Mn and Co co-promoted cobaltosic oxide/silicon dioxide catalyst as well as preparation method and application thereof

A technology of cobalt tetroxide and silica, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of narrow temperature window and difficult control of working window, etc. Achieve the effect of low operating window temperature, increased activity and stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

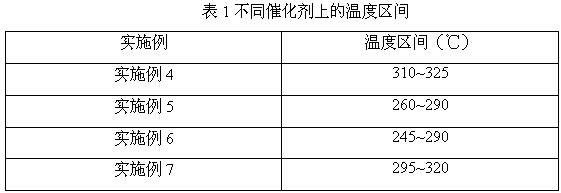

Examples

Embodiment 1

[0032] A Co-promoted SiO 2 Carrier, prepared according to the following steps:

[0033] (1) According to the molar ratio n(Co):n(Si)=1:20, measure 5ml tetraethyl orthosilicate, weigh 0.24g cobalt chloride hexahydrate and dissolve in V 1 =100ml of ethanol, and ultrasonically dispersed for 30min to obtain a mixed solution;

[0034] (2) Continue to add the volume V dropwise to the above mixed solution under the condition of ultrasound 2 = 4ml of deionized water to make V 1 :V 2 =25:1, continue ultrasound for 2h;

[0035] (3) Add volume V drop by drop 3 =: 8ml ammonia water, so that the volume ratio V 2 :V 3 =1:2, continue to sonicate for 5 hours, and get precipitation;

[0036] (4) The obtained precipitate was filtered, washed with ethanol for 5 times, and then washed with deionized water for 3 times to obtain the washed precipitate;

[0037] (5) After the washed precipitate was dried at 60°C for 12h, it was calcined in air at 500°C for 3h to obtain Co-promoted SiO 2 Th...

Embodiment 2

[0039] A Co-promoted SiO 2 Carrier, other steps are the same as in Example 1, just take ethyl orthosilicate and cobalt chloride hexahydrate according to the molar ratio n(Co):n(Si)=1:25, prepare according to the following steps:

[0040] Measure 6ml of tetraethyl orthosilicate, weigh 0.24g of cobalt dichloride hexahydrate, and all the other experimental steps are the same as in Example 1 to obtain Co-promoted SiO 2 Carrier, recorded as Si25Co1 carrier.

Embodiment 3

[0042] A Co-promoted SiO 2 Carrier, other steps are the same as in Example 1, just take tetraethyl orthosilicate and cobalt chloride hexahydrate according to the molar ratio n(Co):n(Si)=1:30, prepare according to the following steps:

[0043] Measure 7ml tetraethyl orthosilicate, weigh 0.24g cobalt dichloride hexahydrate, and all the other experimental steps are the same as in Example 1 to obtain Co-promoted SiO2 The carrier is denoted as Si30Co1 carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com