Process for forming a powder

A powder, polyolefin technology, applied in the field of powder formation, which can solve the problems of incomplete densification and deterioration of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

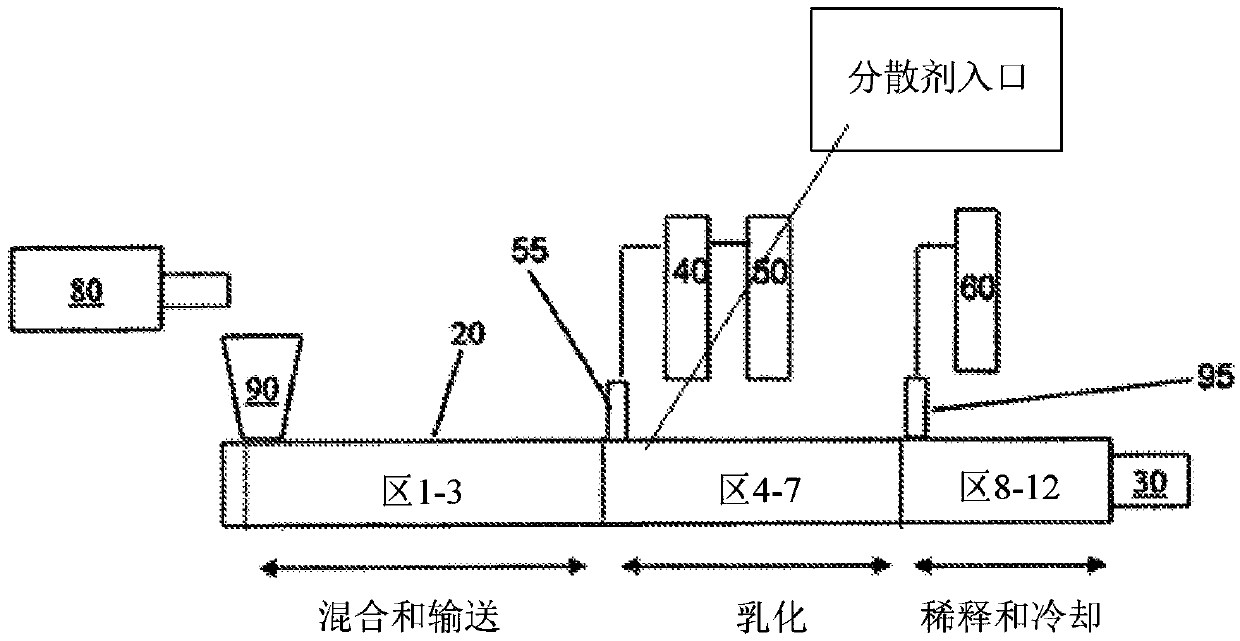

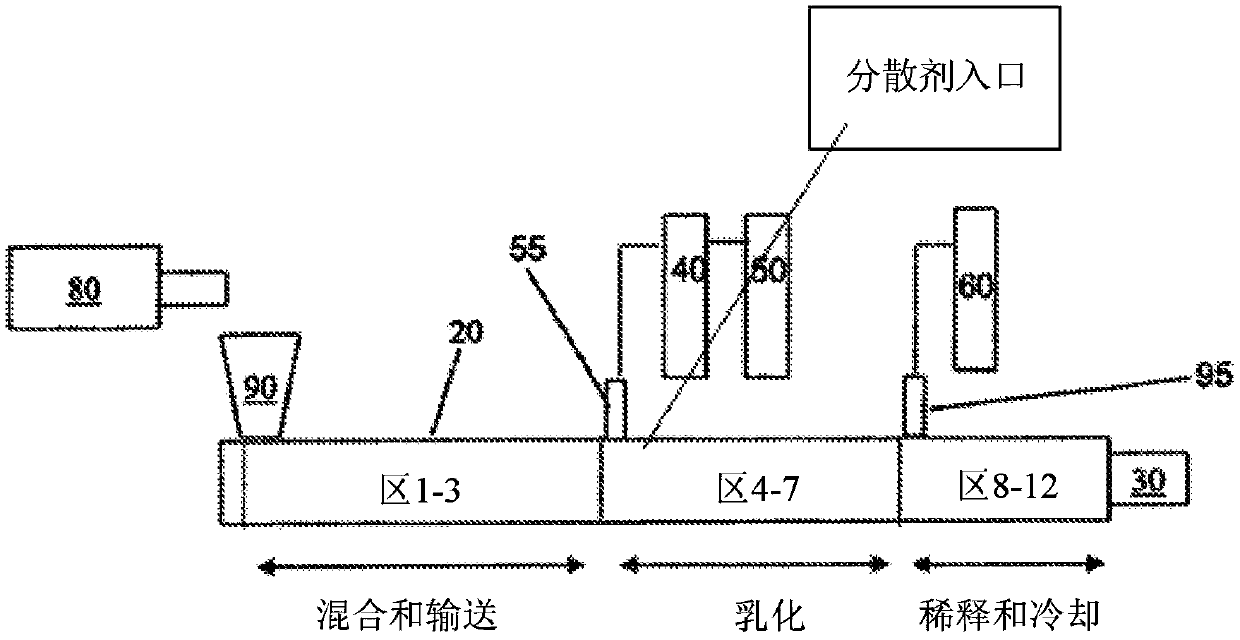

Method used

Image

Examples

example

[0184] Materials used in the examples are provided in Table 1 below.

[0185] Table 1

[0186]

[0187] *Based on total weight of dispersant

[0188] Preparation of Acrylic Dispersant A (AD-A)

[0189] Acrylic Dispersant A (AD-A) was prepared by adding 3210 grams (g) of DI water to a 4 liter (L) 4-neck glass flask equipped with an overhead stirrer, condenser, and connected to A heating mantle set to modulate the kettle lifter's temperature controller. The flask was placed under nitrogen and heated to 80°C. At the same time, by mixing 3107g DI water, 70.1g Aerosol TM A-102 surfactant (disodium ethoxylated alcohol (C10-12) sulfosuccinate half ester, available from CYTEC Industries Inc.), 165.1 g FES-32 surfactant ( Sodium lauryl ether sulfate, available from BASF Corporation), 6777.1 g 2-ethylhexyl acrylate, 183.2 g methyl methacrylate, and 2198.0 g MAA to build up the monomer emulsion to form a thick white Stabilizes the emulsion. Once the reactor temperature stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com