High-efficiency PERC solar cell and preparation method thereof

A technology of solar cells and solar cells, which is applied in the field of solar cells, can solve the problems of affecting the power level of solar cells and less research on CID coping strategies, and achieve the effects of improving conversion efficiency, increasing the absolute value of efficiency, and reducing CID decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

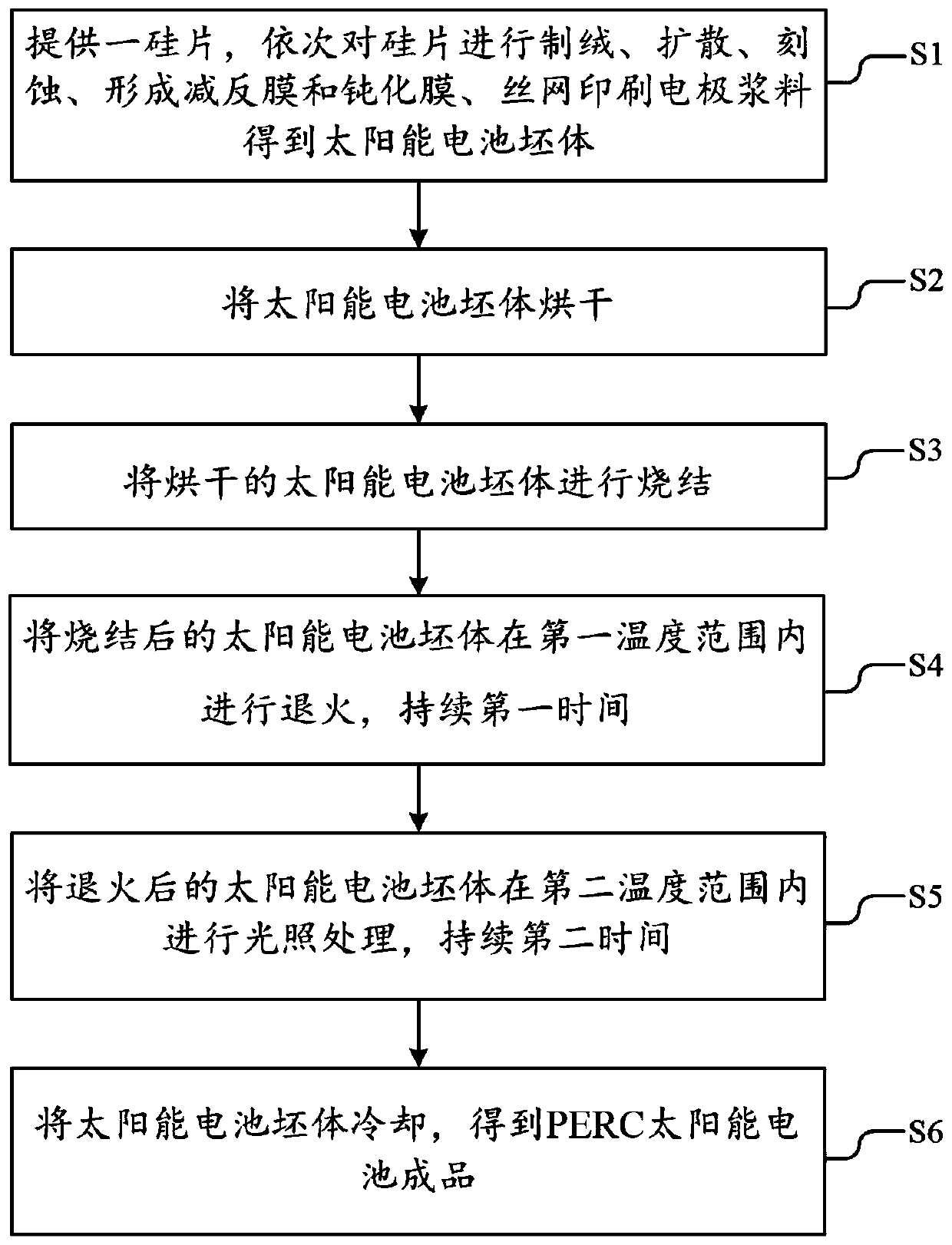

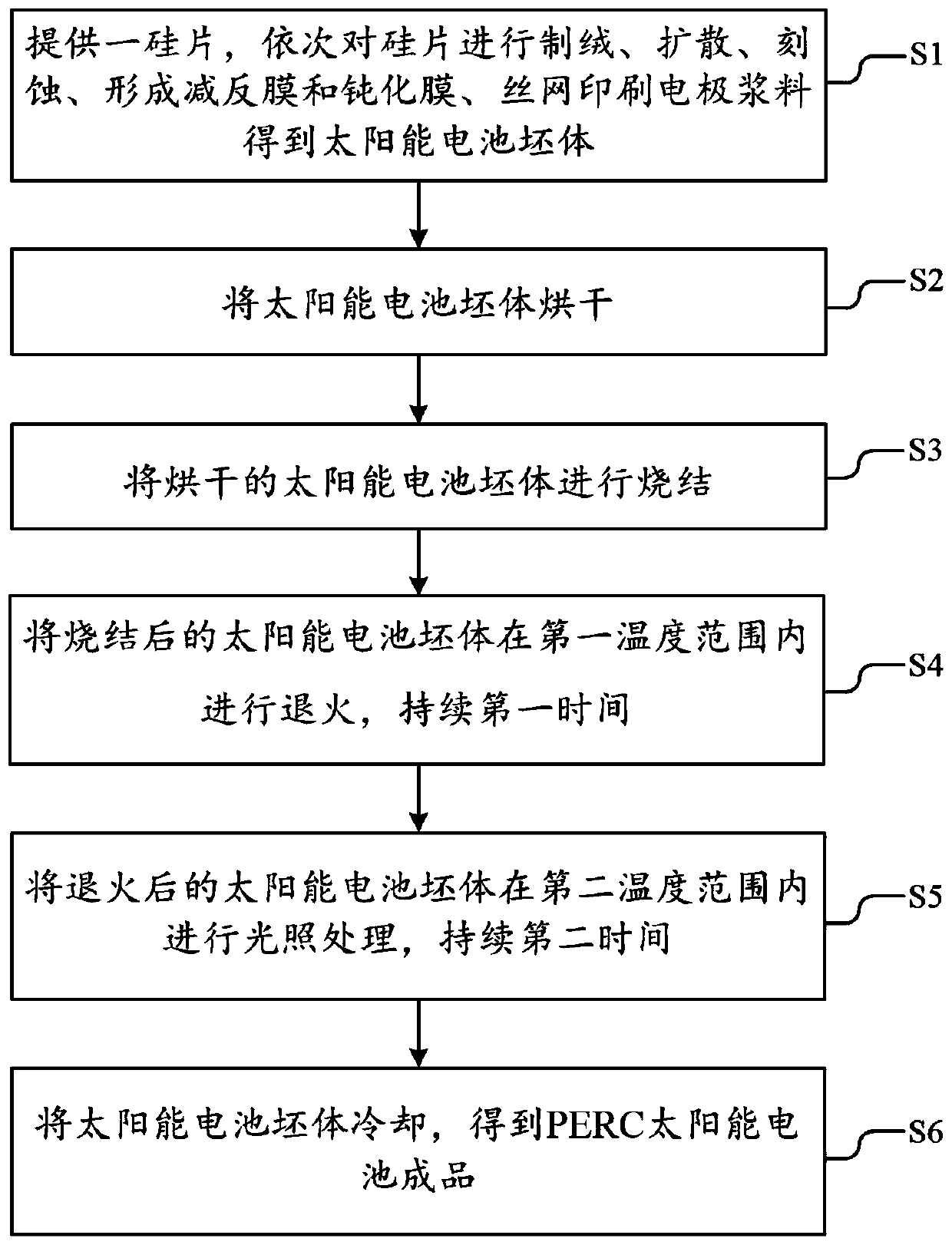

[0048] The present invention provides a method for preparing a high-efficiency PERC solar cell, referring to figure 1 , which includes the following steps:

[0049] S1: Provide a silicon wafer, perform texturing, diffusion, etching, formation of anti-reflection film and passivation film, and screen printing electrode paste on the silicon wafer in sequence to obtain a solar cell body;

[0050] Specifically, S1 includes:

[0051] S11 provides a silicon wafer, and forms a suede surface on the silicon wafer;

[0052] The silicon chip can be selected from P-type silicon or N-type silicon; the silicon chip is cleaned and polished before texturing, and then corroded for texturing;

[0053] S12: Perform high-resistance diffusion on the front side of the silicon wafer to form a PN junction;

[0054] S13: Perform selective laser doping on the front side of the silicon wafer;

[0055] S14: Etching to remove the by-products and surrounding PN junctions formed during the diffusion proc...

Embodiment 1

[0108] This embodiment provides a method for preparing a high-efficiency PERC solar cell, which includes:

[0109] (1) providing a silicon wafer, performing texturing, diffusion, etching, forming an anti-reflection film and a passivation film, and screen-printing electrode paste on the silicon wafer in sequence to obtain a solar cell body;

[0110] (2) drying the solar cell green body;

[0111] Specifically, the drying temperature curve is: 160°C-200°C-240°C-280°C, and the drying time is 40s;

[0112] (3) Sintering the dried solar cell green body;

[0113] Specifically, during the sintering process, the temperature curve is set at 650°C-750°C-850°C-950°C; the sintering time is 30s;

[0114] (4) annealing the sintered solar cell body in a first temperature range for a first time;

[0115] Specifically, during the annealing process, the temperature curve is set at 700°C-600°C-500°C-400°C; the processing time is 90s;

[0116] (5) performing light treatment on the annealed sol...

Embodiment 2

[0121] This embodiment provides a method for preparing a high-efficiency PERC solar cell, which includes:

[0122] (1) providing a silicon wafer, performing texturing, diffusion, etching, forming an anti-reflection film and a passivation film, and screen-printing electrode paste on the silicon wafer in sequence to obtain a solar cell body;

[0123] (2) drying the solar cell green body;

[0124] Specifically, the drying temperature curve is: 260°C-280°C-320°C-360°C, and the drying time is 25s;

[0125] (3) Sintering the dried solar cell green body;

[0126] Specifically, during the sintering process, the temperature curve of the upper surface of the solar cell green body is set to 530°C-630°C-730°C-830°C; the temperature curve of the lower surface is set to: 630°C-730°C-830°C-930°C ℃; sintering time is 30s;

[0127] (4) annealing the sintered solar cell body in a first temperature range for a first time;

[0128] Specifically, during the annealing process, the temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com