Method and equipment for preparing easily dispersed aluminum powder pigment through direct ball milling

A technology that is easy to disperse and aluminum powder is applied in separation methods, inorganic pigment treatment, chemical instruments and methods, etc. It can solve the problems of high energy consumption, high cost, cumbersome operation of aluminum powder pigments, etc., and achieve low energy consumption and prevent oxidation , The effect of streamlining equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

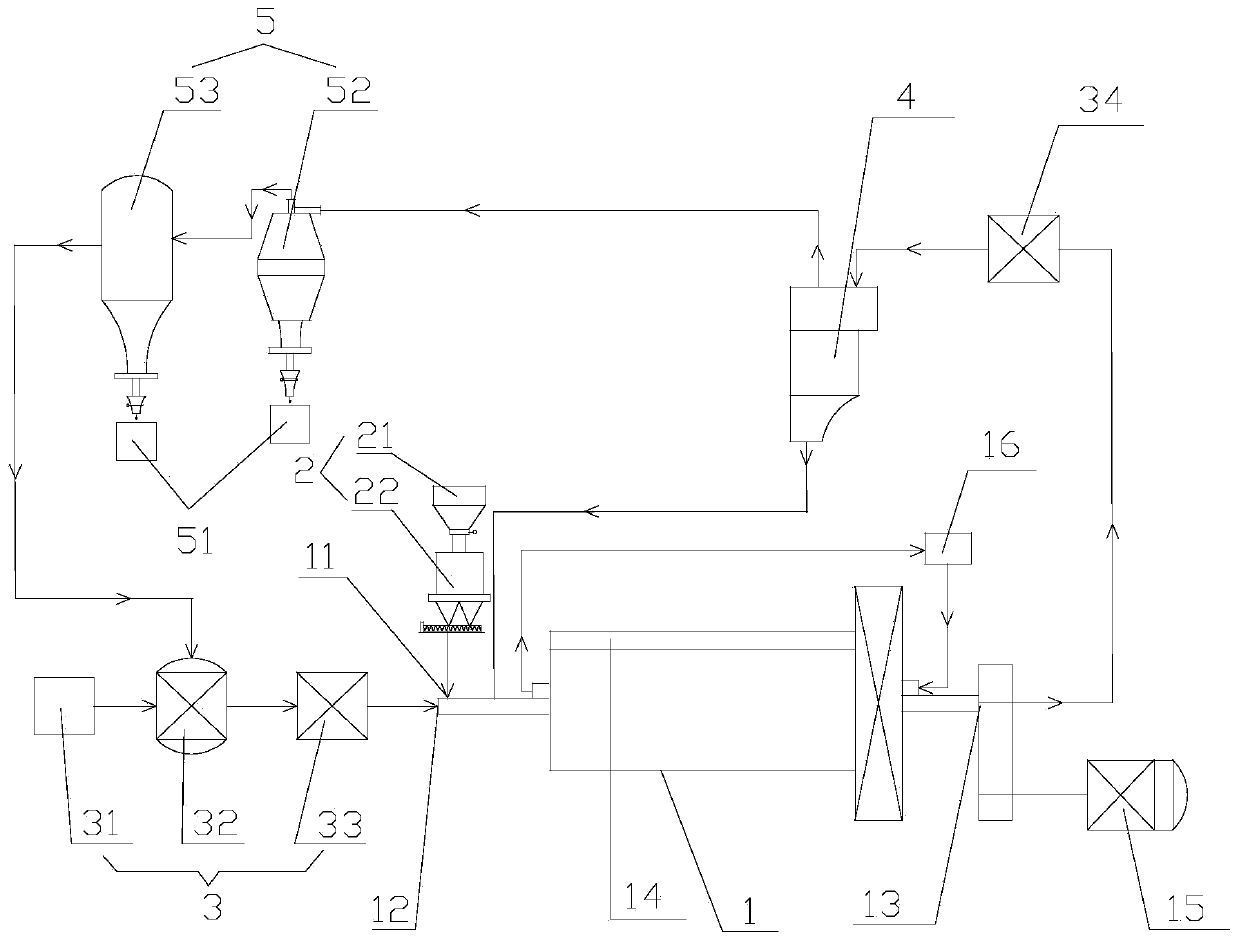

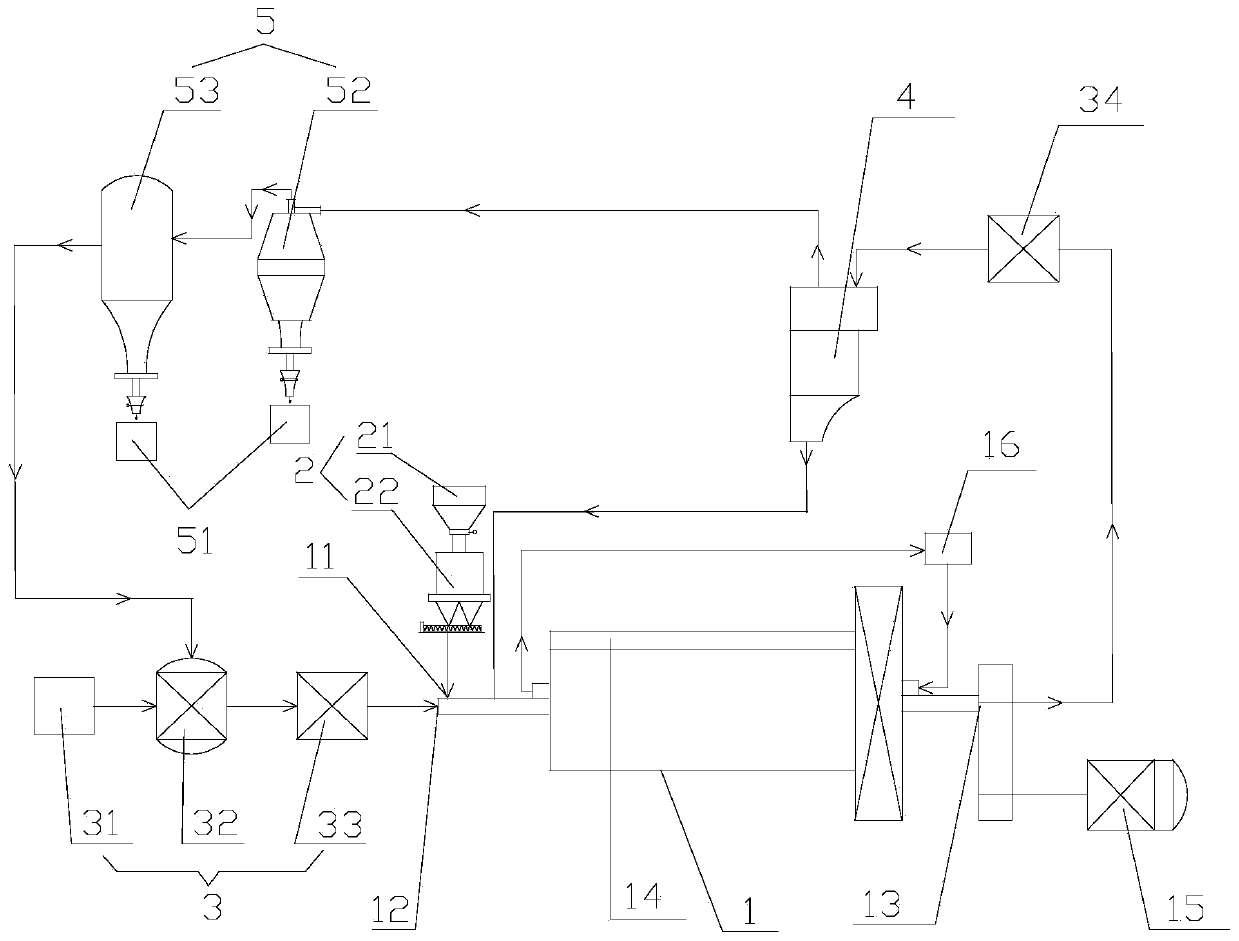

[0046] 1) use figure 1 For the equipment shown, nitrogen gas is blown into the ball mill 1 with grinding balls added in advance, and aluminum powder pigments, acrylic resins, and ball milling aids with a particle size of 8-10 μm are added to the ball mill 1 for grinding, and the heat generated by the grinding makes the resin It becomes glassy and coated on the surface of aluminum powder pigment, wherein, the mass ratio of aluminum powder pigment: resin powder: ball milling aid is 1: 0.2: 0.05, and the mass ratio of grinding ball to the sum of the mass of aluminum powder pigment and resin 1:0.5, the glass transition temperature of acrylic resin is 60°C, adjust the flow rate and temperature of the cooling medium circulation system 16, so that the temperature of the hot zone of the ball mill 1 is 60-65°C, and the temperature of the cold zone is 25-50°C.

[0047] 2) The aluminum powder and pigment powder raised during the ball milling process is discharged from the discharge port ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com