Backfill grouting slurry and grouting process with controllable setting time, and grouting device

A technology of grouting and setting time behind the wall, which is applied in the fields of grouting grouting, grouting process and grouting device, can solve the problems of improper filling of shield tail gaps, long grouting time, and hoop shield tail, etc. The risk of blockage, the controllable coagulation time, and the effect of preventing the floating of the segment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

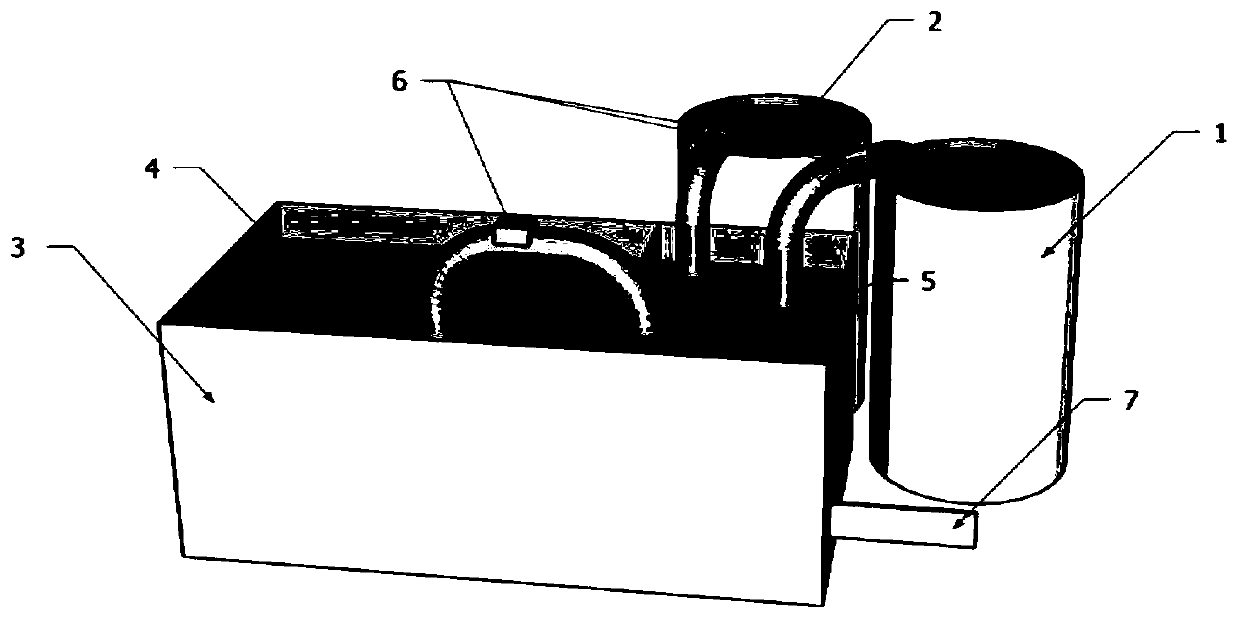

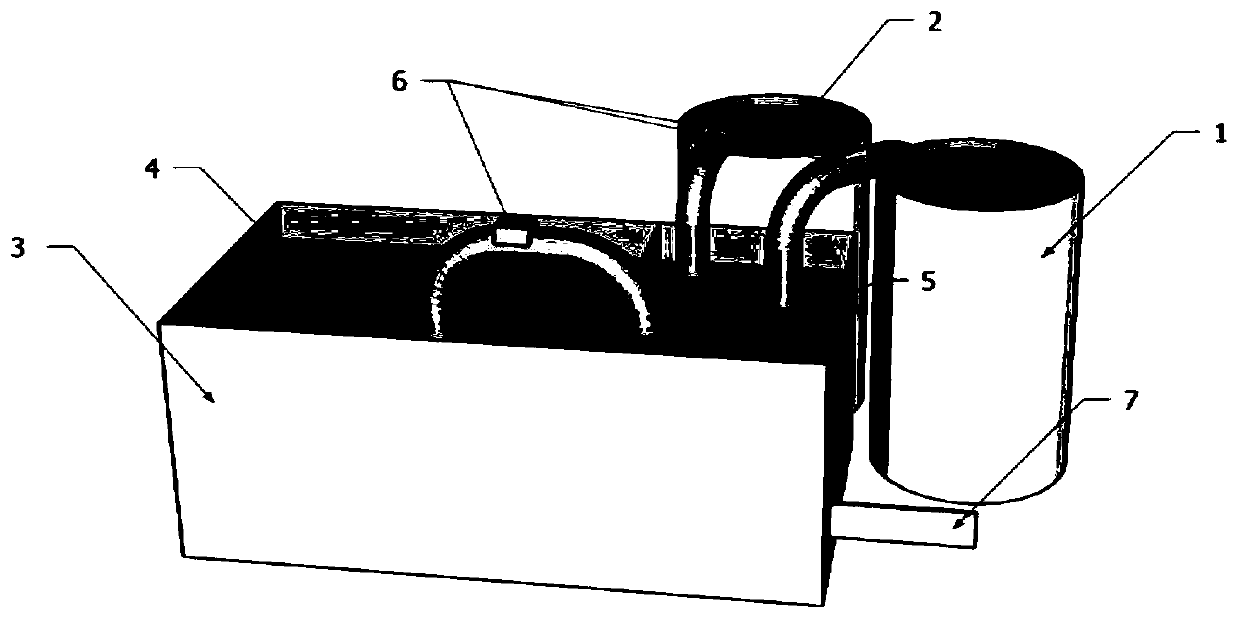

Image

Examples

Embodiment 1

[0025] The grouting slurry behind the wall of the present invention includes cement mortar, water glass, and setting retarder; the cement mortar of the present invention can be configured by on-site mixing or purchased commercial slurry, and the cement mortar of this embodiment is configured by the laboratory, and the specific formula As shown in Table 1, the formula of cement mortar can be: cement 50-150kg / m 3 , fly ash 250-400kg / m 3 , sand 850-1100kg / m 3 , Bentonite 50-120kg / m 3 , water 350-500kg / m 3 . The Baume degree of the water glass of the present embodiment is 30-40 ° of B é, and the ratio of silicon dioxide and sodium oxide content in the water glass is 2.8-3, retarder is sodium dihydrogen phosphate, can also be other commonly used retarder agent; the quality of the retarder added in the present embodiment is 10% of the cement quality in the cement mortar; the volume of the water glass added is 5% of the cement mortar volume.

[0026] Table 1 cement mortar labora...

Embodiment 2

[0030] On the basis of Example 1, different from Example 1, the retarder addition of the present embodiment is 5% of the cement mass in the cement mortar; the addition of water glass is 5% of the cement mortar volume, according to the implementation Example 1 test method, the measured coagulation time is 35min.

Embodiment 3

[0032] On the basis of Example 1, different from Example 1, the addition of the retarder of the present embodiment is 8% of the cement quality in the cement mortar; the addition of water glass is 5% of the cement mortar volume, according to The test method of embodiment 1, the recorded coagulation time is 100min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com