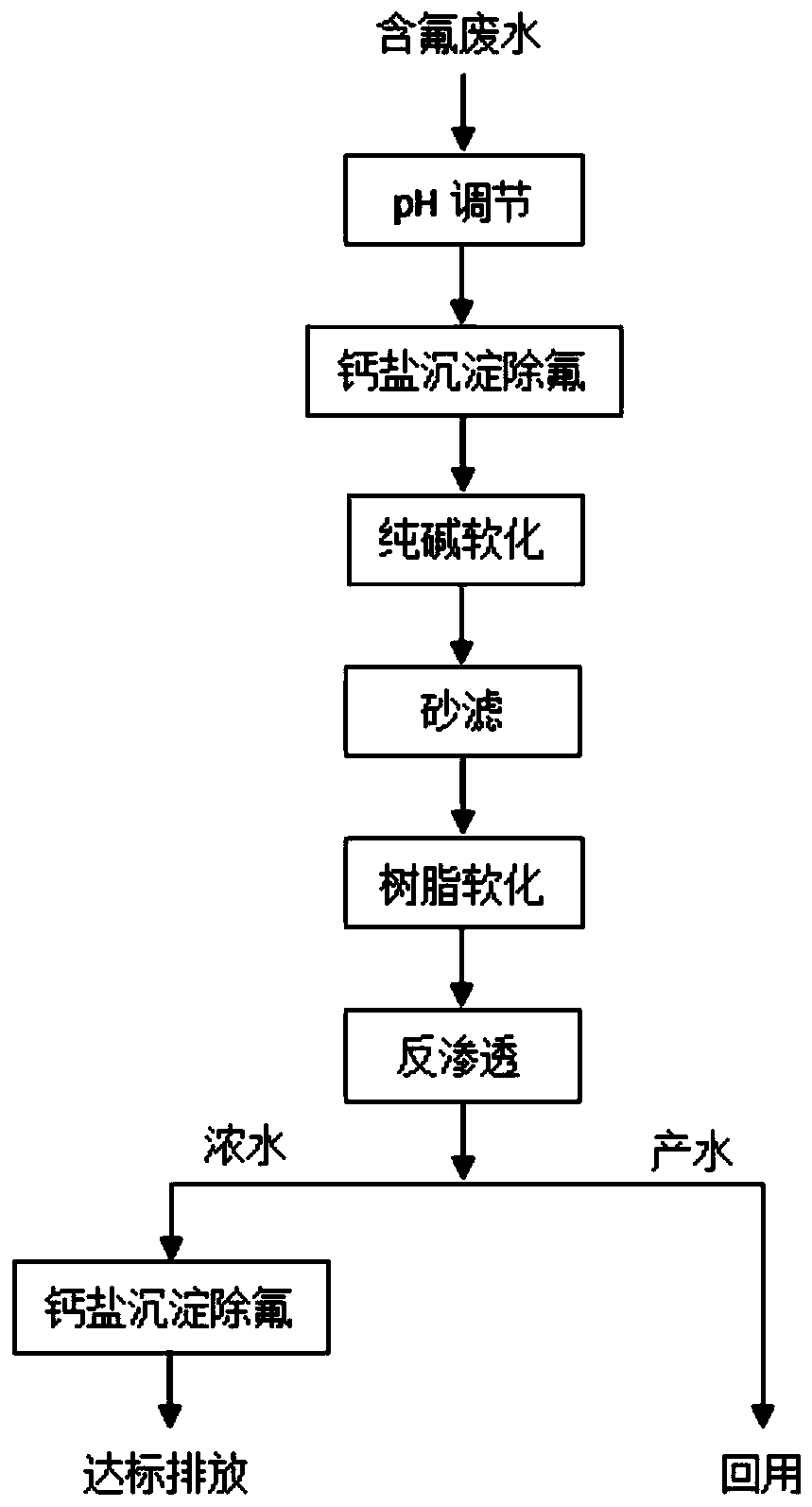

Problems solved by technology

Method used

Image

Examples

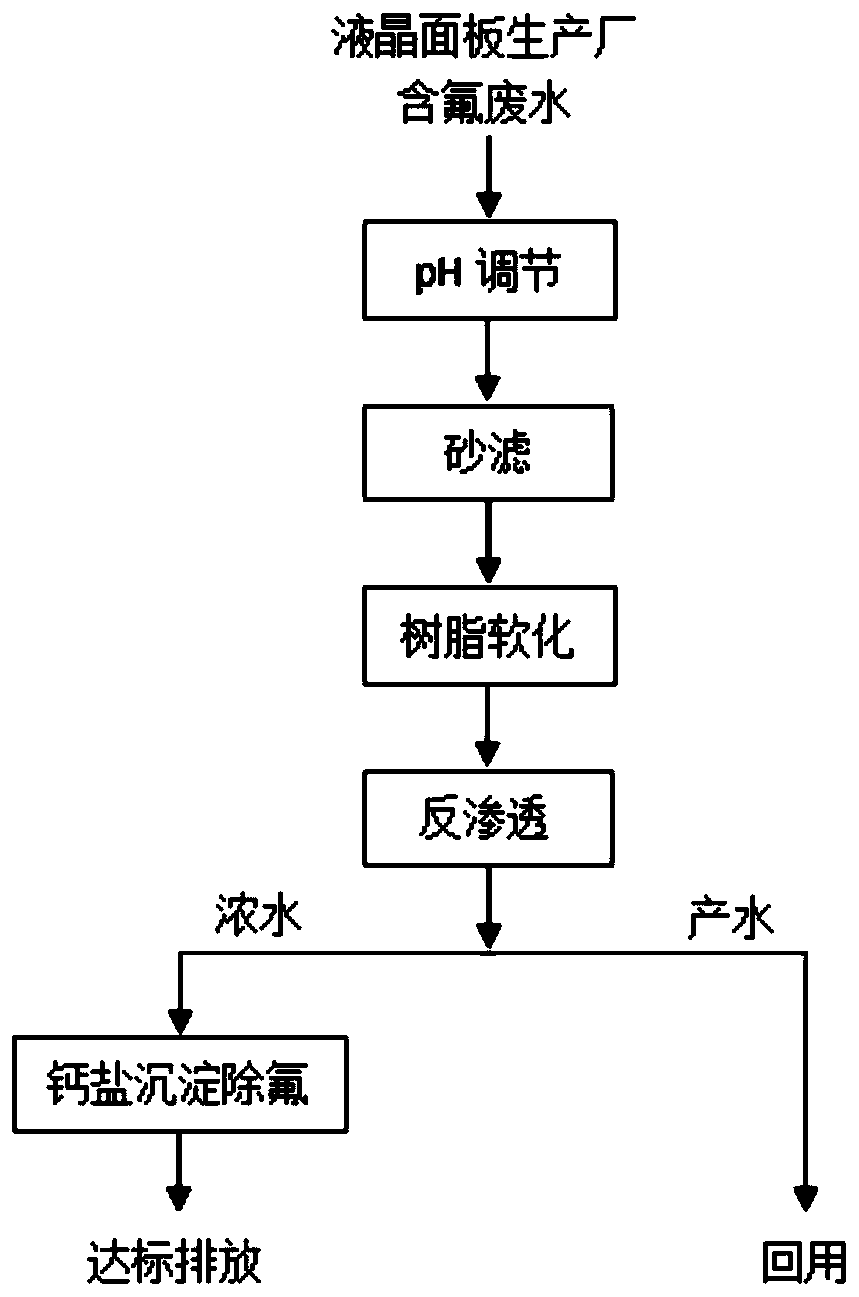

Embodiment 1

[0045] see Figure 5, in an embodiment of the present invention, a liquid crystal panel production plant fluorine-containing wastewater treatment device, including a pH adjustment tank 1, a resin softening tank 3, a reverse osmosis device 6 and a concentrated water chemical precipitation device; the pH adjustment tank 1 and resin softening tank A sand filter 2 is arranged between the tanks 3, and the outlet end of the pH adjustment tank 1 is connected with the inlet end of the sand filter water inlet pump 12 through a pipeline, and the outlet end of the sand filter water inlet pump 12 is connected with the sand filter 2 through a pipeline; The filter 2 is connected with the resin softening tank 3 through a pipeline, and the resin softening tank 3 is connected with an intermediate water tank 4 through a pipeline; The outlet end of the pump is connected with a security filter 5 through a pipeline; the security filter 5 is connected with the inlet end of the reverse osmosis high ...

Embodiment 2

[0054] The embodiment of the present invention provides a fluorine-containing wastewater treatment process based on the device described in Example 1. This embodiment takes the treatment of fluorine-containing wastewater in a liquid crystal panel production plant as an example. The water quality parameters of the fluorine-containing wastewater in this factory are shown in the following table :

[0055] Water quality project unit value Fluoride mg / L 19.9-184 pH value - 4-6.5 total hardness mg / L, CaCO 3 count

0.4-27 Conductivity μS / cm 171-1255 water temperature ℃ 20-24

[0056] Table 1 Water quality parameters of fluorine-containing wastewater in a LCD panel production plant

[0057] The specific treatment process is as follows:

[0058] 1) The fluorine-containing wastewater flows into the pH adjustment tank, and NaOH is added to the pH adjustment tank, and the pH adjustment tank mixer is fully mixed with the wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com