Co-doped BZCYO photocatalyst as well as preparation method and application thereof

A photocatalyst and chemical formula technology, applied in the field of photocatalysis, can solve the problems that trouble researchers and the efficiency is not very high, and achieve the effect of reducing the recombination rate, increasing the utilization rate, and enhancing the catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

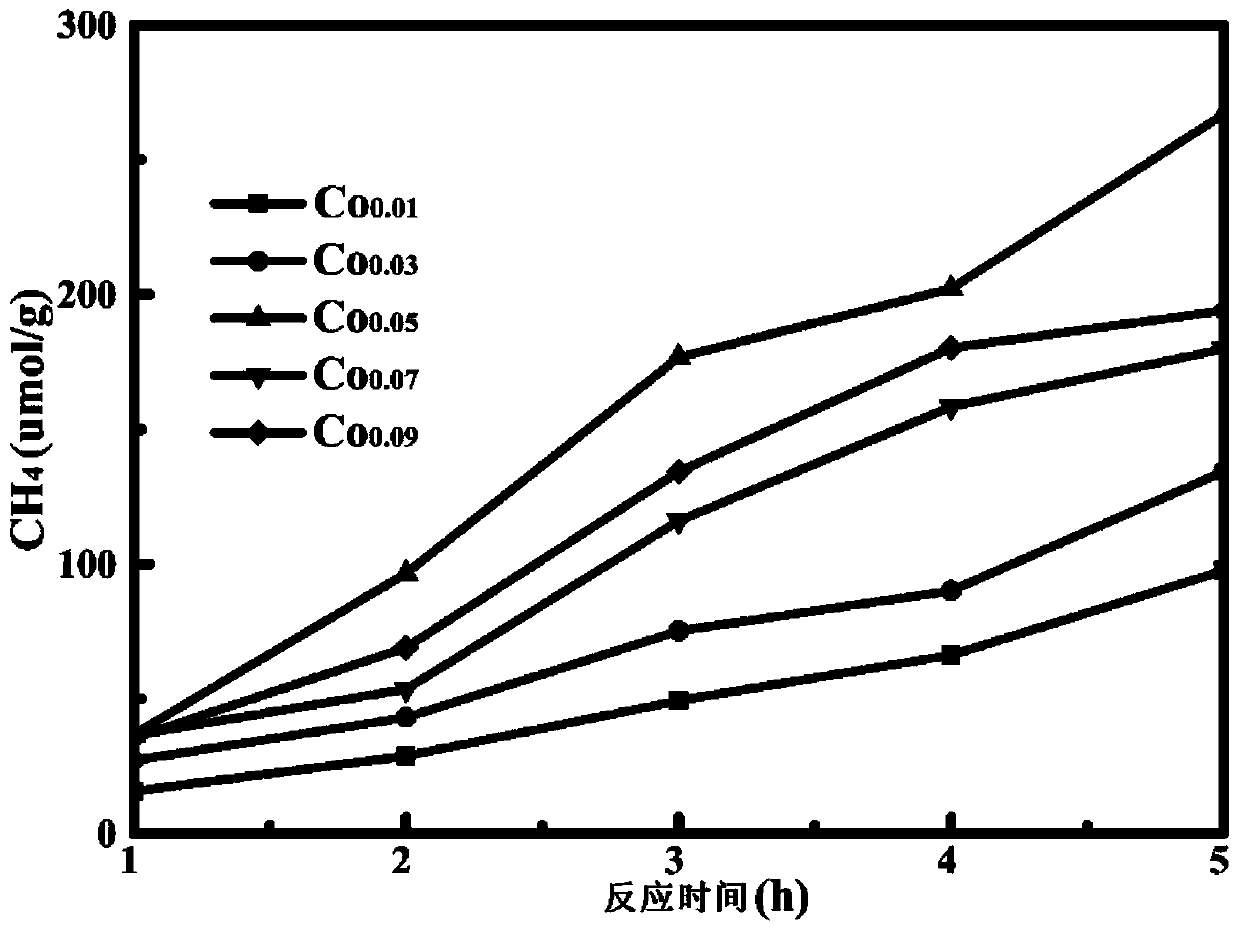

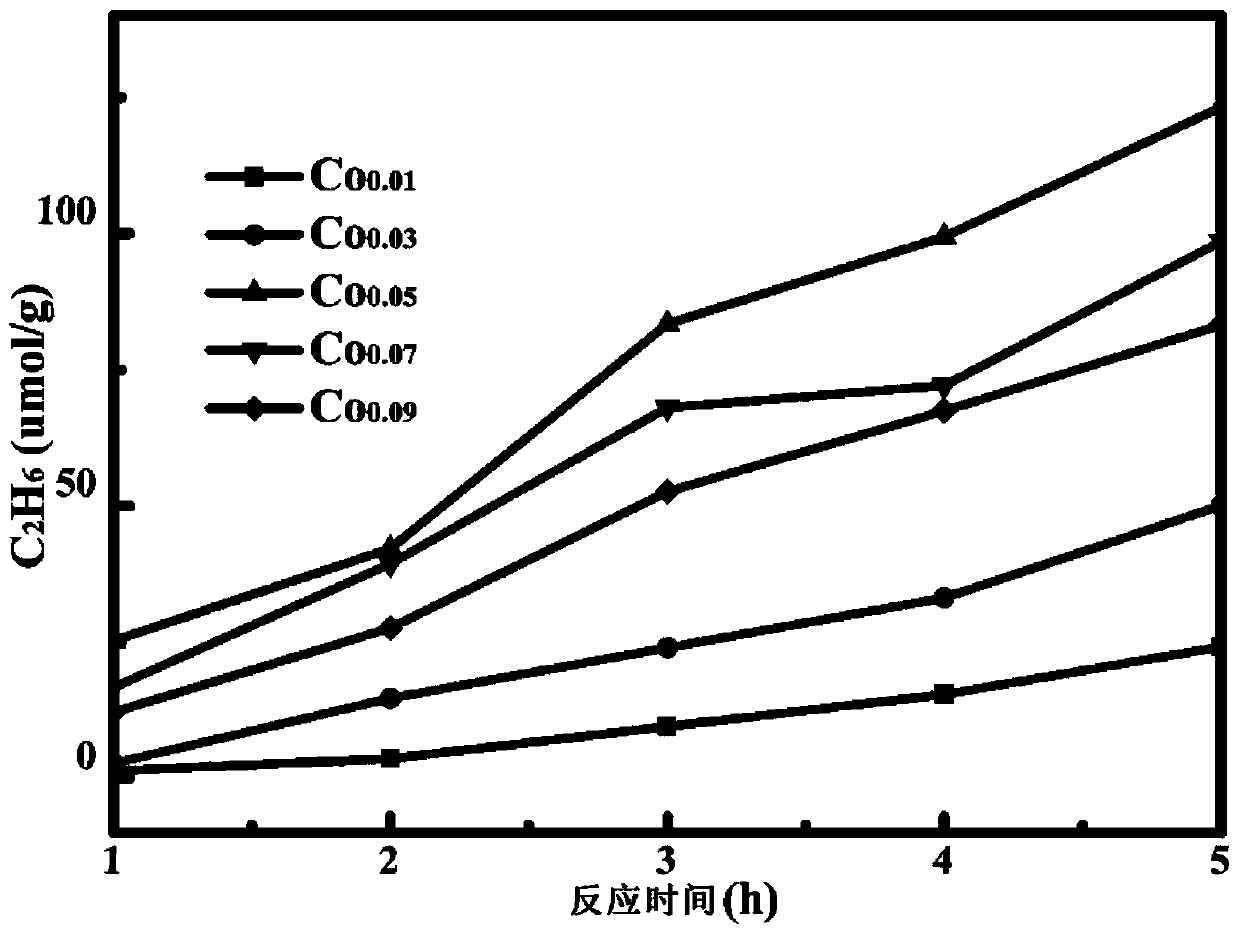

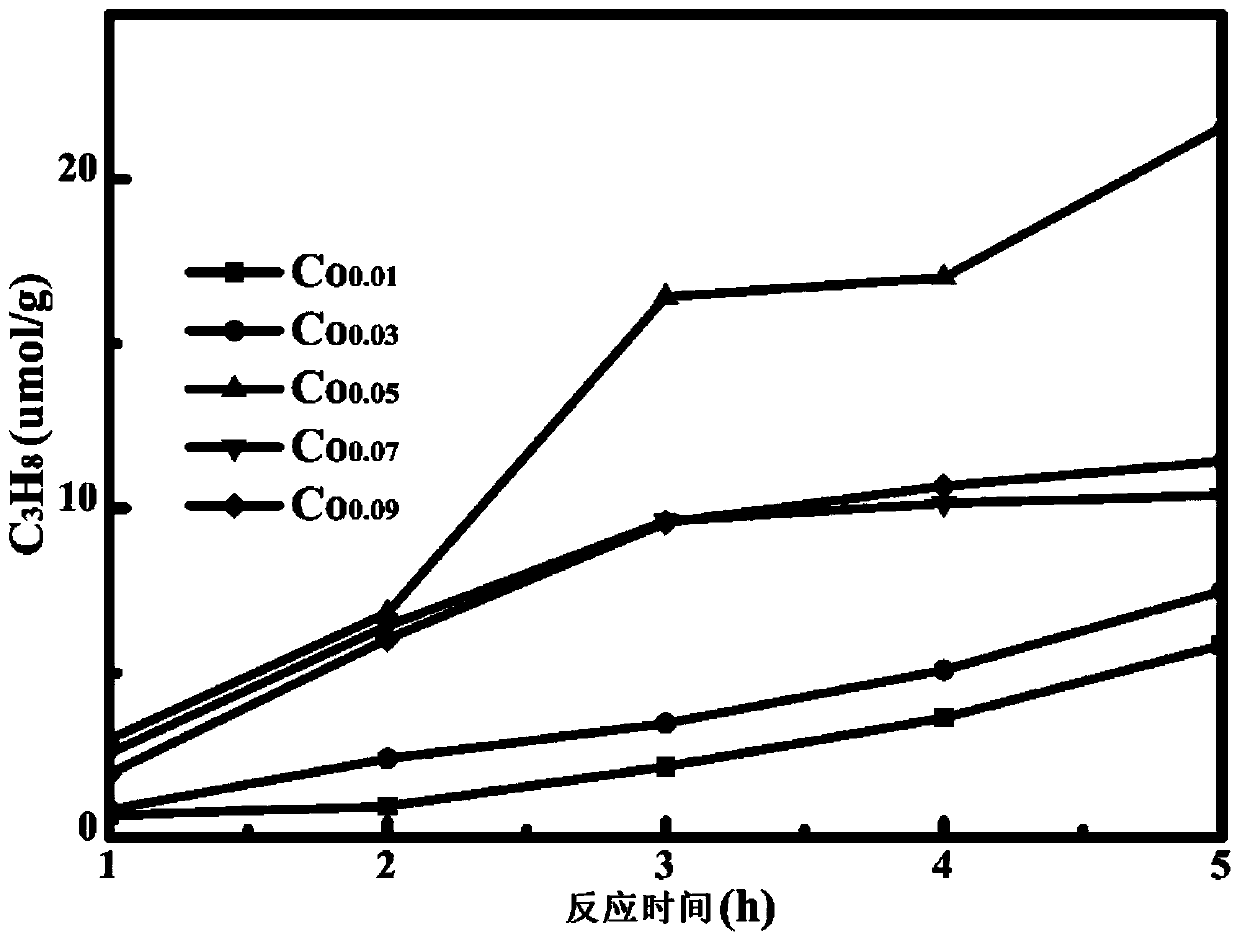

Embodiment 1

[0032] Photocatalyst Ba(Zr 0.5 Ce 0.3 Y 0.2 ) 0.99 co 0.01 o 3-δ The preparation method:

[0033] (1) First prepare a certain concentration of grinding liquid (including water as a solvent, wherein, containing 0.5wt% of PVA, 1wt% of PEG, 1wt% of PAA), with NH 3 ·H 2 O adjusts the pH value to pH=10;

[0034] (2) Weigh BaCO with a molar mass of 0.1mol (19.7340g) 3According to the stoichiometric ratio, weigh 6.0994g, 5.1120g, 4.4710g, 0.0749g of ZrO 2 , CeO 2 , Y 2 o 3 , CoO is placed in a polytetrafluoroethylene ball mill jar;

[0035] (3) Measure 5% of PVA, 1% of PEG, and 10mL of 1% of PAA with a measuring cylinder and pour them into the ball milling jar, then weigh 100g of zirconia ball milling beads, mix them with the sample prepared in the previous stage, and place Take out after 5 hours of rolling ball milling in the planetary ball mill, pour the taken-out ground sample into a freeze-drying tray, and place it in a four-ring freeze dryer to dry;

[0036] (4) Pl...

Embodiment 2

[0039] Photocatalyst Ba(Zr 0.5 Ce 0.3 Y 0.2 ) 0.97 co 0.03 o 3-δ The preparation method:

[0040] (1) First prepare a certain concentration of grinding liquid (including water as a solvent, wherein, containing 0.5wt% of PVA, 1wt% of PEG, 1wt% of PAA), with NH 3 ·H 2 O adjusts the pH value to pH=10;

[0041] (2) Weigh BaCO with a molar mass of 0.1mol (19.7340g) 3 According to the stoichiometric ratio, weigh 5.9762g, 5.0087g, 4.3807g, 0.2248g of ZrO 2 , CeO 2 , Y 2 o 3 , CoO is placed in a polytetrafluoroethylene ball mill jar;

[0042] (3) Measure 5% of PVA, 1% of PEG, and 10mL of 1% of PAA with a measuring cylinder and pour them into the ball milling jar, then weigh 100g of zirconia ball milling beads, mix them with the sample prepared in the previous stage, and place Take out after 5 hours of rolling ball milling in the planetary ball mill, pour the taken-out ground sample into a freeze-drying tray, and place it in a four-ring freeze dryer to dry;

[0043] (4) P...

Embodiment 3

[0046] Photocatalyst Ba(Zr 0.5 Ce 0.3 Y 0.2 ) 0.95 co 0.05 o 3-δ The preparation method:

[0047] (1) First prepare a certain concentration of grinding liquid (including water as a solvent, wherein, containing 0.5wt% of PVA, 1wt% of PEG, 1wt% of PAA), with NH 3 ·H 2 O adjusts the pH value to pH=10;

[0048] (2) Weigh BaCO with a molar mass of 0.1mol (19.7340g) 3 According to the stoichiometric ratio, weigh 5.8530g, 4.9054g, 4.2904g, 0.3747g of ZrO 2 , CeO 2 , Y 2 o 3 , CoO is placed in a polytetrafluoroethylene ball mill jar;

[0049] (3) Measure 5% of PVA, 1% of PEG, and 10mL of 1% of PAA with a measuring cylinder and pour them into the ball milling jar, then weigh 100g of zirconia ball milling beads, mix them with the sample prepared in the previous stage, and place Take out after 5 hours of rolling ball milling in the planetary ball mill, pour the taken-out ground sample into a freeze-drying tray, and place it in a four-ring freeze dryer to dry;

[0050] (4) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com