Preparation method, product and application of RGO modified sodium vanadium oxyfluorophosphate composite material

A technology for replacing sodium vanadyl phosphate and nanocomposite materials, which is applied in the fields of nanomaterials and electrochemistry, can solve problems such as low Coulomb efficiency, and achieve the effects of simple synthesis process, high specific capacity and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the NVOPF@RGO material provided in this example is: mix 18mmol H 2 C 2 o 4 2H 2 O, 6mmolV 2 o 5 and 50 mL of deionized water were added into a round bottom flask, heated and stirred at 60°C for 2 h to obtain a clear and transparent blue solution. 12mmol NaH 2 PO 4 2H 2 O, 6 mmol NaF and 1 mL GO solution (18.7 mg / mL) were added to the resulting solution and stirred to dissolve. With 2mol / L Na 2 CO 3 The pH value of the solution was adjusted to 3.0, and transferred to a flask for reaction at 120°C for 24 hours. The resulting green precipitate was washed by centrifugation for several times, then suction-filtered, and dried in a vacuum oven at 60°C for 24 hours. The obtained intermediate product was transferred to a tube furnace and heat-treated at 500 °C for 2 h under an argon atmosphere to prepare NVOPF@RGO material.

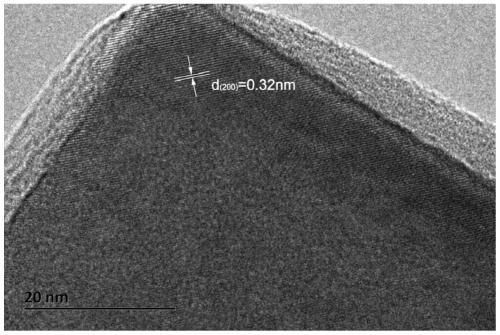

[0048] The TEM image of the NVOPF@RGO material prepared in this example is as follows Figure 4 shown.

Embodiment 2

[0050] The preparation method of the NVOPF@RGO material provided in this example is: mix 18mmol H 2 C 2 o 4 2H 2 O, 6mmolV 2 o 5 and 50 mL of deionized water were added into a round bottom flask, heated and stirred at 60°C for 2 h to obtain a clear and transparent blue solution. 12mmol NaH 2 PO 4 2H 2 O, 6 mmol NaF and 1 mL GO solution (18.7 mg / mL) were added to the resulting solution and stirred to dissolve. With 2mol / L Na 2 CO 3 The pH value of the solution was adjusted to 6.0, and transferred to a flask for reaction at 120°C for 24 hours. The resulting green precipitate was washed by centrifugation for several times, then suction-filtered, and dried in a vacuum oven at 60°C for 24 hours. The obtained intermediate product was transferred to a tube furnace and heat-treated at 500 °C for 2 h under an argon atmosphere to prepare NVOPF@RGO material.

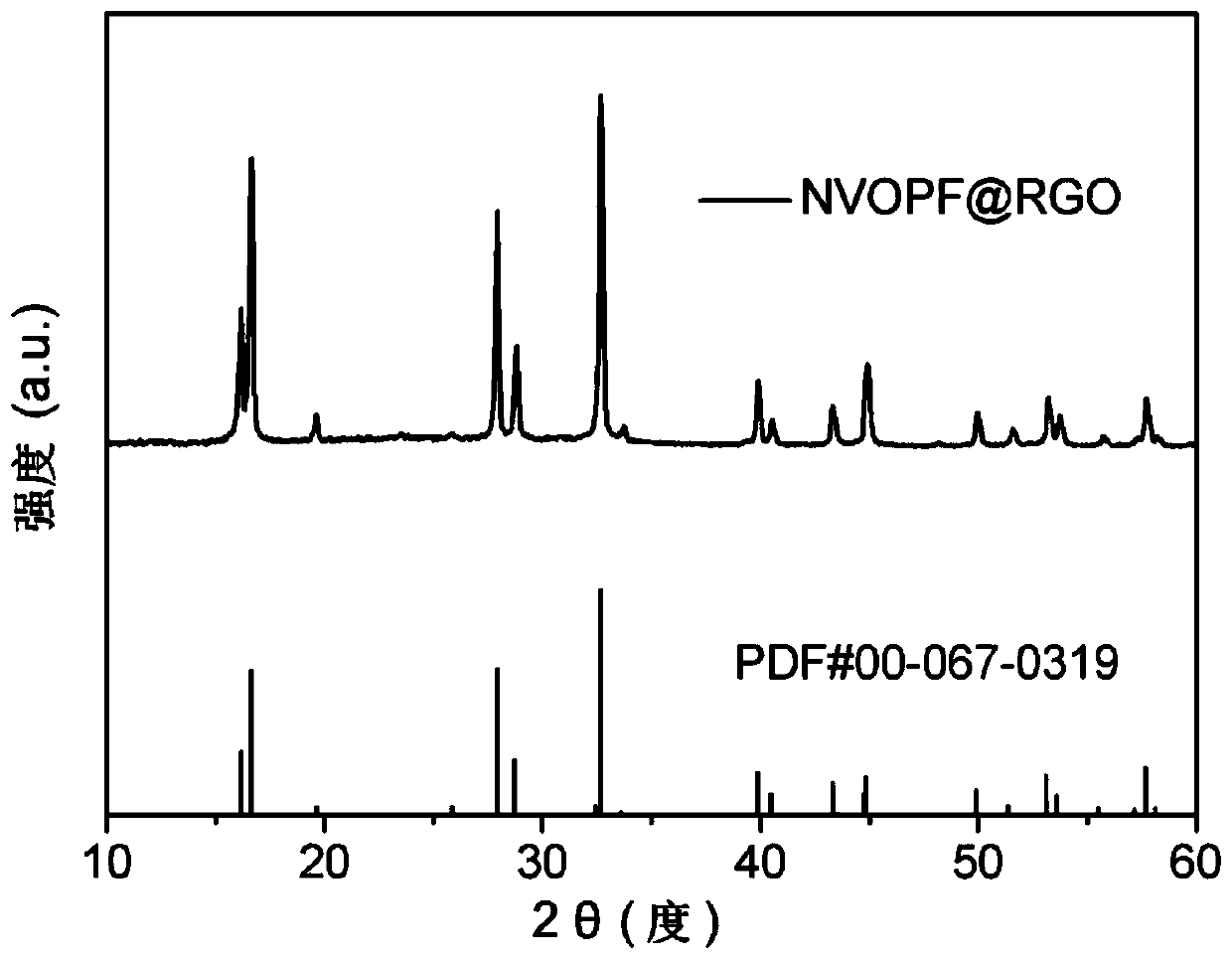

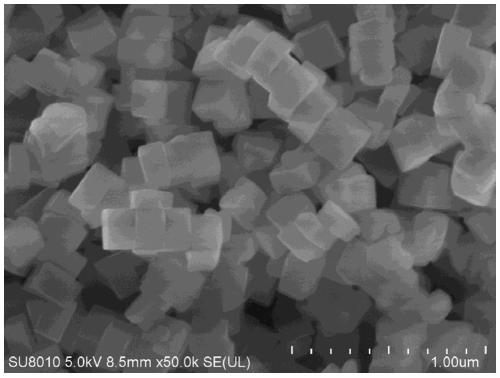

[0051] The XRD diagram, SEM diagram, TEM diagram, HR-TEM diagram, TEM diagram, FTIR diagram, XPS diagram, SSNMR diagra...

Embodiment 3

[0053] 12mmol H 2 C 2 o 4 2H 2 O, 4 mmol V 2 o 5 and 50 mL of deionized water were added into a round bottom flask, heated and stirred at 60°C for 2 h to obtain a clear and transparent blue solution. 8mmol NaH 2 PO 4 2H 2 O, 4 mmol NaF and 1 mL GO solution (18.7 mg / mL) were added to the resulting solution, stirred to dissolve. With 2mol / L Na 2 CO 3 The pH value of the solution was adjusted to 6.0, and transferred to a flask for reaction at 120°C for 24 hours. The resulting green precipitate was washed by centrifugation for several times, then suction-filtered, and dried in a vacuum oven at 60°C for 24 hours. The obtained intermediate product was transferred to a tube furnace and heat-treated at 500 °C for 2 h under an argon atmosphere.

[0054] The TEM image of the NVOPF@RGO material prepared in this example is as follows Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com