Super-hydrophobic CMF-TiO2-PDMS composite material, and preparation method and application thereof

A composite material, super-hydrophobic technology, applied in the field of super-hydrophobic CMF-TiO2-PDMS composite material and its preparation, can solve the problems of poor oil-soluble pollutants, easy decomposition, etc., to solve the problems of poor stability and good durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 CMF

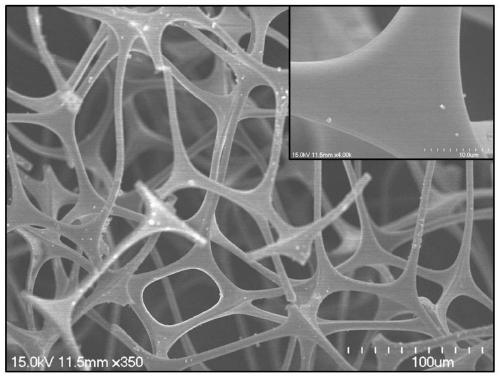

[0032] Commercial melamine foam (10cm x 6cm x 2cm) was put into a tube furnace and heated to 800°C under a nitrogen atmosphere with a heating rate controlled at 5°C / min. And heat treatment at 800 °C for 2 hours, then naturally cooled to room temperature to obtain carbonized CMF. The carbonized CMF is scanned by an electron microscope, and the scanning diagram is shown in figure 1 , figure 1 It is shown that the interior of CMF is composed of cross-linked porous structures with pore sizes ranging from tens of microns to hundreds of microns. This three-dimensional porous structure provides space for the adsorption of pollutants. The enlarged view shows that the surface of the CMF skeleton is very smooth.

Embodiment 2

[0033] Example 2 CMF-TiO 2 Preparation of composite materials

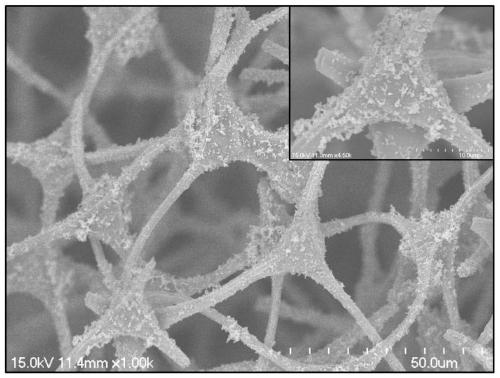

[0034] Take 40 parts of isopropanol, 10 parts of N-N dimethylformamide, and 5 parts of n-tetrabutyl titanate in a beaker, soak the CMF prepared in Example 1 in the above mixed solution, and transfer it to an autoclave, and put Put it into a high-temperature oven for hydrothermal reaction, the reaction condition is 180°C, and the time is 12h; then the product is taken out, washed with 50 parts of isopropanol, and dried in an oven at 80°C; finally, the above foam is put into a tube furnace Carry out high temperature treatment, the temperature is 450°C, the heating rate is 5°C / min, and the time is 2h. CMF-TiO 2 The composite material is scanned by electron microscope, and the scanning picture is shown in figure 2 , figure 2 As shown, the surface of CMF syntactic foam is evenly covered with a layer of TiO 2 Particles, TiO can be seen more clearly from its enlarged view 2 stacked on the CMF framework, indicatin...

Embodiment 3

[0035] Example 3 CMF-TiO 2 - Preparation of PDMS composites

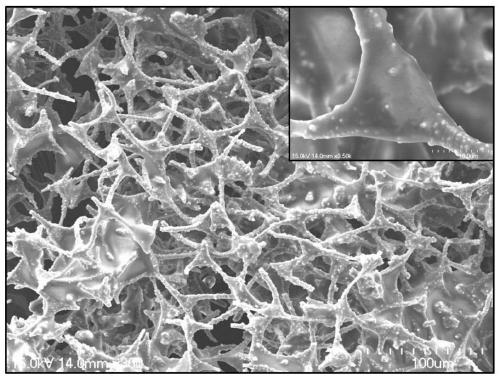

[0036] Get 2 parts of PDMS, 0.2 part of curing agent PDMS prepolymer Sylgard 184, 20 parts of ethyl acetate in a beaker, the CMF-TiO prepared in Example 2 2 Soak in this solution for 1h, fully absorb, and finally put CMF-TiO 2 Take it out and put it into an oven at 120°C for 0.5h to get superhydrophobic CMF-TiO 2 - PDMS composite material. The superhydrophobic CMF-TiO 2 -PDMS composite material is scanned by electron microscope, the scanning picture is shown in image 3 , image 3 show that the TiO 2 The surface is coated with a layer of polymer, indicating that PDMS has been successfully modified to TiO 2 surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com